Energy-saving high-pressure and remote constant-pressure control axial variable plunger pump

A technology of constant pressure control and variable plunger, which is applied in the direction of variable displacement pump components, pumps, multi-cylinder pumps, etc., can solve the problem of increasing maintenance costs and maintenance difficulties, affecting the working efficiency and operation of plunger pumps, and plunger pumps. Reduce the service life of the pump and other problems, and achieve the effect of increasing the service life, improving the conveying efficiency, and reducing the energy consumption of conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

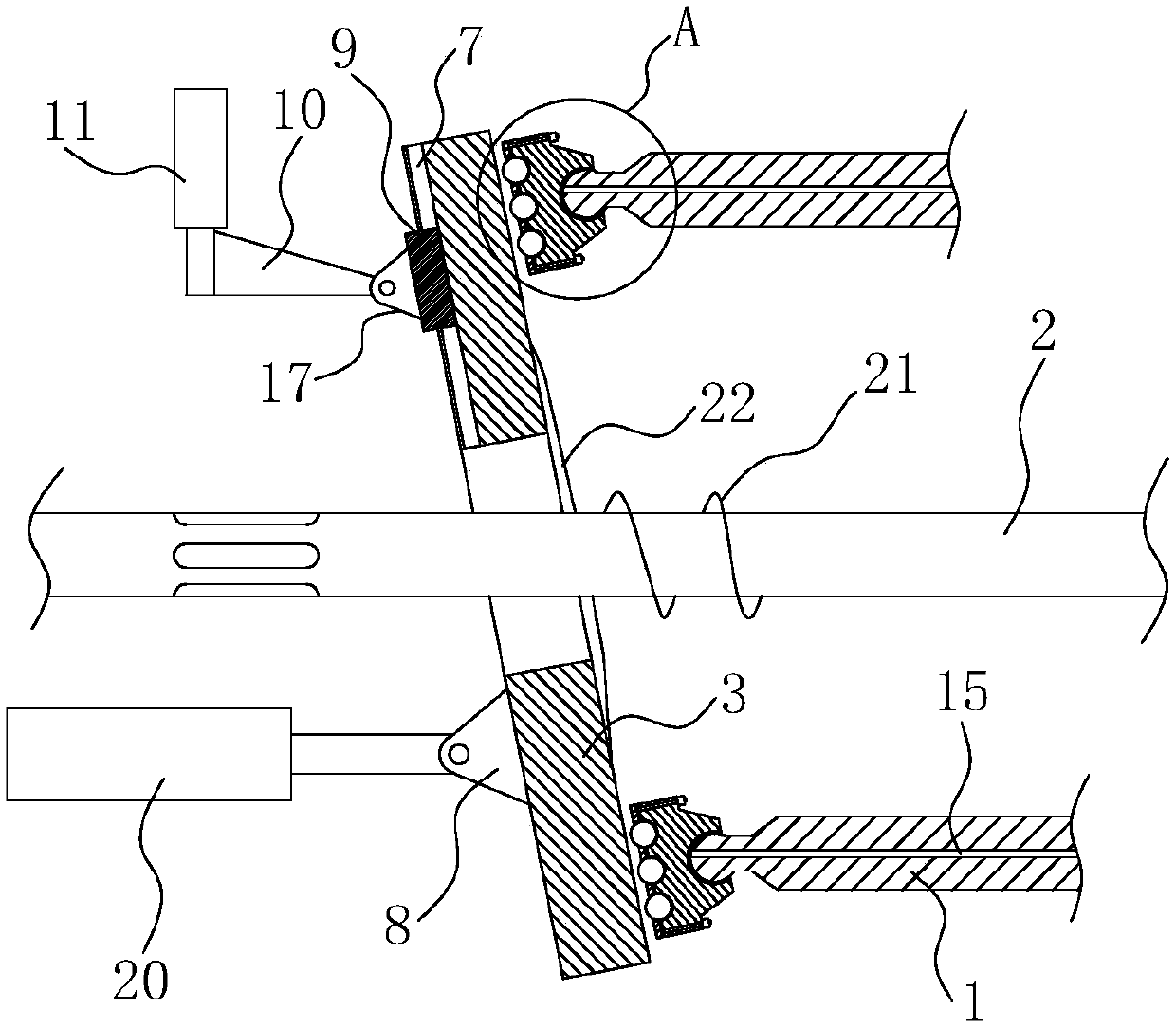

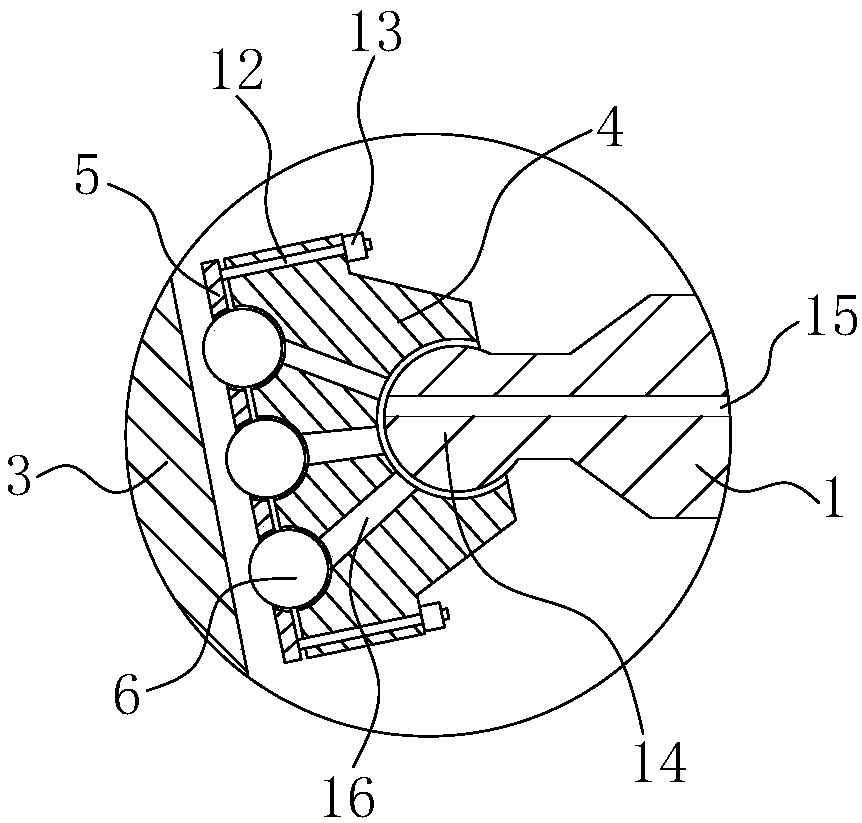

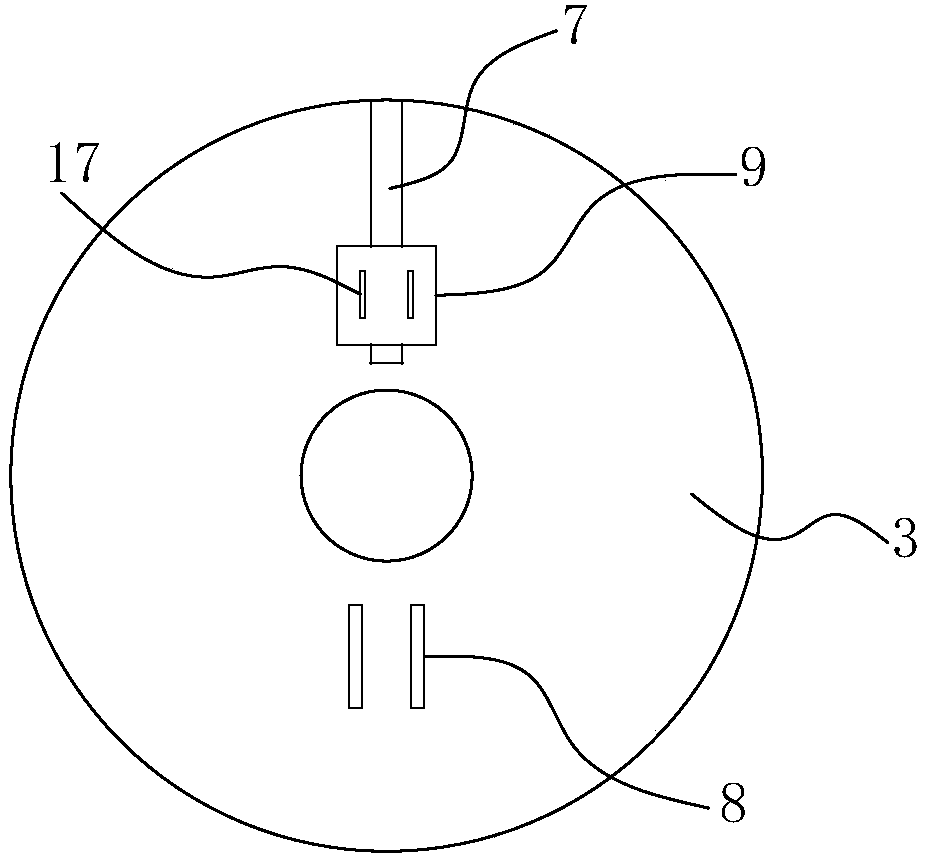

[0023] combine Figure 1-6 The shown is an energy-saving high-pressure, remote constant pressure control axial variable piston pump, including a plunger 1 and a swash plate 3 sleeved outside the transmission shaft 2; of course, the piston pump also includes a pump body, a cylinder body, a swash plate Seat, return plate, etc., due to the adoption of mature technology, there is no new improvement, so I will not repeat them here.

[0024] The transmission shaft 2 is located in the pump body, and a section of helical piece 21 is arranged on the shaft close to the swash plate 3. The swash plate 3 faces the disk surface of the plunger 1, and a deflector 22 is arranged outward along the center of the disk; The direction of rotation of the spiral piece 21 is the direction of direction in which the medium in the pump body is guided to the swash plate 3 . The extension direction of the guide vanes 21 is curved and facilitates the flow of the medium to the edge of the swash plate 3 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com