Fault-crossing tunnel deformation coordination type supporting structure and construction method thereof

A technology of deformation coordination and support structure, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of damage, not involving the improvement of the tunnel support structure, difficult to solve the concentrated stress of the tunnel support structure, etc. Suitability and durability, effect of reducing local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

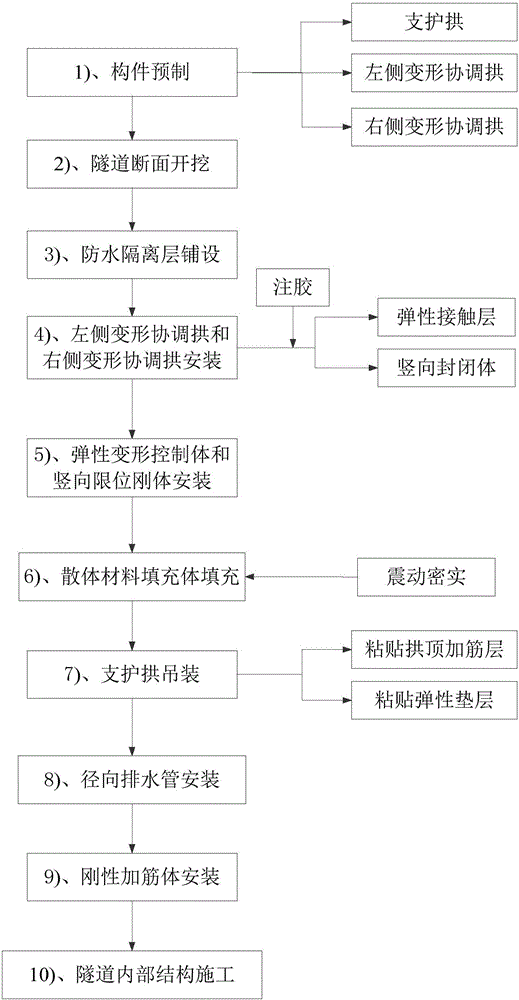

[0030] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0031] The design and construction technical requirements of the support arch, the design and construction technical requirements of the left deformation coordination arch and the right deformation coordination arch, the construction technical requirements of the bulk material filling body, the tunnel excavation construction technical requirements, etc., are not covered in this embodiment. Let’s go into details again, focusing on the embodiment of the structure of the present invention.

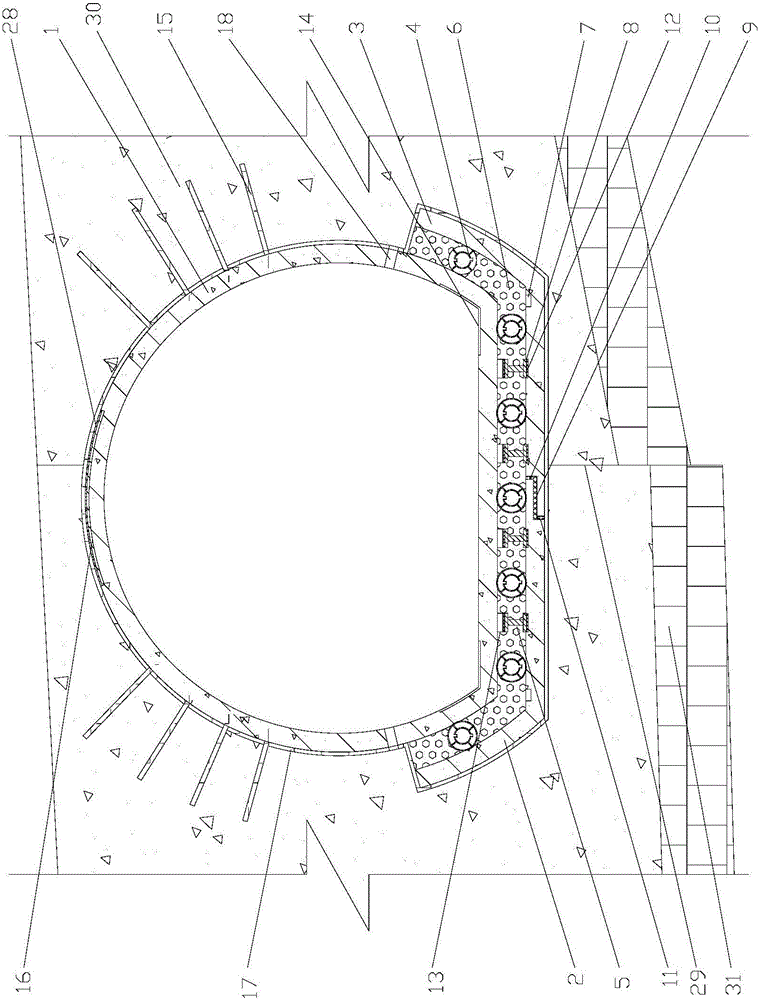

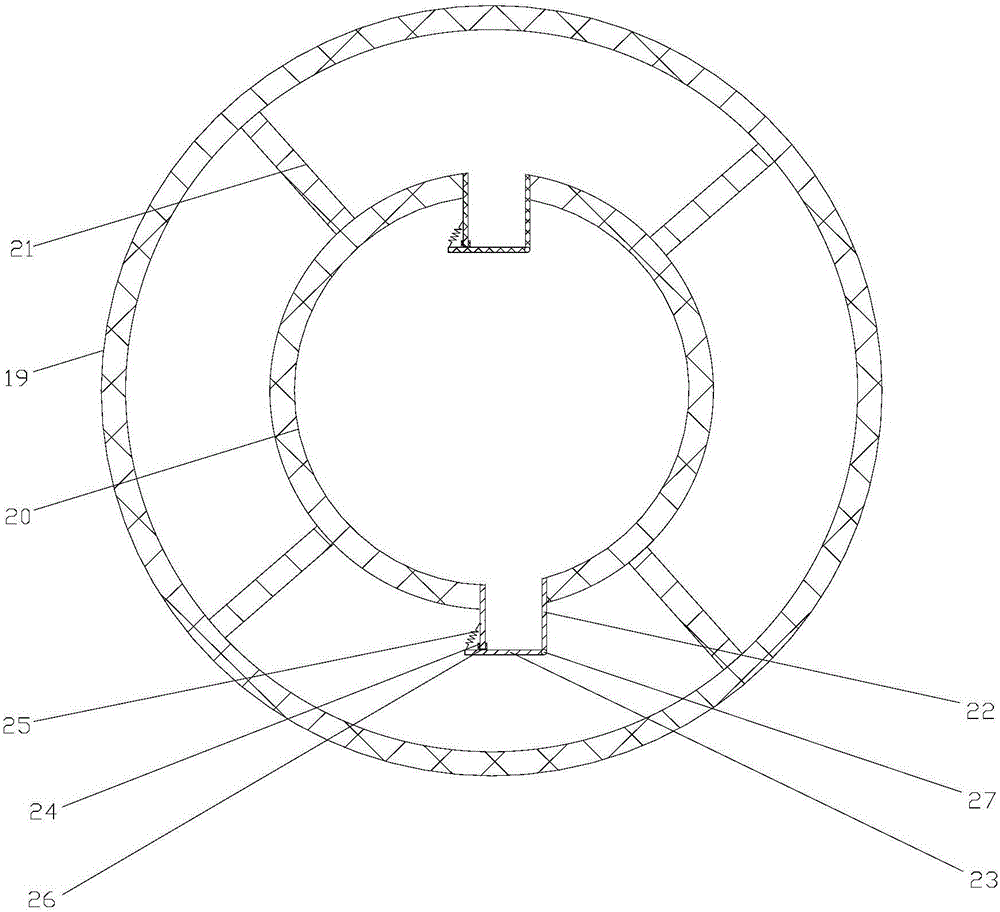

[0032] figure 1 It is a schematic diagram of a deformation-coordinated support structure for a cross-fault tunnel according to the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com