A molding device and molding method for "I"-shaped parts

A molding device and tooling technology are applied in the field of composite material manufacturing to achieve the effects of avoiding butt operation, tight fit and simple process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

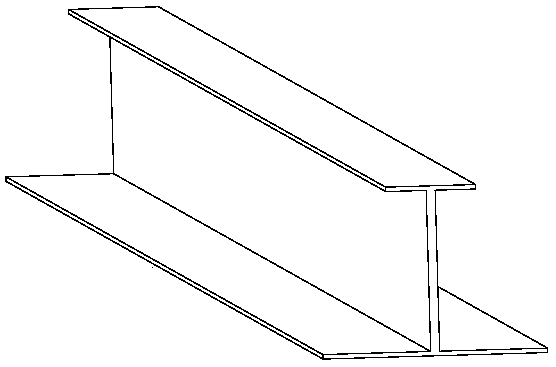

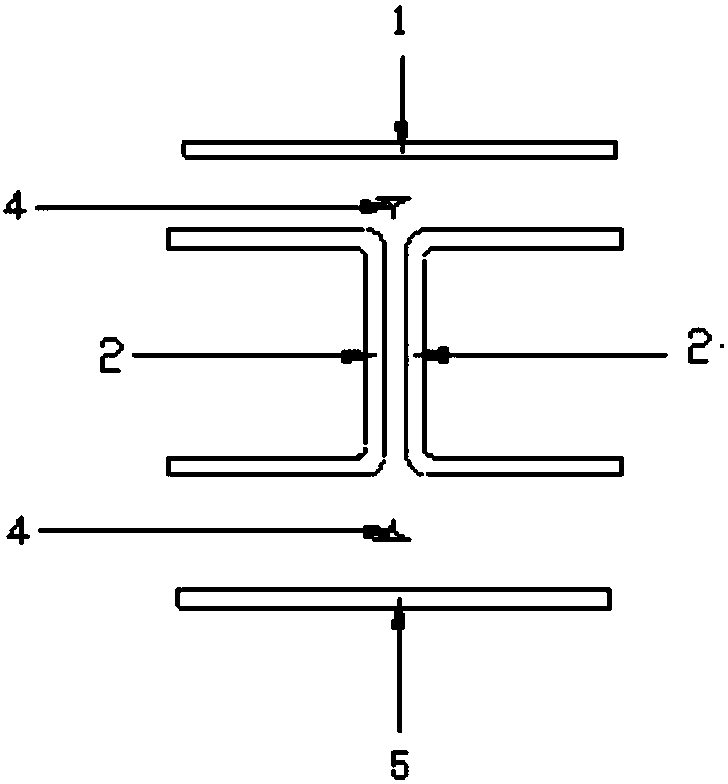

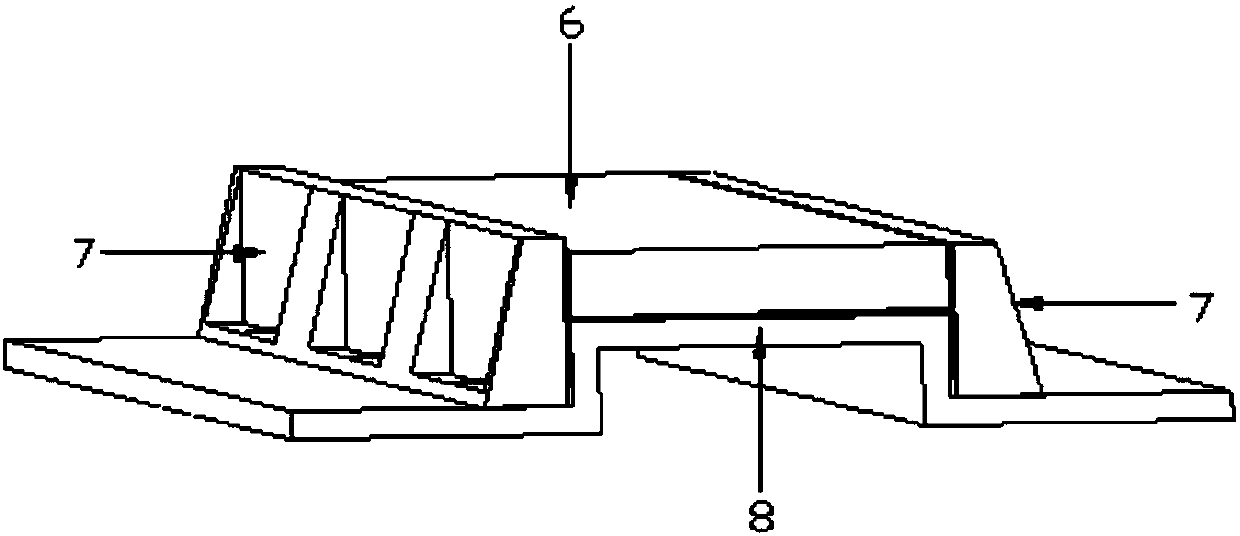

[0032] Such as image 3 , 4 As shown, a forming device for "I"-shaped parts includes a "Ji"-shaped tooling body 8, a positioning block 7, and a non-metallic pressure pad 6. The tooling main body 8 is placed on the bottom layer, and a "C"-shaped structure 2 of the "I"-shaped part is laid on the surface of the tooling main body 8; positioning holes are provided at the corresponding positions of the ears on both sides of the tooling main body 8 and the positioning stopper 7, and the positioning stopper The block 7 is fixed on the ears on both sides of the main body 8 of the tooling, and is used for paving and positioning the upper edge surface 1 and the lower edge surface 5 of the "I"-shaped part; the non-metallic pressure pad 6 is placed on the other "I"-shaped part In the groove of the C”-shaped structure 2, it is used to compress parts and transmit pressure evenly.

[0033] Take the manufacture of "I" shaped long trusses as an example, such as Figure 1-4 As shown, the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com