Robot gripper mechanism with net suction hand

A robot gripper and arm technology, which is applied in the field of low-pressure casting, can solve problems such as complex structure, large space occupied by equipment, and poor reliability, and achieve the effects of ensuring personal safety, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed structure and usage status of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

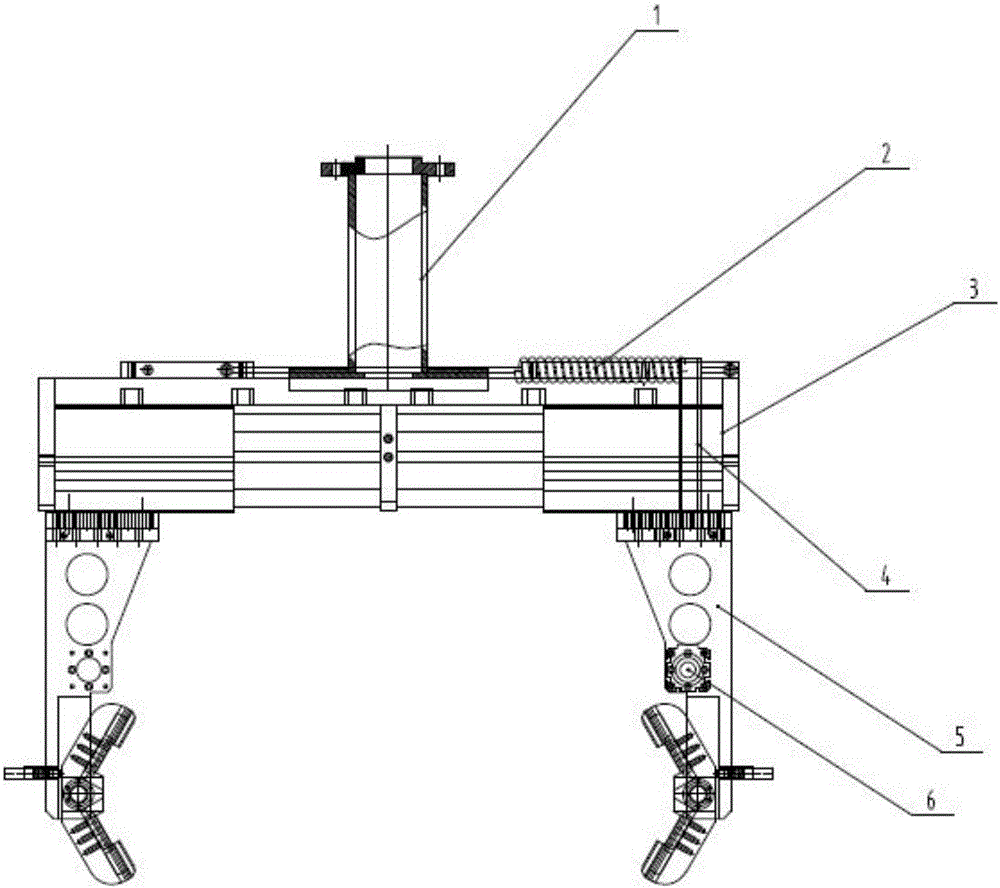

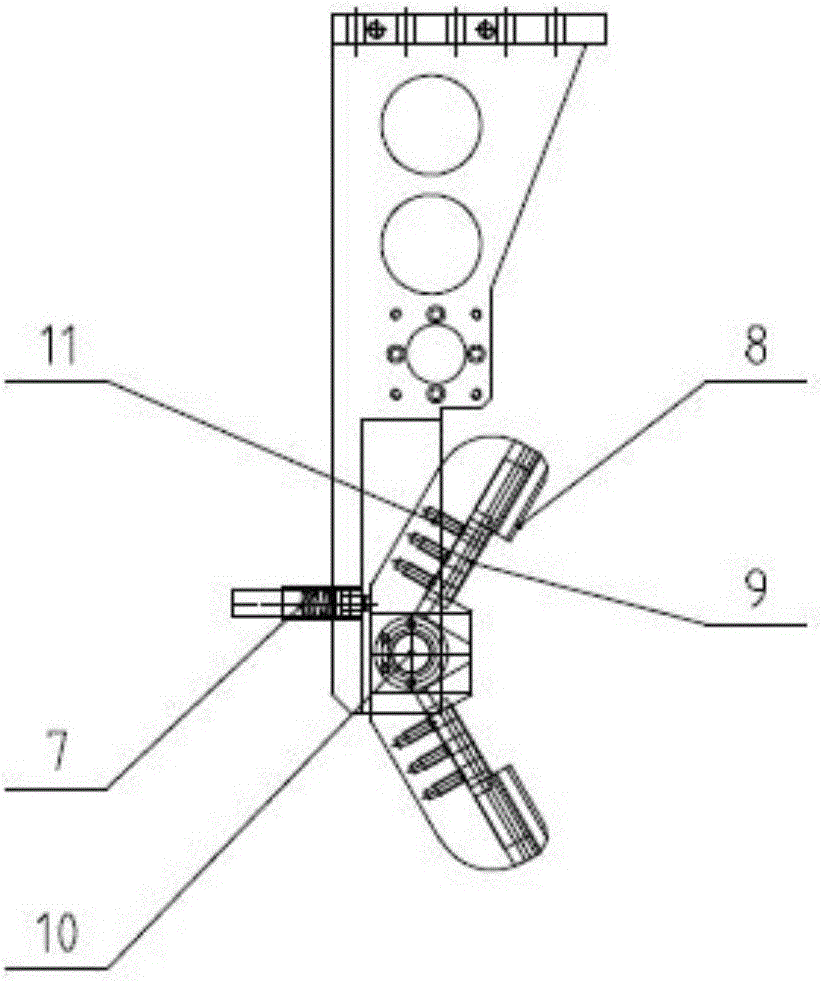

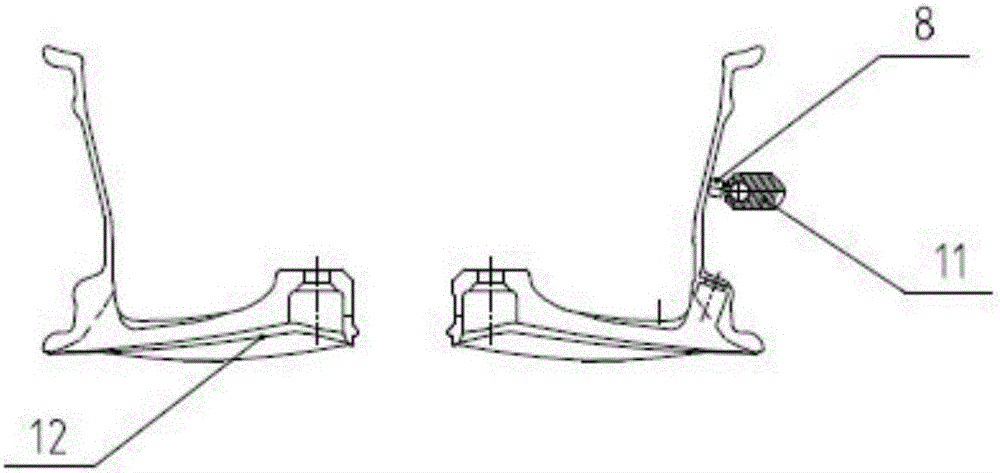

[0022] Such as figure 1 As shown in -4: the structure of the robot gripper assembly of the present invention is as follows: one end of the connector 1 is connected to the six-axis output flange of the robot, the other end is connected to the DESTACO cylinder 3 for grabbing the wheel hub, and the gripper arm 5 is fixed on the DESTACO cylinder 3; Catch the net suction cylinder 6 on the arm simultaneously, the suction net cylinder 6 is an extended single-acting cylinder, and the spiral air pipe 2 one ends pass through the trachea support 4 and are connected with the suction net cylinder 6, and the other end is connected with the electromagnetic valve of control.

[0023] The action of DESTACO cylinder 3 realizes the grasping of the wheel hub, and the robot carries the connecting piece 1 to realize the tra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap