Skew adjustable elevator counterweight device

A technology for elevators and counterweights, applied in the field of elevators, can solve problems such as increased energy consumption of elevators, increased friction between guide shoes and guide rails, and limited operating speed, so as to improve smooth running performance, improve friction conditions, and improve coordination the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

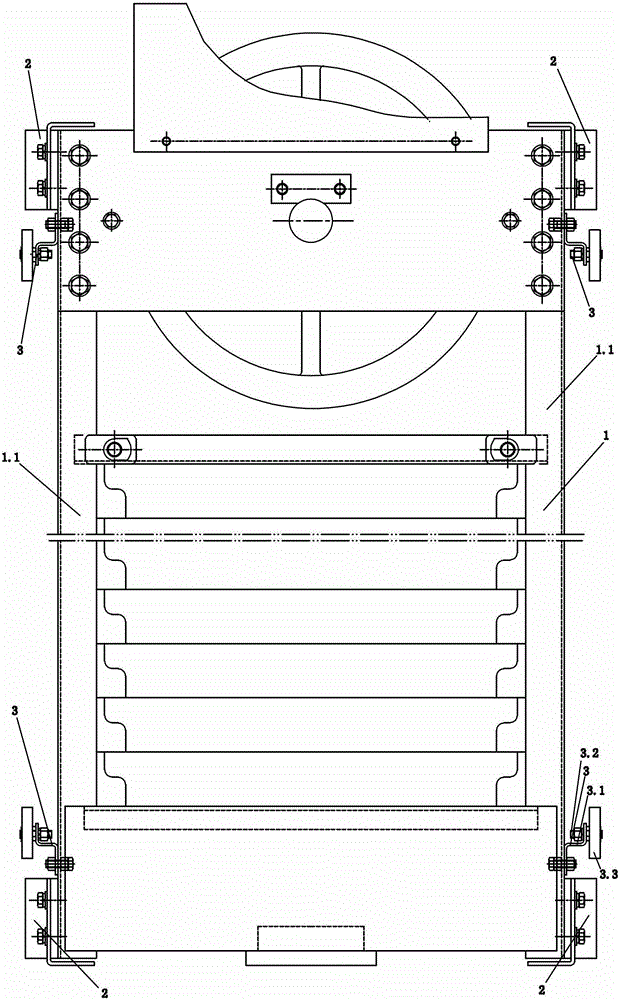

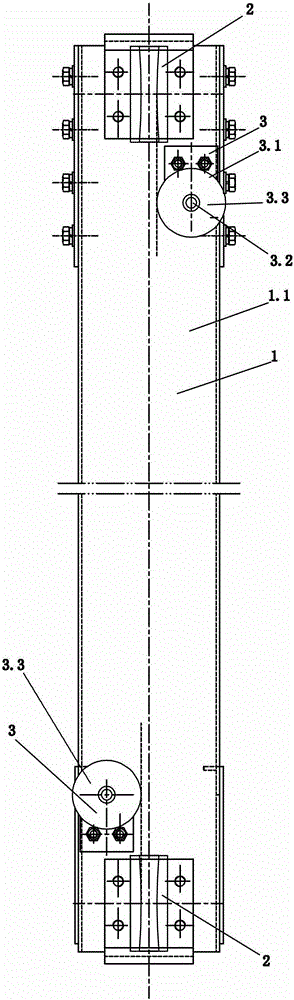

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, it includes counterweight frame 1, guide shoe 2 and four deflection adjustment components 3. The counterweight frame 1 includes two left and right counterweight frame straight beams 1.1, and four guide shoes 2 are respectively arranged on the left side or the right side of one of the upper and lower ends of the left and right counterweight frame straight beams 1.1. The two deviation adjustment assemblies 3 are divided into two groups, and the two deviation adjustment assemblies 3 of one group are arranged symmetrically on the upper end of the counterweight frame and below the corresponding guide shoes 2, and the deviation adjustment assemblies 3 of the other group are symmetrically arranged on the left and right. It is located at the lower end of the counterweight frame and above the corresponding guide shoes; the upper and lower sets of deflection adjustment assemblies 3 are misaligned fro...

Embodiment 2

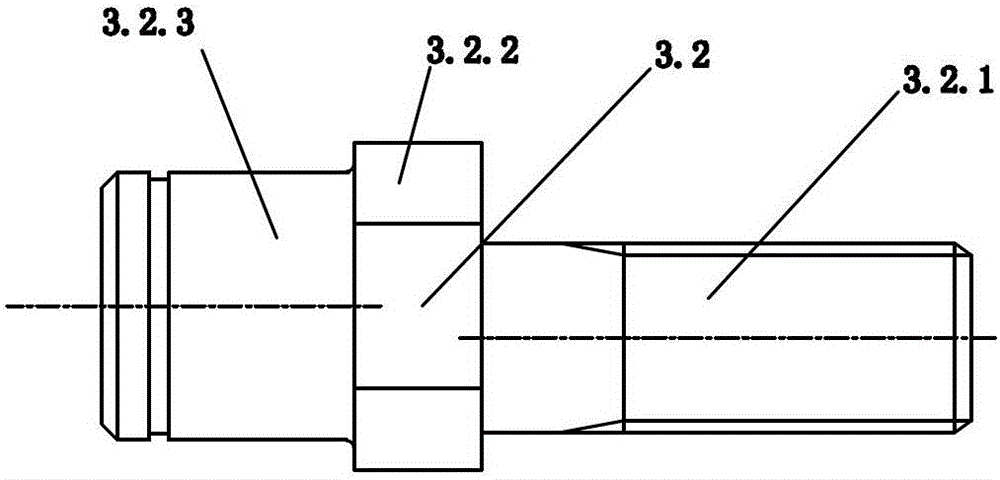

[0022] Such as Figure 6 As shown, the difference between the second embodiment and the first embodiment is that the bracket 3.1 of the deviation adjustment assembly 3 of the second embodiment is a cube-shaped part, which is fixed on the straight beam 1.1 with bolts, and is provided with a screw part 3.2. 1 Adapted screw holes, the screw part 3.2.1 is provided with fastening nuts and elastic washers, the free end of the screw part 3.2.1 is connected with the screw hole on the bracket 3.1, and the position of the eccentric shaft is adjusted with the screw part 3.2.1 The fastening nut set above is fixed at the adjusted position.

Embodiment 3

[0024] Such as Figure 7 , Figure 8 with Figure 9 As shown, the difference between the third embodiment and the first embodiment is that the bracket 3.1 of the deflection adjustment assembly 3 of the third embodiment is an L-shaped bracket. In the third embodiment, the support 3.1 of the upper group of deviation adjustment components 3 is connected to the front side of the upper beam of the counterweight frame with a bolt structure and the counterweight frame, and the support 3.1 of the lower group of deviation adjustment components 3 is connected with a bolt structure and a counterweight The frame is connected to the rear side of the lower beam of the counterweight frame, and the specific structural details of the connection are not repeated here because of the simple known technology.

[0025] The invention has simple structure and convenient use. The specific embodiments described above are only preferred implementation modes of the present invention, and are not inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com