Copper processing method

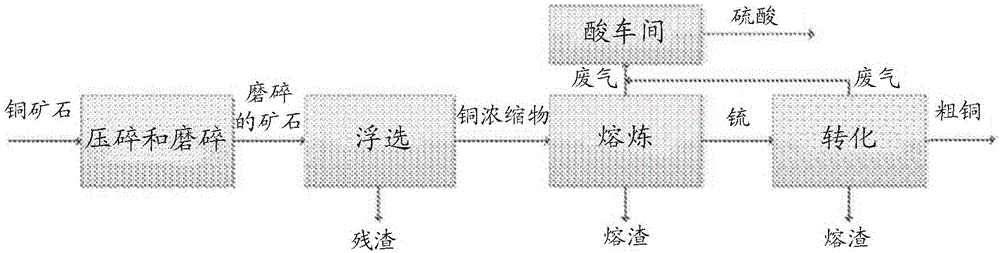

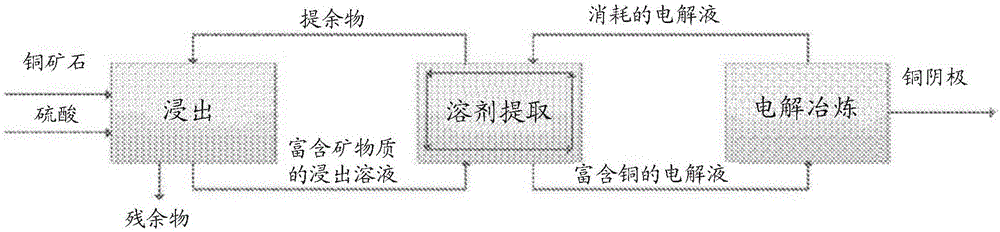

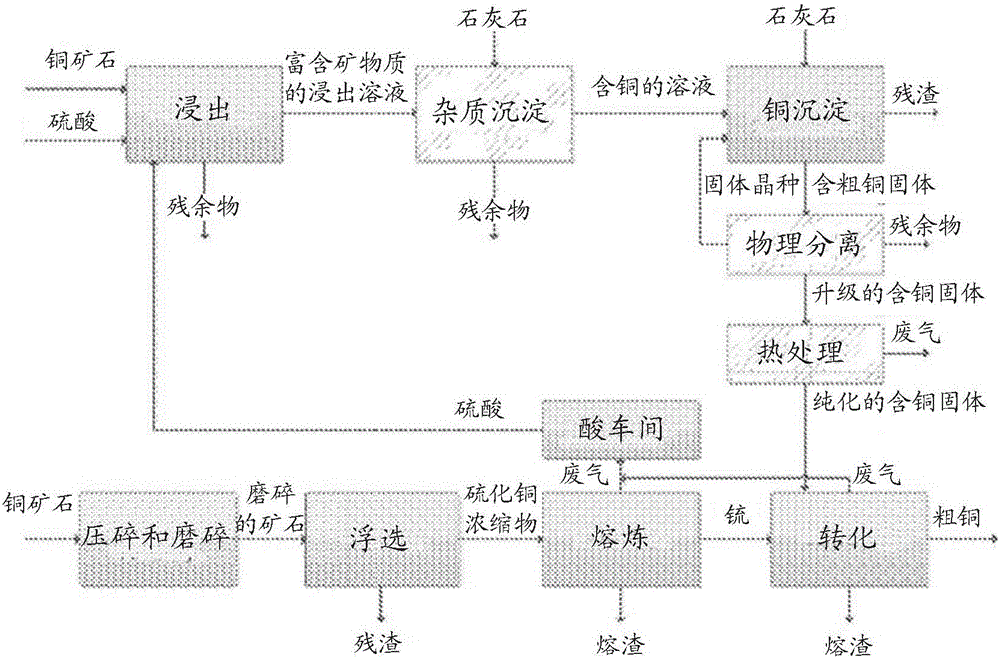

A copper source, copper sulfide technology, applied in the field of processing ore or source materials to recover copper or suitable copper compounds from them, which can solve the problems of increased operating costs of copper production, increased impact of greenhouse gases, increased demand for electrical energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention was at least partially foreseen upon the discovery that a copper concentrate could be precipitated from an aqueous acid leach solution suitable for direct feeding to a smelting or conversion step for thermal decomposition to provide a copper product. The use of lime and / or limestone has been found to be particularly useful in precipitating copper concentrates, which can be advantageously incorporated into smelting / conversion operations. This scheme allows the integration of the early steps of the hydrometallurgical scheme with the downstream steps of the pyrometallurgical scheme, enabling the efficient processing of a wider range of copper ore types and ore grades. Furthermore, it has been shown that copper sulfide ores or concentrates can advantageously be converted to a form that provides the desired solution from which copper concentrates can be precipitated by subjecting the ores or concentrates to oxidative calcination prior to leaching. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com