Water transfer printing paper capable of being printed through water-based printing paste and preparation method of water transfer printing paper

A technology of water transfer and printing paper, which is applied in the process of producing decorative surface effects, papermaking, paper coating, etc. It can solve the problems of affecting the health of production workers, environmental damage, and difficulty in separating from the base paper, so as to facilitate construction and Quality control, use less, make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

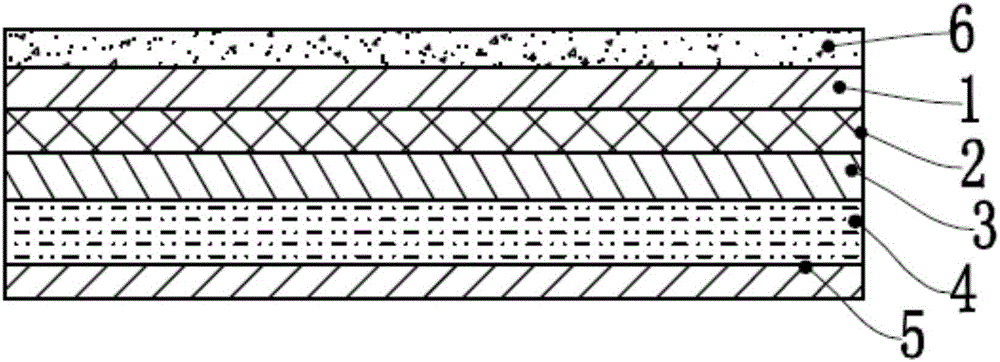

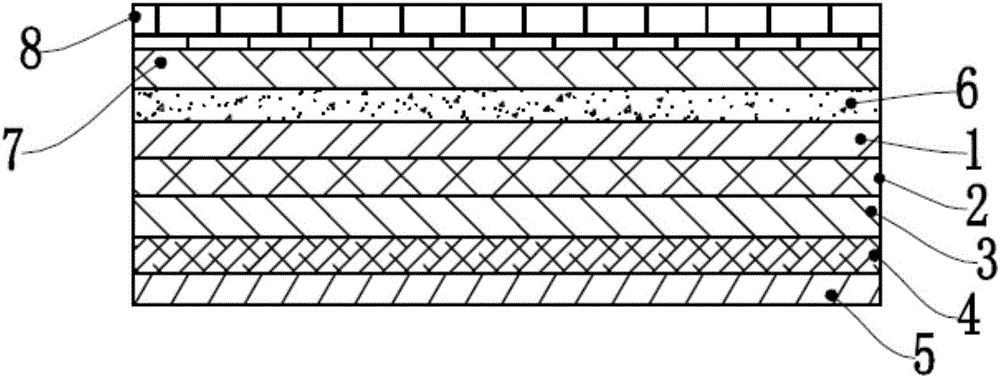

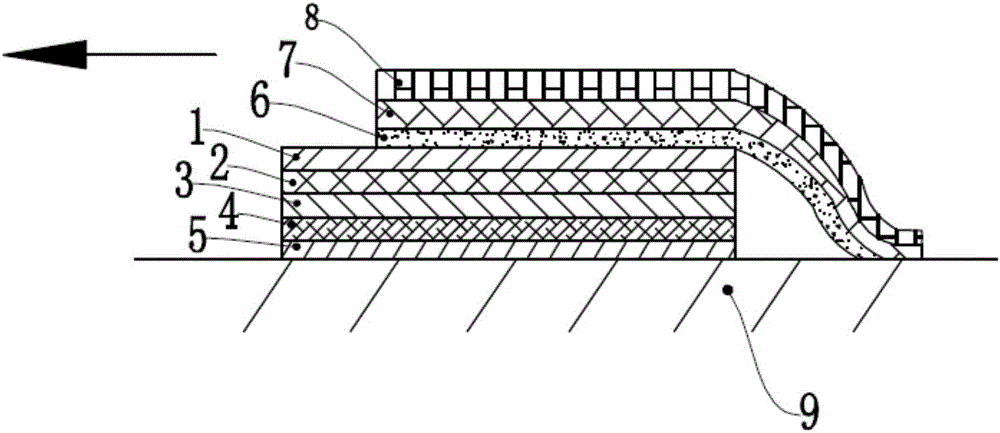

[0029] The water transfer printing paper ( figure 1 Shown), from outside to inside are: surface coating 1, middle coating 2, bottom coating 3, base paper 4 and back coating 5; a hydrophobic coating 6 is also arranged on the surface of surface coating 1.

[0030] The selection of base paper 4 requires suitable bulk, excellent water permeability, low water absorption dimensional change, good surface smoothness, and high stiffness. The bottom coating 3 is often called the primer, and its function is mainly to coat the original rough and uneven paper surface. The coating needs to have water solubility and water permeability. The middle coat 2 requires a balance between good water absorption and gel sliding properties. The surface coating 1 needs to have good water absorption and water resolving proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com