LED (Light Emitting Diode) packaging structure and packaging method thereof

A technology of LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to form a flat surface, poor tin-eating ability of pins, design height error, etc., to increase the tin-eating area, The effect of streamlining production processes and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

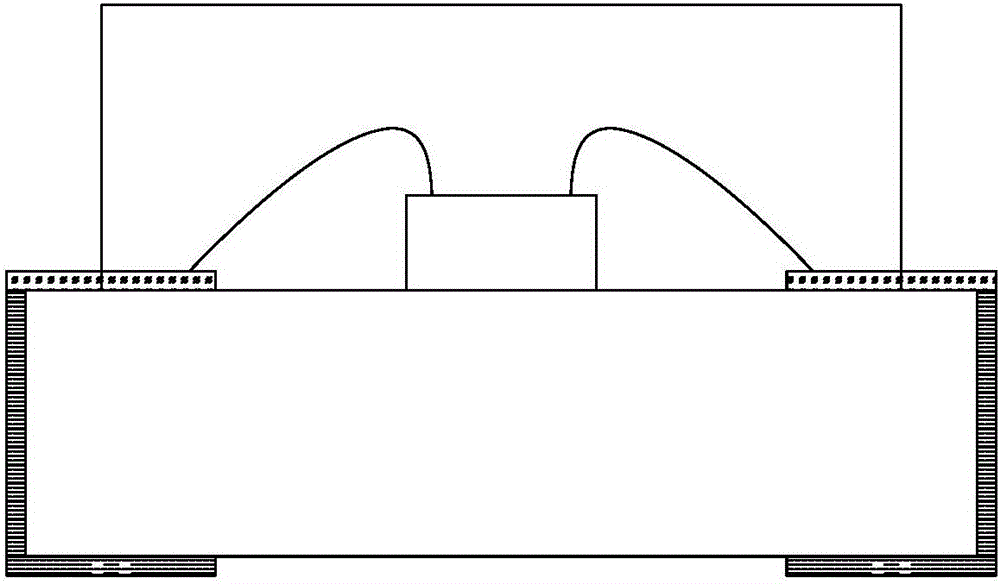

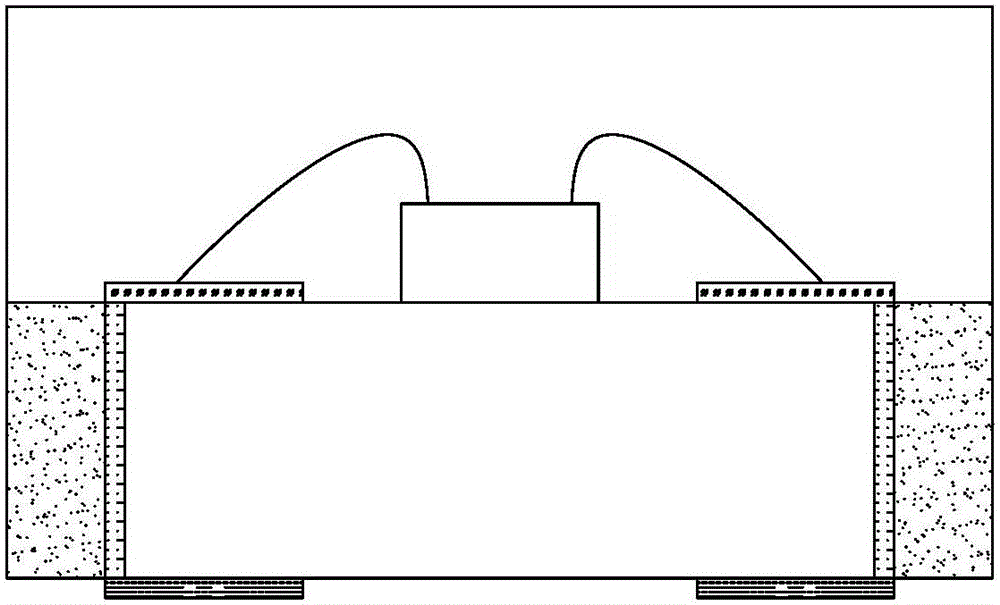

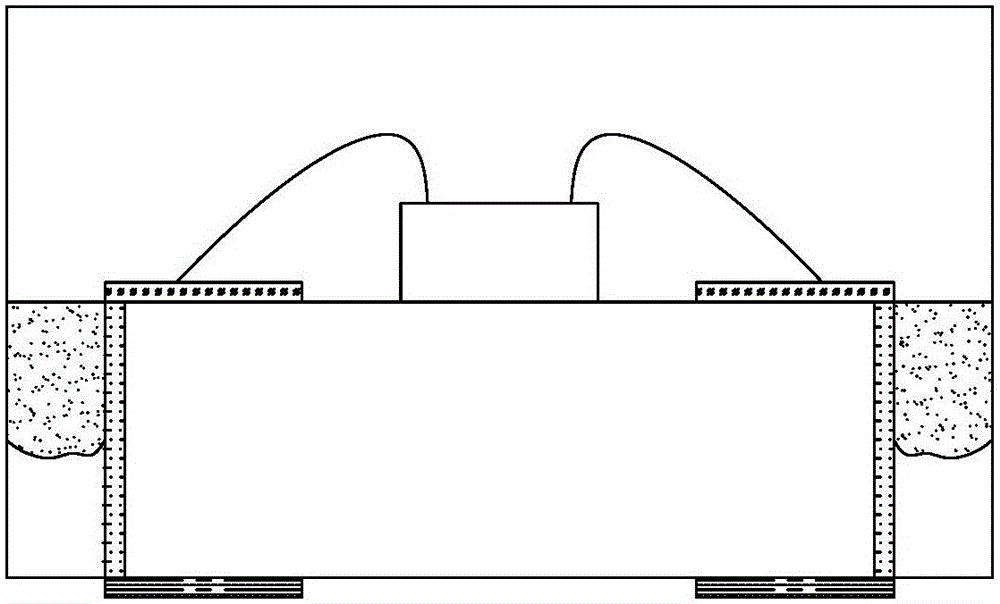

[0035] Such as Figure 4 As shown, an LED packaging structure includes a PCB substrate 1; the upper surface of the PCB substrate 1 is provided with a soldering functional area 2, and the lower surface is fixed with a pin 3; the soldering functional area 2 is electrically connected to the pin 3; The upper surface of the PCB substrate 1 is also provided with an LED chip 4; the LED chip 4 is electrically connected to the solid welding functional area 2 through the bonding wire 5; the upper surface of the PCB substrate 1 is also provided with a colloid 6 for fixing the LED chip 4; 1 includes two layers of plates that are overlapped and fixedly connected together; the lower plate 11 is provided with a first through hole 111, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com