Small automatic fruit packaging machine

A packaging machine and fruit technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of high price, increased volume and cost, and large volume, so as to simplify the structure and volume of the whole machine, reduce types and quantities, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

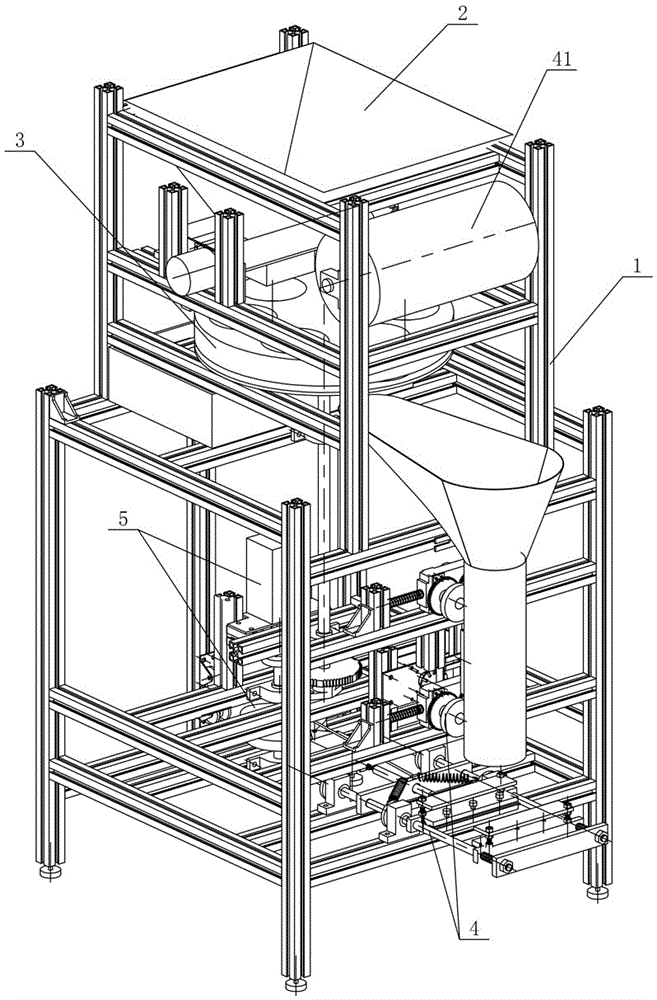

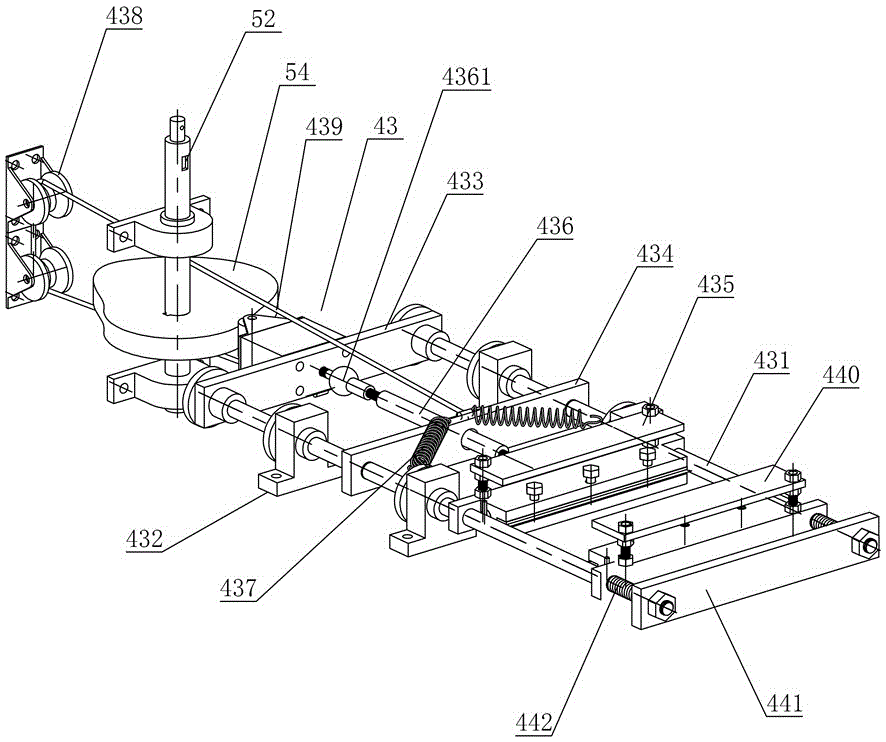

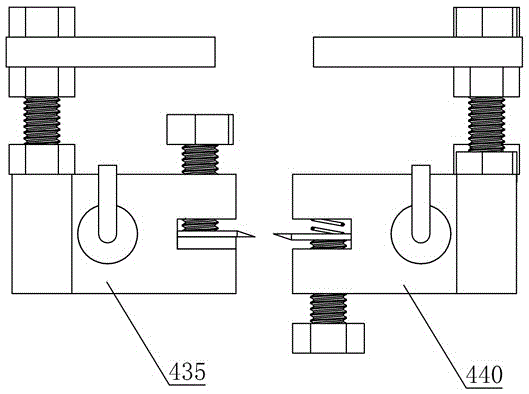

[0033] Figure 1 to Figure 8 Shown is a kind of embodiment of the small automatic fruit packaging machine of the present invention, and this packaging machine comprises frame 1, fruit storage funnel 2, transporting fruit mechanism 3, packaging mechanism 4 and driving mechanism 5, and fruit storage funnel 2 is installed on the machine On the top of the frame 1, the fruit transportation mechanism 3 is installed in the middle of the frame 1 and connected with the fruit storage funnel 2, the packaging mechanism 4 is installed in the lower part of the frame 1 and connected with the fruit transportation mechanism 3, and the driving mechanism 5 is connected with the fruit transportation mechanism 3 at the same time. Connect with packaging mechanism 4. When in use, start the driving mechanism 5, and the fruit enters the packaging mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com