Method for rapidly estimating thickness of photosensitive element chip in infrared focal plane detector

A technology of infrared focal plane and photosensitive elements, which is applied in the direction of electrical components, semiconductor/solid-state device testing/measurement, circuits, etc., to achieve the effect of meeting the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the examples.

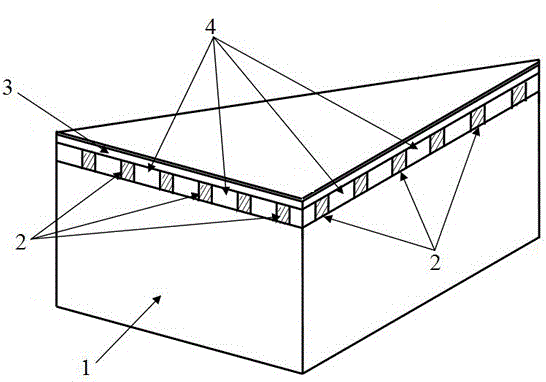

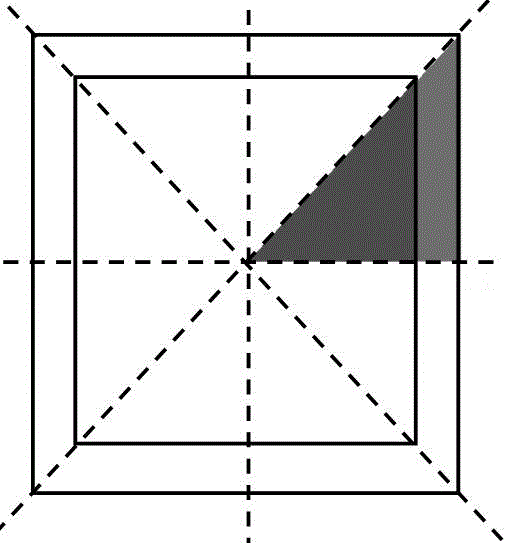

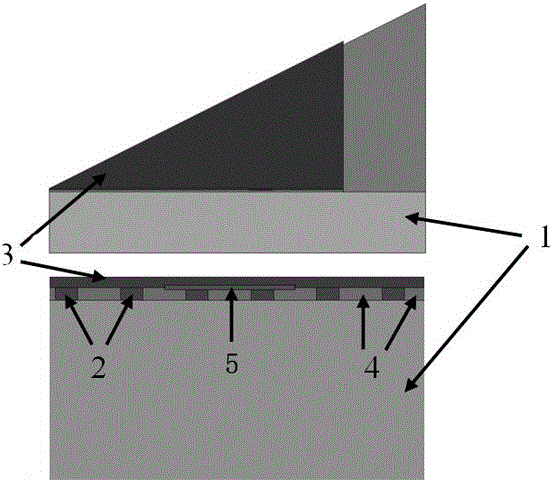

[0024] Deformation analysis of an indium antimonide (InSb) infrared focal plane detector with a scale of 128×128 arrays. The detector is composed of an InSb photosensitive element chip and a silicon readout circuit interconnected through an indium column array, and then an underfill glue is filled in the gap between the photosensitive element chip and the silicon readout circuit.

[0025] The simulation process is as follows:

[0026] 1) The viscoplastic model is used for the indium column, the viscoelastic Maxwell model is used for the bottom filling, and the linear elastic model is used for the photosensitive element chip, negative electrode and silicon readout circuit to conduct direct coupling field analysis;

[0027] 2) Input the Young's modulus, linear expansion coefficient, Poisson's ratio and density of the photosensitive element chip, the interconnected indium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com