Novel ceramic sheet material and production method thereof

A new type of panel and production method technology, which is applied in the field of interior decoration or furniture panels, can solve the problems of increased panel weight, high manufacturing cost, and veneer acceptance, and achieve the effects of light weight, reduced felling, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

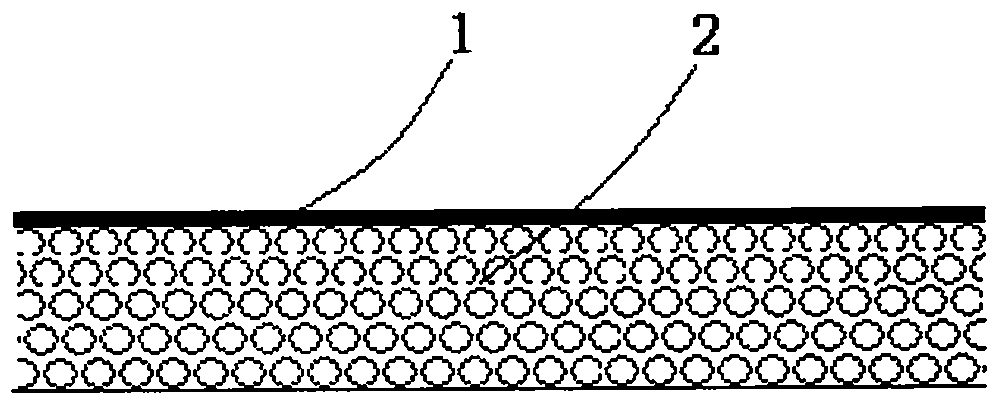

[0023] Such as figure 1 Shown is a single-sided cross-sectional schematic diagram of a new type of ceramic plate. As shown in the figure, the structure of a new ceramic plate includes a ceramic plate 1 and a filler 2 . One side of the ceramic plate 1 is a glazed or polished smooth surface; the other face of the ceramic plate is connected with a filler 2 of equal area; the filler 2 is foamed cement, perlite cement; wherein the thickness of the foamed cement is 1cm -10cm.

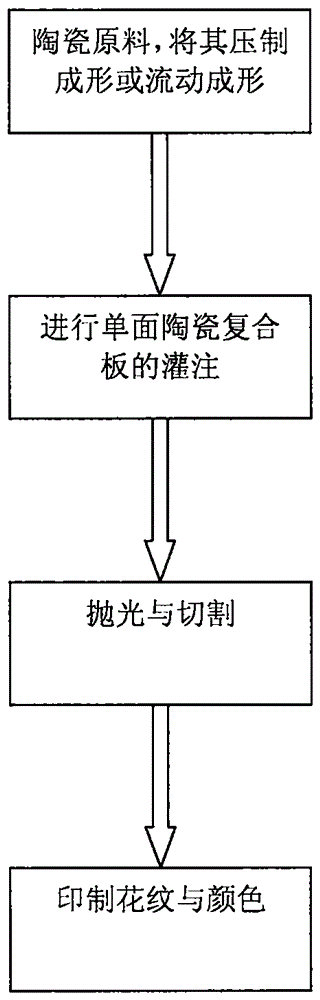

[0024] Such as image 3 Shown is a flow chart of the dust production method of a novel ceramic plate. As shown in the figure, firstly, according to the ceramic raw materials of different properties, they are pressed or flow formed. For the ceramic plates that need to be equipped with small ceramic pillars, polystyrene boards, extruded boards or gypsum boards that are easy to open holes can be used. The low-strength plate is used as the bottom mold, and holes are drilled on the bottom mold according to the...

Embodiment 2

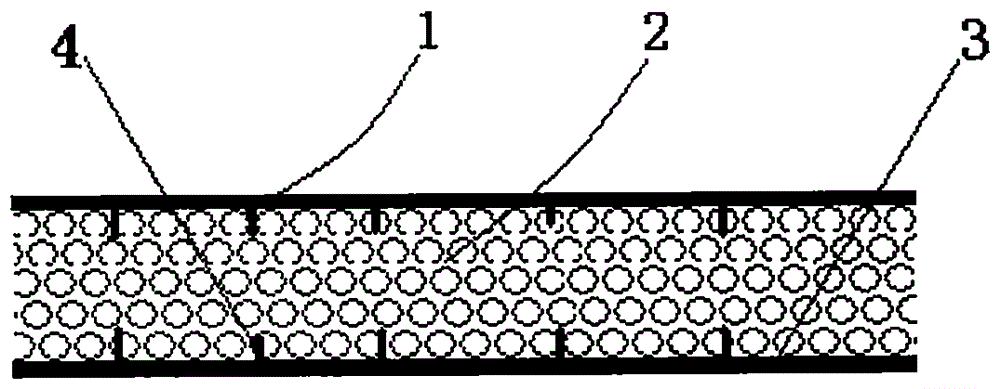

[0029] Such as figure 2 Shown is a double-sided cross-sectional view of a new type of ceramic plate. As shown in the figure, the structure of a new type of board includes a top ceramic board 1 , a filler 2 , and a bottom ceramic board 2 . One side of the top ceramic plate 1 and the bottom ceramic plate 2 is a glazed or polished smooth surface; an equal-area filler is connected between the top ceramic plate 1 and the bottom ceramic plate 2; the filler is foamed cement and perlite cement; Wherein the thickness of the foamed cement is 1em-10cm. The ceramic plate 1 on the top and the ceramic plate 2 on the bottom are provided with bonding posts 4 for increasing the bonding force between the ceramic plate and the filler.

[0030] Such as image 3 Shown is a flow chart of the dust production method of a novel ceramic plate. As shown in the figure, firstly, according to the ceramic raw materials of different properties, they are pressed or flow formed. For the ceramic plates tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com