lng filling system, bog handling system and mobile lng filling ship

A filling system and processing system technology, which is applied in the field of ship filling, can solve the problems of reducing ship shipping efficiency, and achieve the effect of reducing energy consumption and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

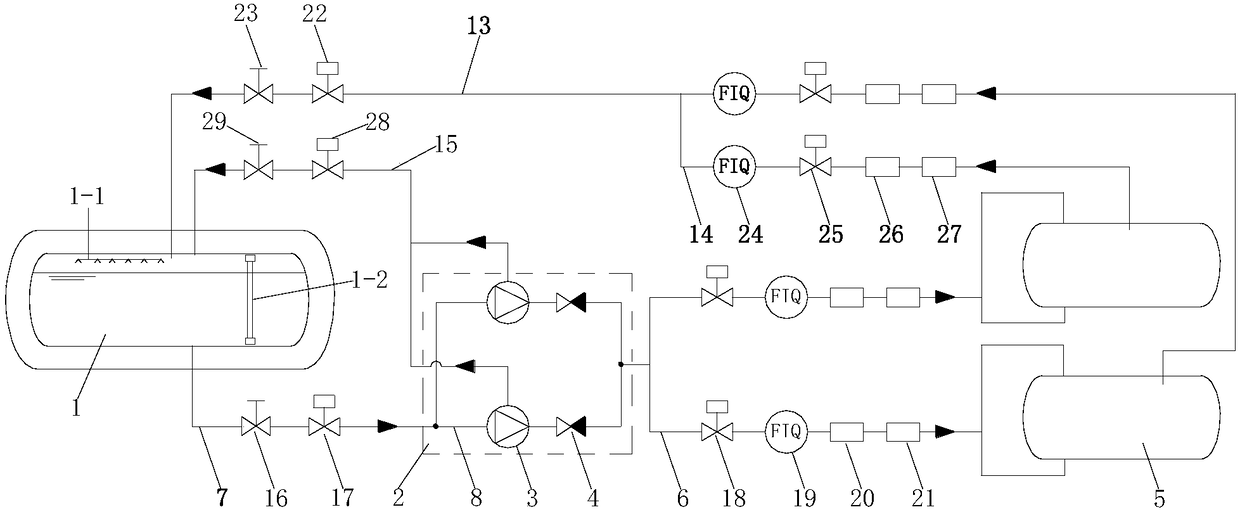

[0053] Embodiment 1: as figure 1 As shown, the present invention provides an LNG filling system, comprising a liquid cargo tank 1, a cryogenic pump group 2, a filling pipeline 6 and a gas return pipeline; the liquid cargo tank 1 is provided with a liquid injection port and a gas return port, and the liquid cargo The liquid injection port of the tank 1 is connected to the cryopump group 2 through the first pipeline 7, and the cryopump group 2 is connected to the liquid injection port of the LNG fuel tank 5 of the receiving ship through the filling pipeline 6 (the filling pipeline 6 can be One or more, each filling pipeline 6 is connected to an LNG fuel tank 5, including 2 filling pipelines in the present embodiment), the gas return end of the cryopump group 2 and the gas return port of the LNG fuel tank 5 pass through The gas return line is connected to the gas return port of the liquid cargo tank 1 to form a circulation path; the liquid cargo tank 1 can simultaneously refill t...

Embodiment 2

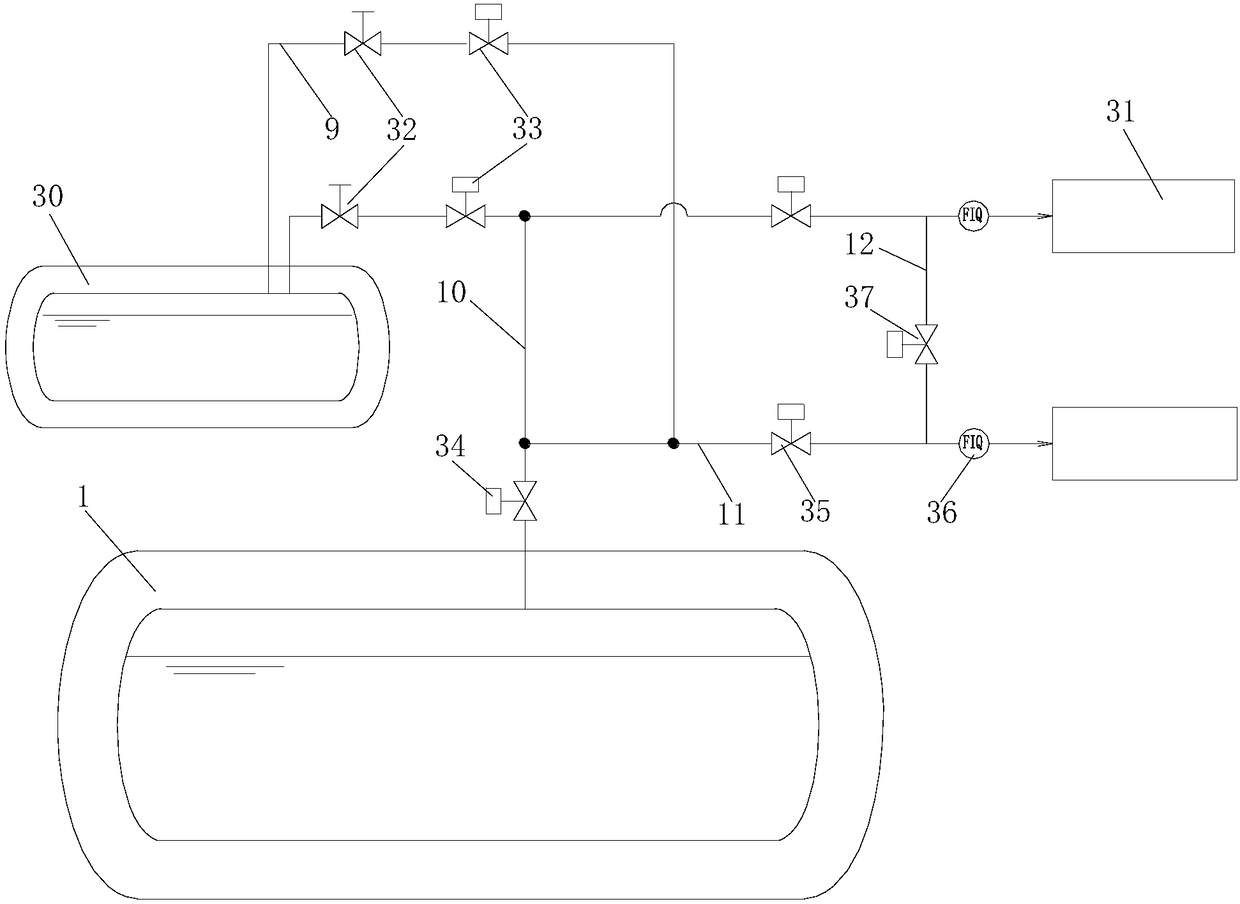

[0057] Embodiment 2: as figure 2 As shown, the present invention provides a BOG processing system, the pipeline design between the liquid cargo tank 1, the daily fuel tank 30, and the gas engine 31 can realize the hierarchical correlation processing of BOG, and realize the zero discharge of BOG; it includes Liquid cargo tank 1, daily fuel tank 30 and two gas engines 31;

[0058] The air return port of the daily fuel tank 30 is connected with two parallel third pipelines 9, the air return port of the liquid cargo tank 1 is connected with a fourth pipeline 10, and each gas engine 31 is connected with a fifth pipeline 11; Two third pipelines 9 are connected to the fourth pipeline 10, and each third pipeline 9 is connected to a fifth pipeline 11, and the fourth pipeline 10 is connected to two fifth pipelines 11 Pass; between the two fifth pipelines 11 there is a sixth pipeline 12 for communicating with the two fifth pipelines 11 . Each third pipeline 9 is provided with a gas ph...

Embodiment 3

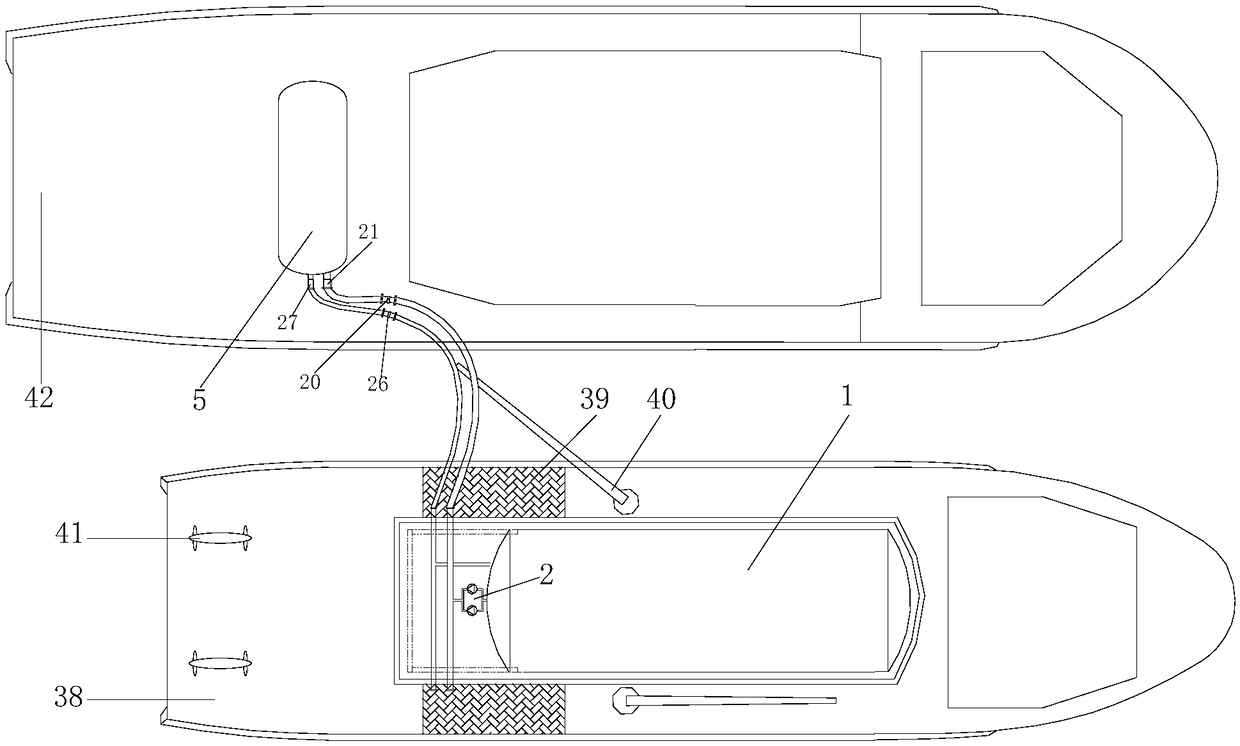

[0061] Embodiment 3: as Figure 3-4 As shown, the present invention provides a mobile LNG bunkering ship, including a hull 38, an LNG bunkering system and a BOG processing system;

[0062] The LNG filling system and BOG processing system are arranged on the hull 38, and the hull 38 on the left and right sides of the liquid cargo tank 1 is provided with a filling platform 39 and a hose crane 40, and the hose crane 40 is used to lift the filling pipeline 6 and the gas return pipeline, the cryogenic pump unit 2 is connected to the liquid cargo tank 1 and the filling pipeline to realize the transfer of LNG; the gas return pipeline is set to realize the LNG fuel of the liquid cargo tank 1 of the mobile LNG bunkering ship and the receiving ship 42 Tank 5's BOG returns gas. The first emergency break-off valve 20 and the second emergency break-off valve 26 are installed on the filling pipeline and the return air pipeline to realize the emergency break-off of the filling pipeline and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com