Packaging structure of radio frequency filtration module and packaging technology of packaging structure

A technology of radio frequency filtering and packaging structure, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor heat dissipation effect of injection molding materials, complicated processes, and unfavorable heat dissipation of high-power components, and achieve improved heat dissipation effect and simple process. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

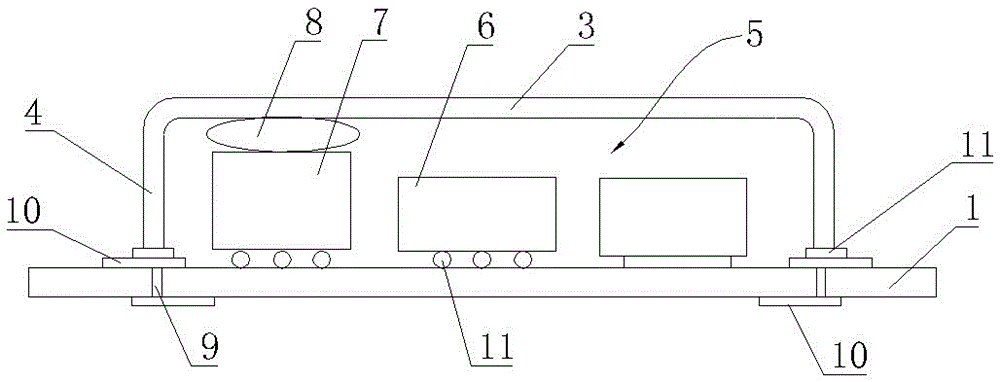

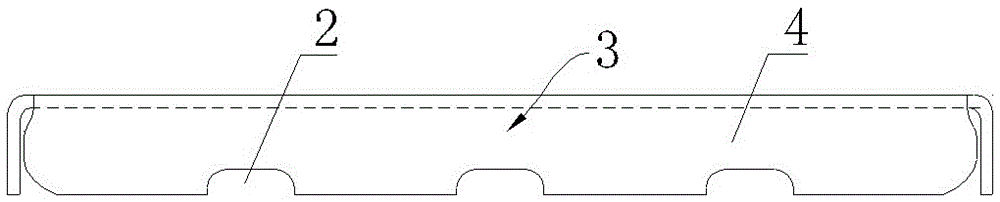

[0020] See figure 1 , figure 2 , a packaging structure of a radio frequency filter module, including a substrate 1 and a chip arranged on the front surface of the substrate 1, and also includes a metal shielding cover 3, and the four sides of the metal shielding cover 3 extend vertically downward to form side walls 4 and form a package The cavity 5, the metal shielding cover 5 covering the substrate 1 can package the chip in the packaging cavity 5, the chip includes a surface acoustic wave filter chip 6, a radio frequency power amplifier 7, an auxiliary resistor and an auxiliary capacitor, and the surface acoustic wave filter chip 6 , the power amplifier 7, the auxiliary resistor and the auxiliary capacitor are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com