Piston ring of automobile hydraulic assistance steering device

A technology of hydraulic power steering and piston ring, which is applied to power steering mechanism, steering mechanism, fluid steering mechanism, etc., can solve the problems of power drop of hydraulic power steering system, increase of leakage of hydraulic power steering gear, wear of inner wall of oil cylinder, etc. The effect of quality improvement, low friction, and avoidance of excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Manufacturing of automotive hydraulic power steering piston rings using the following material composition:

[0028] Content name

Composition ratio (weight percent)

PTFE

65%

carbon fiber

18%

14%

Molybdenum disulfide

3%

[0029] The grain size of the polytetrafluoroethylene material mentioned in the above table is above 220 mesh, the purity is 99%, the tensile strength is 30-35Mpa, the carbon fiber is selected with a grain size of 300 mesh, the aspect ratio is about 8:1, and the purity is 99 % PAN-based carbon fiber; the particle size of graphite is 320 mesh, the particle size of molybdenum disulfide is 300 mesh, and the purity is 99%.

[0030] The above components are made into piston rings according to injection molding process steps such as batching-mixing-filling-holding pressure-cooling-demolding.

[0031] The piston ring was assembled on the hydraulic power steering gear of a certain model to carry...

Embodiment 2

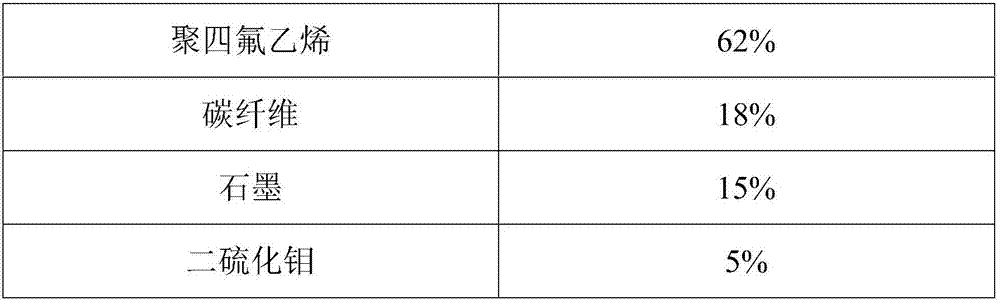

[0034] Manufacturing of automotive hydraulic power steering piston rings using the following material composition:

[0035]

[0036]

[0037] The PTFE material mentioned in the above table has a grain size above 220 mesh, a purity of 99%, a tensile strength of 20-25Mpa, and a carbon fiber with a grain size of 200 mesh, an aspect ratio of 5:1, and a purity of 99%. PAN-based carbon fiber; the particle size of graphite is 250 mesh, the particle size of molybdenum disulfide is 300 mesh, and the purity is 99%.

[0038] The above materials are made into piston rings according to the injection molding process steps such as batching-mixing-filling-pressure holding-cooling-demolding.

[0039] The piston ring was assembled on the hydraulic power steering gear of a certain model to carry out corresponding experiments, and the friction force was detected to be 115N, while the friction force of the original piston ring was about 150N. The hydraulic power steering gear was mounted on...

Embodiment 3

[0041] Manufacturing of automotive hydraulic power steering piston rings using the following material composition:

[0042] Content name

Composition ratio (weight percent)

PTFE

69%

carbon fiber

20%

graphite

10%

Molybdenum disulfide

1%

[0043] The PTFE material mentioned in the above table has a grain size above 220 mesh, a purity of 99%, a tensile strength of 25-30Mpa, and a carbon fiber with a grain size of 400 mesh, an aspect ratio of 10:1, and a purity of 99%. PAN-based carbon fiber; the particle size of graphite is 300 mesh, the particle size of molybdenum disulfide is 300 mesh, and the purity is 99%.

[0044] The above materials are made into piston rings according to the injection molding process steps such as batching-mixing-filling-pressure holding-cooling-demolding.

[0045] The corresponding experiment was carried out by assembling the piston ring on the hydraulic power steering gear of a certain model, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com