Self-calibration Method of Vertical Sensitivity of Digital Oscilloscope

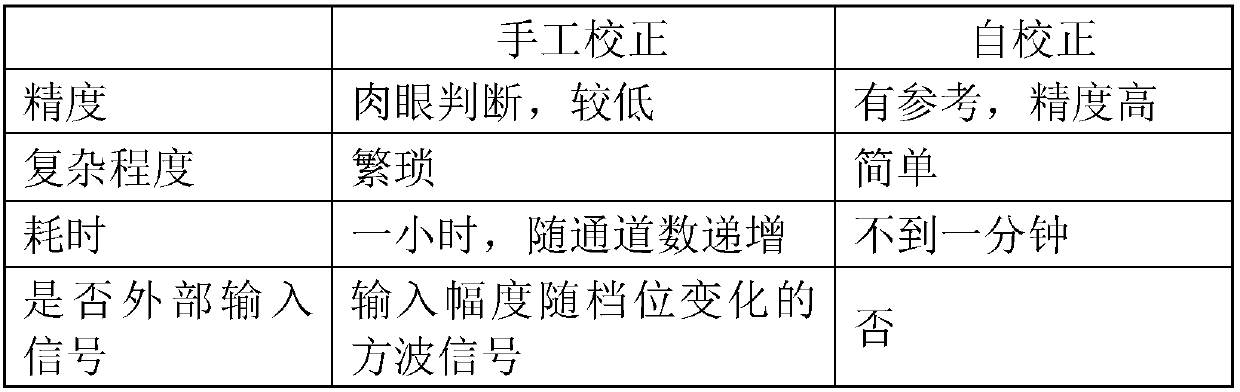

A technology of vertical sensitivity and digital oscilloscope, which is applied in the direction of digital variable display, instruments, measuring devices, etc. It can solve the problems of affecting the accuracy of components, time-consuming and laborious, and low accuracy, so as to improve the accuracy of calibration, save human resources, and improve calibration. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

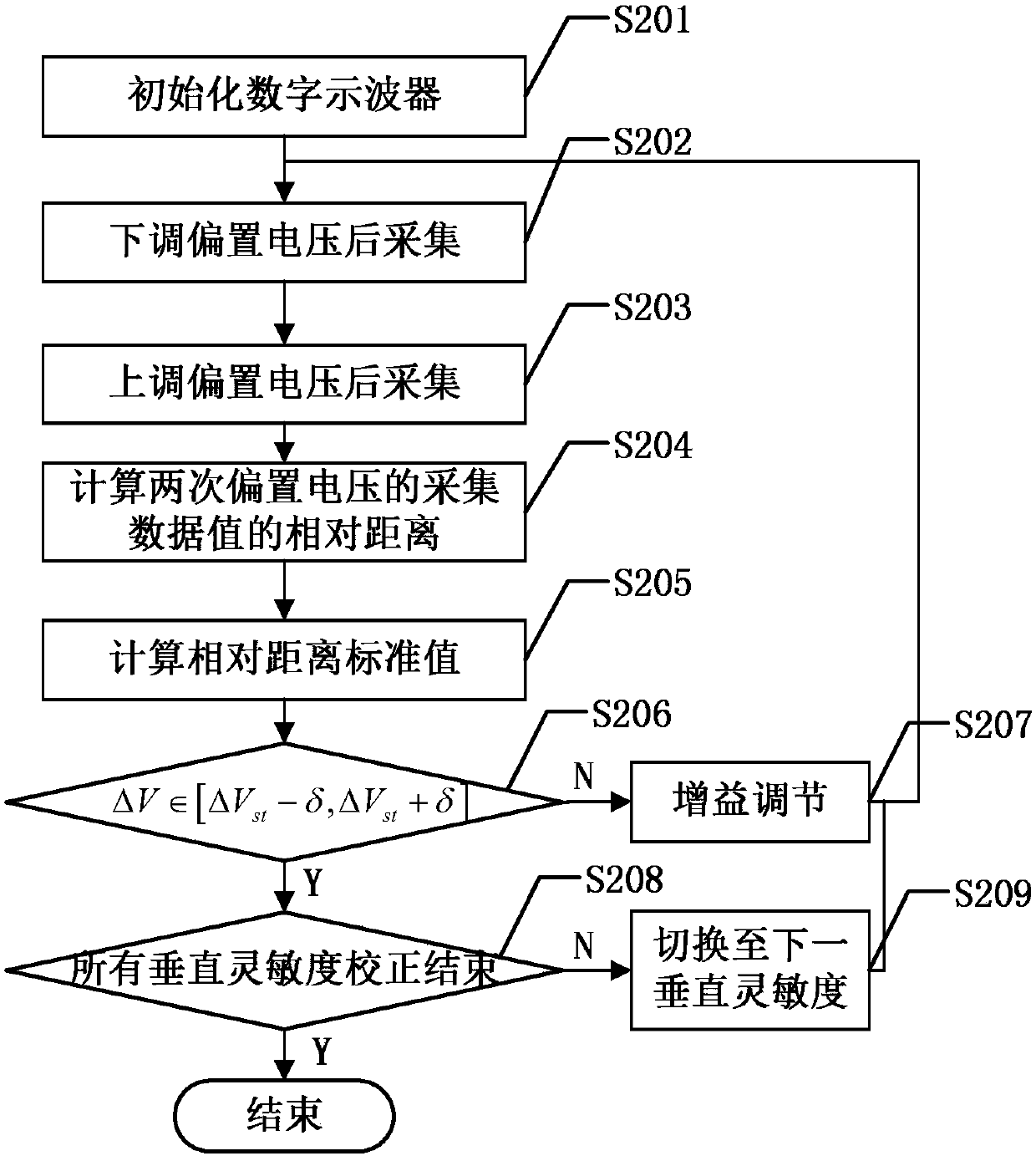

[0025] In order to better illustrate the technical solution of the present invention, firstly, a brief introduction is given to the digital oscilloscope vertical sensitivity self-calibration in the form of an example.

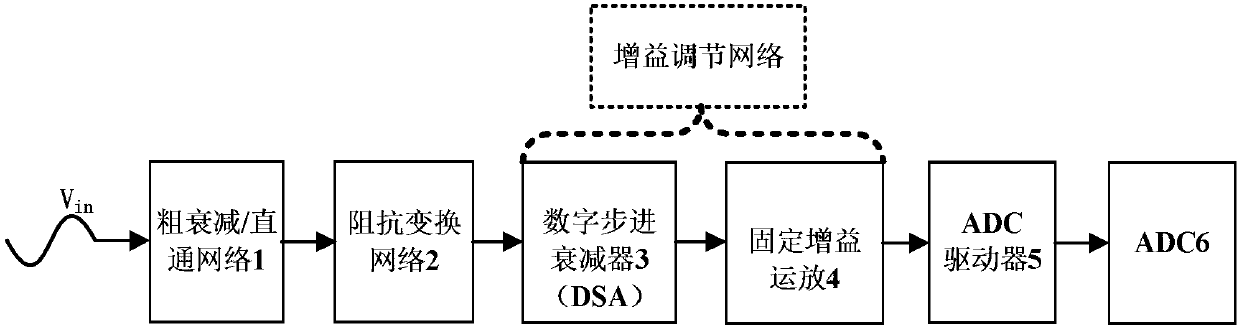

[0026] The vertical sensitivity of the digital oscilloscope refers to the voltage value (V / div) represented by the unit display length (one division) in the vertical direction. The essence of vertical sensitivity self-calibration is to correct the gain in the channel so that the amplitude value read out by the measured signal The accuracy meets the technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com