Quick connector

A fast, plug-in technology, applied in the direction of connection, parts of the connection device, coupling device, etc., can solve the problems of complex disassembly, disorder, and complicated connection, and achieve the effect of simple principle, strong implementability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

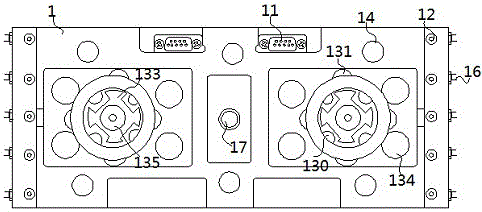

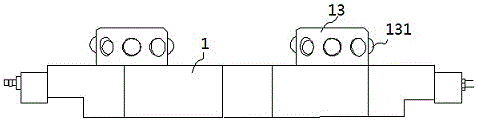

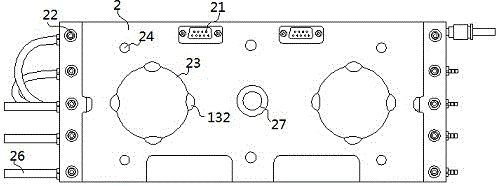

[0030] Two or more air plugs 12 are arranged at both ends of the male board 1 of the present embodiment and along the width direction of its upper end face. The male board 1 is provided with air intake pipes 16 having the same number as the air plugs 12. Each air intake pipe 16 and its corresponding air plug 12 are connected, two ends of the mother board 2 and along the width direction of its upper end surface are provided with more than two air insertion holes 22, and the number of air insertion holes 22 on the mother board 2 is the same Each outlet pipe 26 is connected with its corresponding air socket 22. The number of air sockets 22 and air plugs 12 are the same and one-to-one correspondence. The operator can adjust the air inlet pipes in different positions according to the needs of use 16 to realize the control of the gas passage of the corresponding outlet pipe 26 on the motherboard 2, and finally realize the use of suction cups at different positions on the fixture.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com