Tensile clamp for self-lubricating wedge jaw testing machine

A wedge-shaped pliers and testing machine technology, applied in the field of testing machines, can solve problems such as poor sliding, shortened life, change in the coaxiality of jaws, etc. The effect of the eccentricity of the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

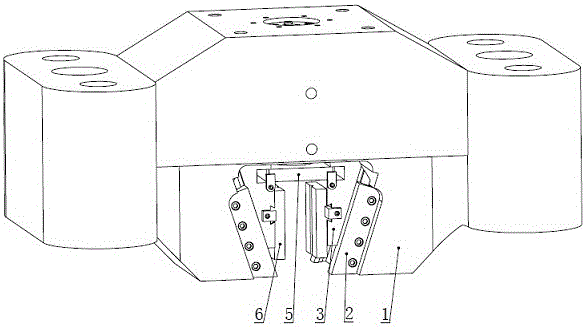

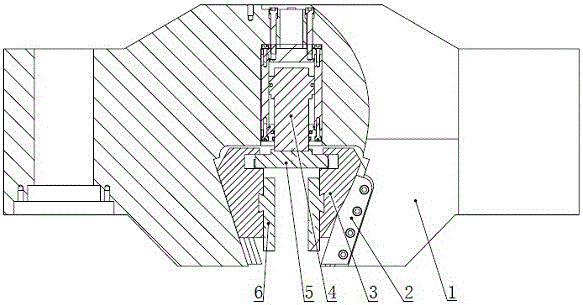

[0032] refer to Figure 1 to Figure 4 , a self-lubricating wedge-shaped jaw testing machine tensile fixture, including a clamping seat 1, a hydraulic cylinder 4, a jaw baffle 2, a slider 3, a power drive plate 5 and a clamping block 6, and the clamping seat 1 and the test The movable beam or the upper beam of the machine is an integrated structure. The clamping seat 1 has a U-shaped cavity with a narrow mouth and a wide bottom. The clamping block 6 is connected with one side of the slider 3. Jaws are formed between the blocks 6, and the other side of the slider 3 matches the side wall surface of the U-shaped cavity of the clamping seat 1 and forms a pair of sliding friction surfaces. The slider 3 can be formed in the U-shaped cavity. Slide in the space formed by the side wall surface and the jaw baffle plate 2; the piston rod of the hydraulic cylinder 4 passes through the bottom of the U-shaped cavity and is connected with the power drive plate 5; The matched sides of the sid...

Embodiment 2

[0034] refer to Figure 1 to Figure 4 , a self-lubricating wedge jaw testing machine tensile fixture, including a clamping seat 1, a hydraulic cylinder 4, a jaw baffle 2, a slider 3, a power drive plate 5 and a clamping block 6, and the slider 3 and The matching side of the side wall of the U-shaped cavity of the clamping seat 1 is coated with a wear-resistant material. The wear-resistant material in this embodiment is molybdenum disulfide. The slider is coated with molybdenum disulfide film by brushing, dipping or rolling. All the other structures are the same as in Embodiment 1.

Embodiment 3

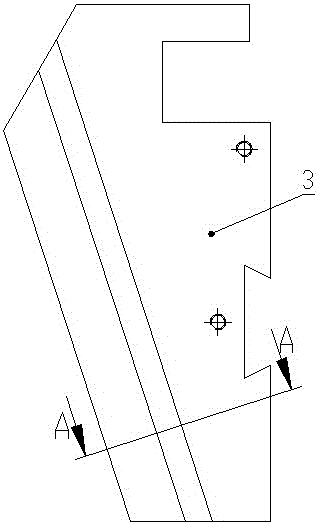

[0036] refer to Figure 5 to Figure 8, a self-lubricating wedge-shaped jaw testing machine tensile fixture, including a clamping seat 1, a hydraulic cylinder 4, a jaw baffle 2, a slider 3, a power drive plate 5, and a clamping block 6, and the clamping seat 1 has a mouth It is a U-shaped cavity with a narrower part and a wider bottom. The clamping block 6 is connected to one side of the slider 3. A jaw is formed between the two clamping blocks 6. The other side of the slider 3 is connected to the clamping block. The side wall of the U-shaped cavity of the seat is corresponding; the piston rod of the hydraulic cylinder 4 passes through the bottom of the U-shaped cavity and is connected with the power drive plate 5; the slider 3 is connected to the side wall of the U-shaped cavity of the clamping seat The corresponding side is provided with a positioning groove, and the friction plate 10 is connected to the slider 3 by bolts, so that the friction plate 10 is embedded in the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com