Air-propelled amphibious tidal land ship

An air propulsion and tidal flat technology, applied in air propulsion elements, ship propulsion, amphibious vehicles, etc., can solve problems such as unreliable work, affecting work efficiency, affecting cleaning, etc., to reduce resistance and wave slamming, and reduce viscosity. Frictional resistance, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

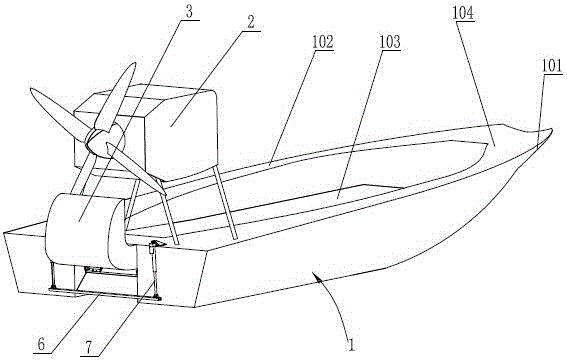

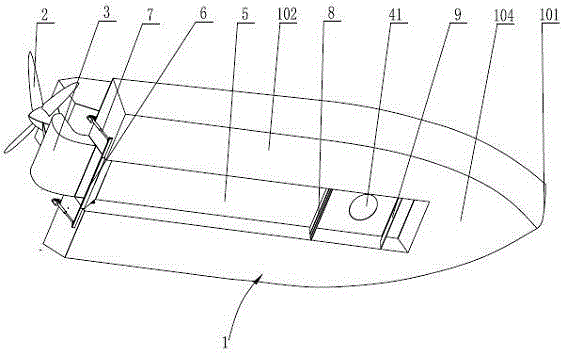

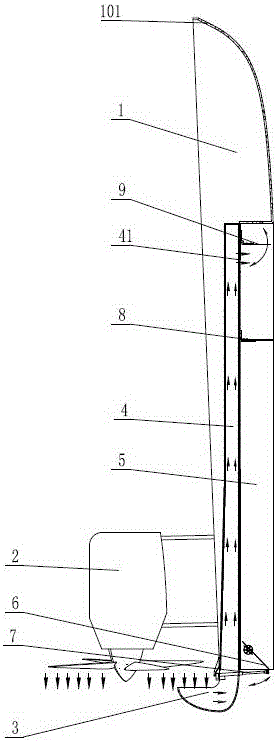

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0032] See figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes a hull 1, an air propeller power unit 2 installed on the deck of the hull 1, the hull 1 is a single bow and double stern structure, and the bow 101 is a tapered bow with a "V" shape in cross section. The rear part of 101 is connected with two longitudinal monoliths 102 through a transition ship section 104 to form the hull 1, and the two monoliths 102 are arranged symmetrically with a transverse interval between them, and the tails of the two monoliths 102 form two parts of the hull 1. At the stern, the two monomers 102 are connected by the connecting bridge 103 on the upper part, and the two monomers 102, the connecting bridge 103 and the transition ship section 104 form a longitudinal padding channel 5 with openings at the bottom and tail, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com