Furrowing profiling pneumatic type precision vegetable seeder

A pneumatic seeder technology, which is applied to interval quantitative seeding machinery, seeder parts, excavation/covering trenches, etc., can solve the problems of wasting seeds, high labor intensity, low production efficiency, etc., and improve seedling emergence High efficiency, reduced labor intensity, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

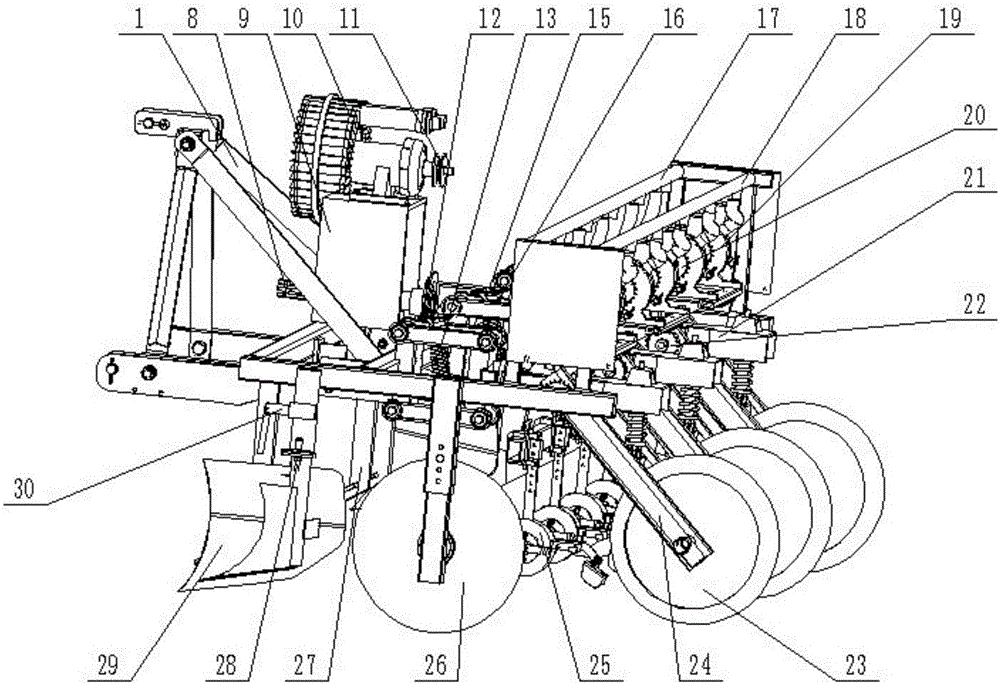

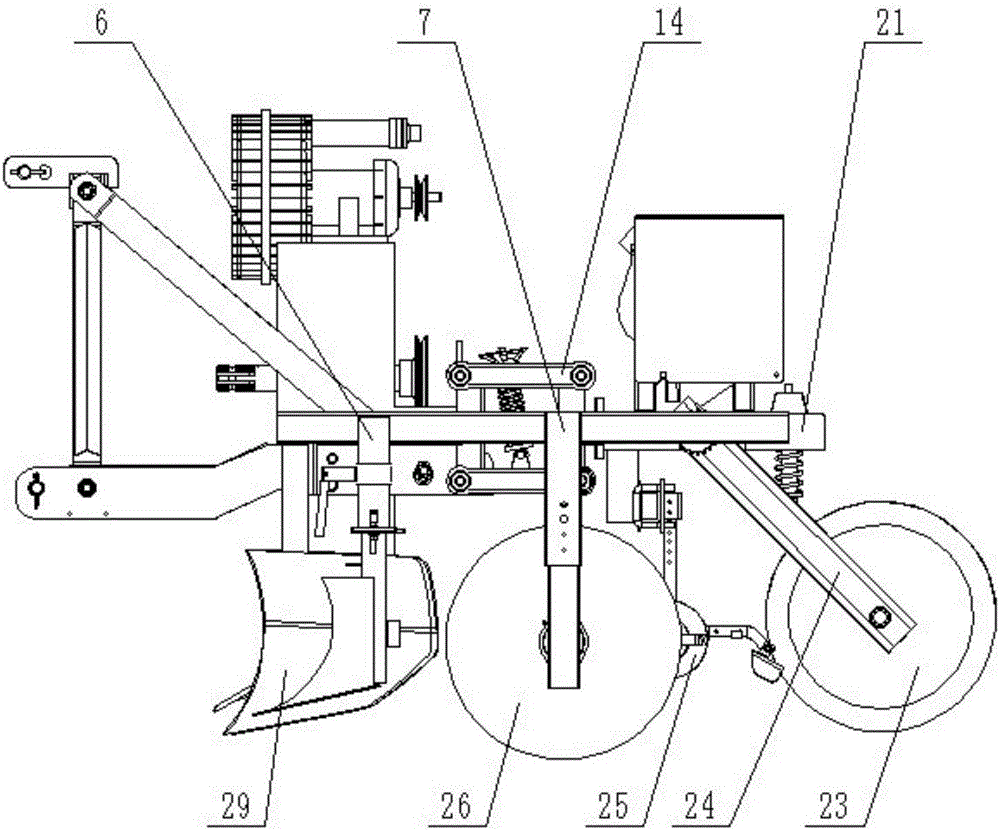

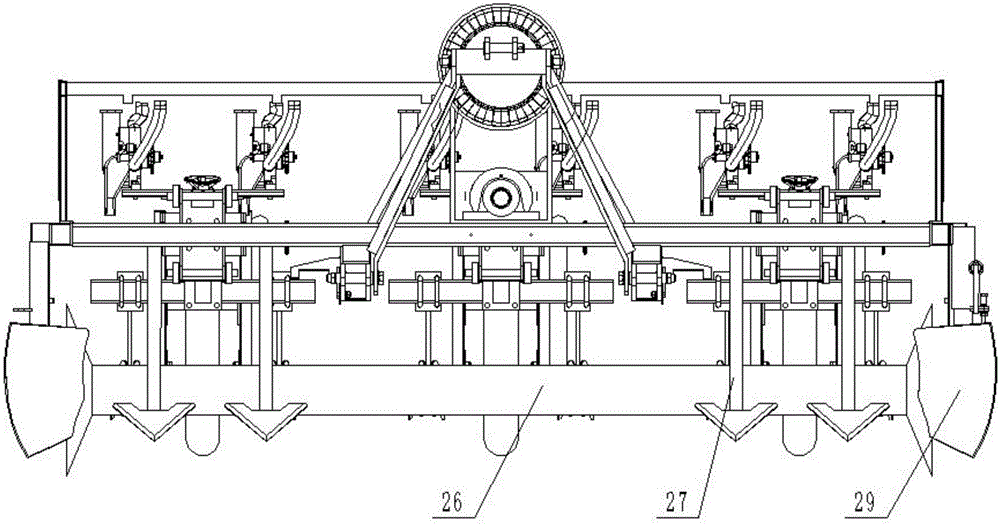

[0025] A ditching profiling pneumatic vegetable precision seeder, comprising a main body frame and a profiling unit, the front end of the main frame is fixed with a three-point suspension frame 1 by bolts, and the three-point suspension frame 1 is used for hanging with a tractor Then, the rear end of the main frame is fixed with a seeding unit, the upper part of the main frame is fixed with a pneumatic unit, the lower part of the main frame is fixed with a furrow opening and shaping unit, and the profiling unit is installed on the main frame superior. The main body frame includes a front beam 2 and a pair of cross beams 4, the rear beam 3 is fixed behind the front beam 2, the front beam 2 and the rear beam 3 are fixed side by side between a pair of cross beams 4, the front beam 2 Both ends are connected to one end of the beam 4, both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com