A wave device and a wave power generation device

A wave and sliding surface technology, applied in the field of fluid machinery, can solve the problem of low conversion efficiency and achieve the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

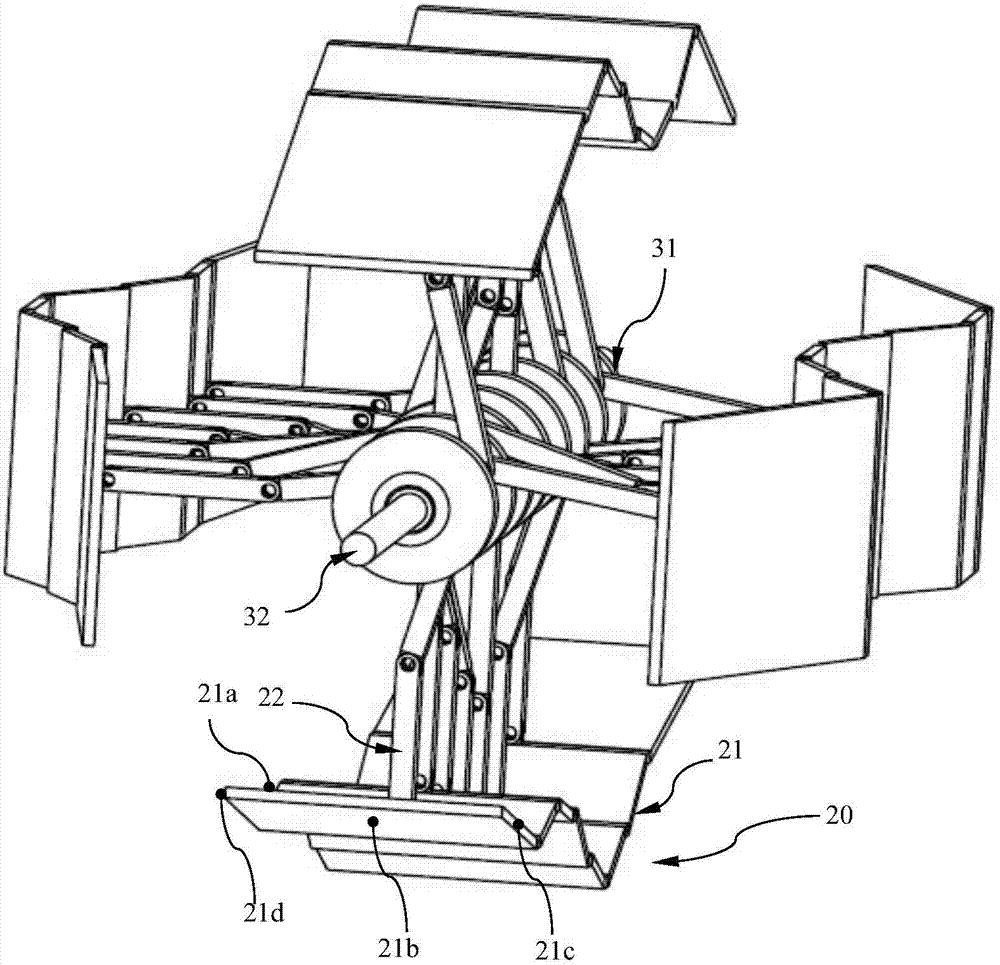

[0045] figure 1 This is a schematic structural diagram of the wave power generation device of this embodiment.

[0046] Such as figure 1 As shown, the wave power generation device 1000 includes a wave device 100 and a generator 200 (not shown in the figure). The wave device 100 transmits mechanical energy to the generator 200 through an output shaft and drives the generator 200 to run to generate electrical energy.

[0047] The wave device 100 includes a housing unit 10, four wave plate units 20 provided in the housing unit 10, and a crankshaft unit 30.

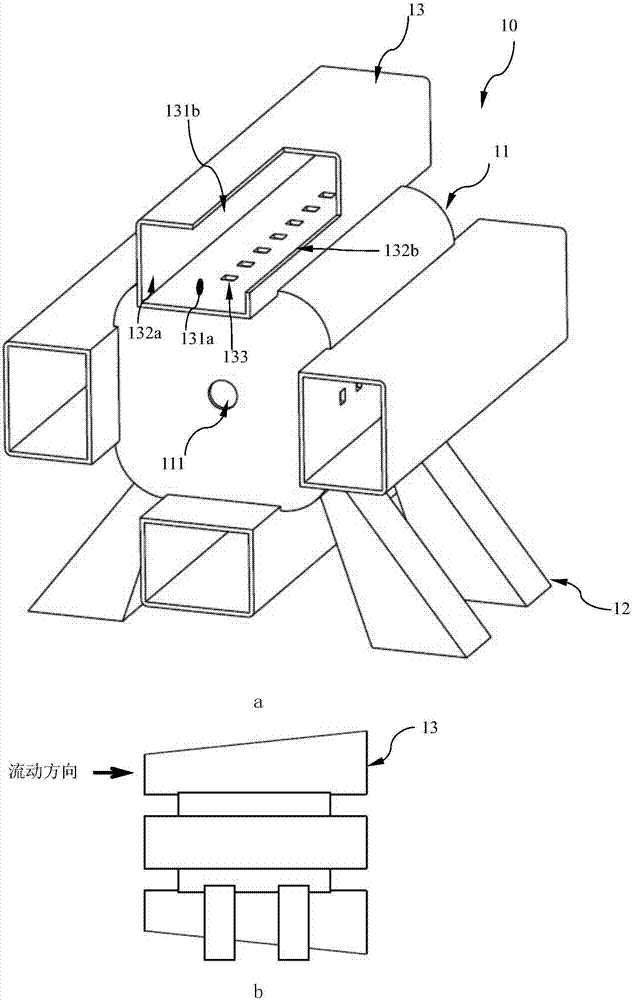

[0048] figure 2 It is a schematic diagram of the structure of the housing unit of the wave device of this embodiment, a is a schematic diagram of an isometric view, and b is a schematic diagram of a side view.

[0049] Such as figure 2 As shown, the housing unit 10 includes a cuboid-shaped housing 11, a load-bearing support composed of four load-bearing support columns 12, and four flow channels 13 arranged on the four side walls of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com