A corner sealing member and a sealing method using the sealing member

A sealing part and corner technology, applied in the field of LED lights, can solve the problems of not fully sticking, the shading tape is crushed, the appearance is not beautiful, and the effect of avoiding damage is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

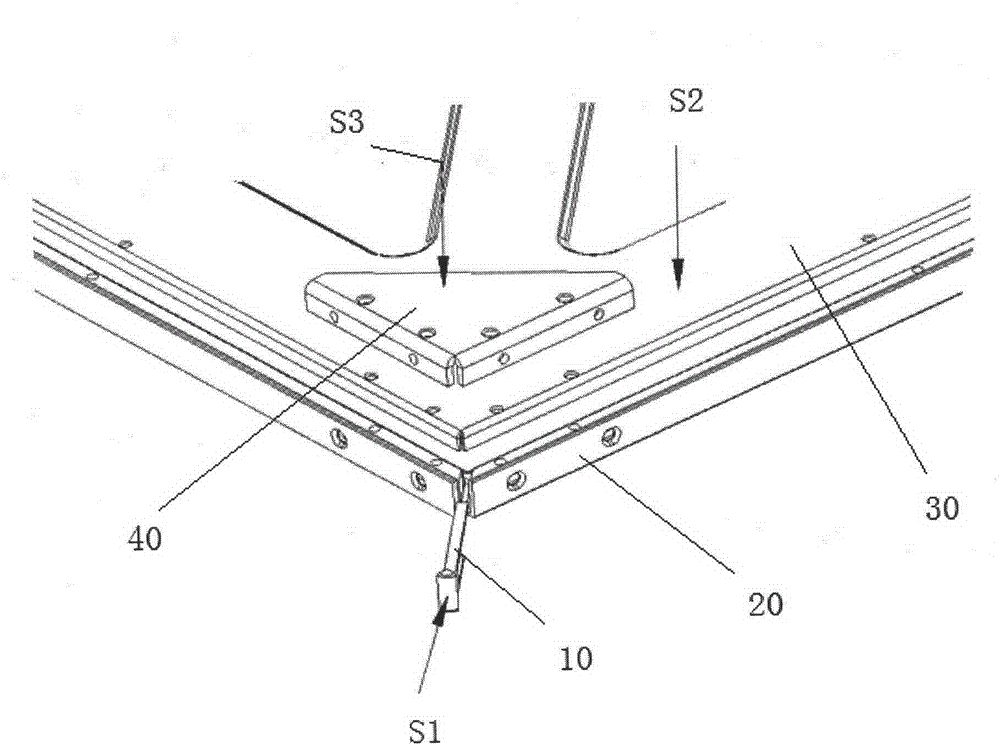

[0032] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

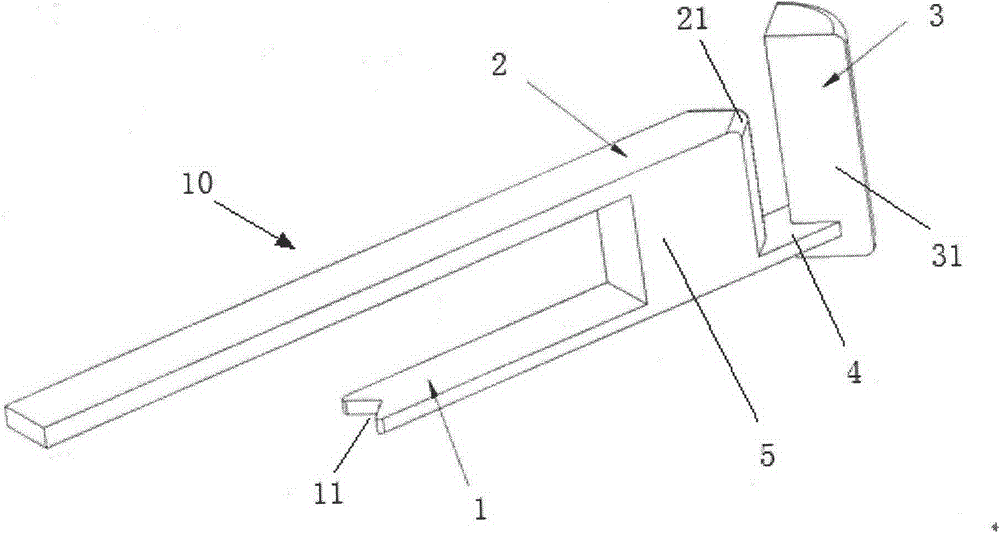

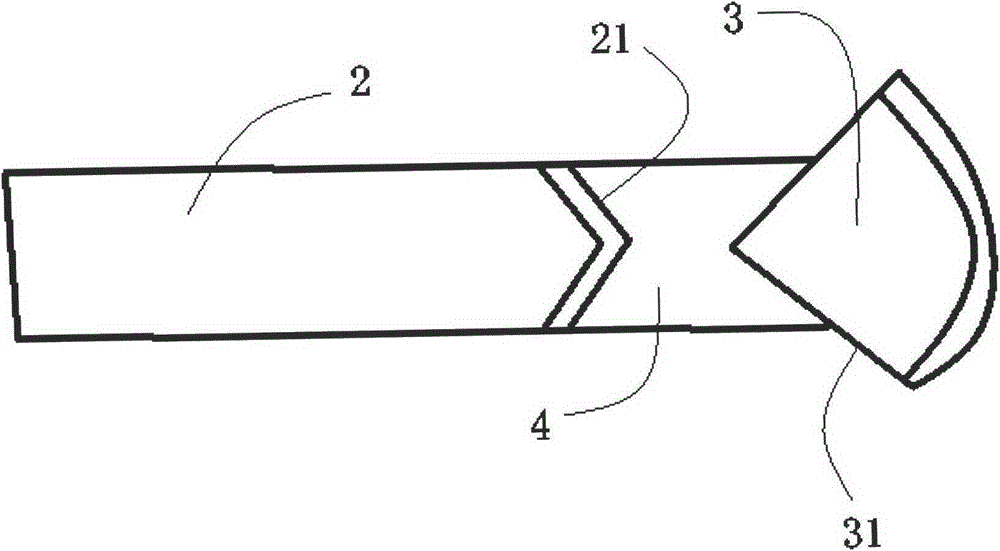

[0033] Such as figure 1 and figure 2 As shown, a corner seal 10 is used to seal the LED flat panel lamp to prevent light leakage. It includes:

[0034] The first slat 1, the first slat 1 is used to prevent light leakage from the seam. The first slat 1 is provided with a triangular groove 11 at the other end away from the first connecting member 5 , the setting of the triangular groove 11 is convenient for fixing and makes the corner seal 10 more stable.

[0035] The second slat 2 , the second slat 2 is arranged parallel to the first slat 1 , and the length of the second slat 2 is longer than that of the first slat 1 . The second slat 2 is mainly used for positioning, so that the entire corner seal 10 can be positioned more stably. .

[0036] The first connecting piece 5, the first connecting piece 5 connects the first slat 1 and the second sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com