Wide-angle imaging lens

An imaging lens and wide-angle technology, applied in optical components, optics, instruments, etc., can solve the problems of expanding the field of view, unfavorable imaging quality, unfavorable lens miniaturization and light weight, etc., and achieve the effect of small size and high pixel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

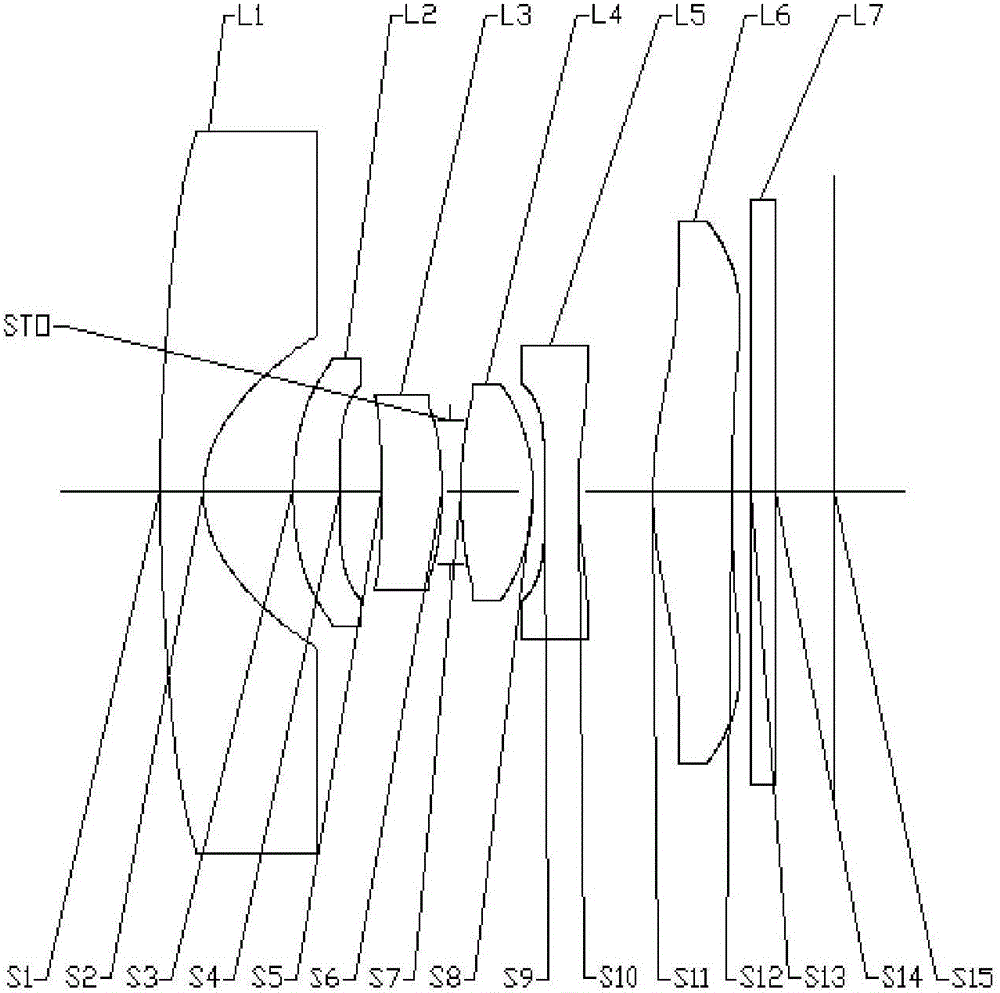

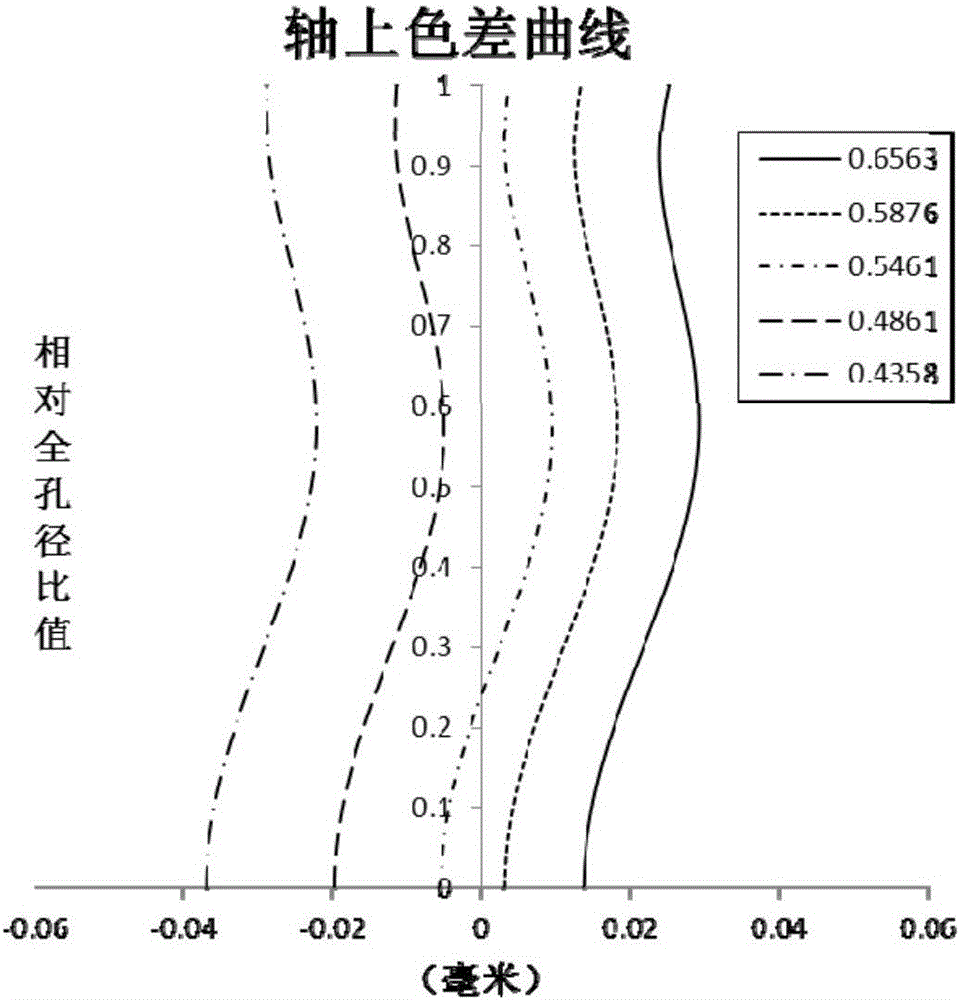

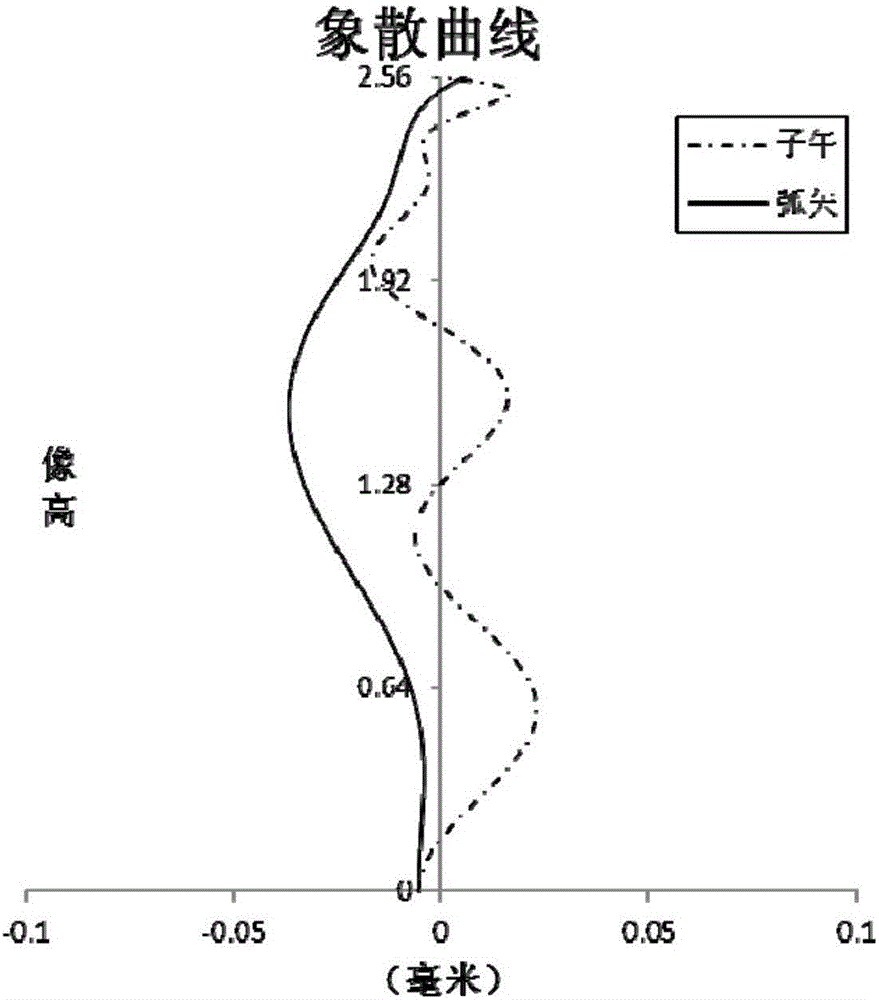

[0110] see Figure 1-4 , in Example 1, the wide-angle imaging lens satisfies the conditions of the following table:

[0111] Table 1

[0112] face number

radius of curvature

thickness

Material

Conic coefficient

OBJ

sphere

endless

endless

S1

Aspherical

10.9175

0.4000

1.535 / 55.8

0.0000

S2

Aspherical

0.8233

0.8233

-0.9126

S3

Aspherical

2.1967

0.4200

1.64 / 23.53

0.0000

S4

Aspherical

7.9063

0.3884

0.0000

S5

Aspherical

-11.8106

0.5545

1.544 / 56.11

0.0000

S6

Aspherical

-2.7549

0.0778

0.0000

STO

sphere

endless

0.0988

S7

Aspherical

3.0745

0.6612

1.544 / 56.11

0.0000

S8

Aspherical

-1.3718

0.1007

0.0000

S9

Aspherical

174.0241

0.3080

1.651 / 21.52

0.0000

S10

Aspherical

2.1813

0.6906

...

Embodiment 2

[0119] see Figure 5-8 , in Example 2, the wide-angle imaging lens satisfies the conditions of the following table:

[0120] Table 4

[0121] face number

radius of curvature

thickness

Material

Conic coefficient

OBJ

sphere

endless

endless

S1

Aspherical

7.2528

0.4000

1.535 / 55.8

0.0000

S2

sphere

0.7854

0.8540

-0.8257

S3

Aspherical

2.0040

0.4200

1.64 / 23.53

0.0000

S4

Aspherical

5.3233

0.3824

0.0000

S5

Aspherical

-31.0777

0.5481

1.544 / 56.11

0.0000

S6

Aspherical

-2.8892

0.1000

0.0000

STO

sphere

endless

0.1000

S7

Aspherical

3.2432

0.6391

1.544 / 56.11

0.0000

S8

Aspherical

-1.3653

0.1000

0.0000

S9

Aspherical

-184.2828

0.3000

1.651 / 21.52

0.0000

S10

Aspherical

2.1619

0.8613

0...

Embodiment 3

[0128] see Figure 9-12 , in Example 3, the wide-angle imaging lens satisfies the conditions of the following table:

[0129] Table 7

[0130] face number

radius of curvature

thickness

Material

Conic coefficient

OBJ

sphere

endless

endless

S1

Aspherical

6.9792

0.4000

1.535 / 55.8

0.0000

S2

Aspherical

0.8238

0.9889

-0.8916

S3

Aspherical

1.9242

0.4569

1.64 / 23.53

0.0000

S4

Aspherical

4.3484

0.4291

0.0000

S5

Aspherical

-61.3039

0.6427

1.544 / 56.11

0.0000

S6

Aspherical

-1.6420

0.0103

0.0000

STO

sphere

endless

0.0987

S7

Aspherical

-10.0140

0.6354

1.544 / 56.11

0.0000

S8

Aspherical

-1.1252

0.1043

0.0000

S9

Aspherical

40.6711

0.3350

1.64 / 23.53

0.0000

S10

Aspherical

1.9027

0.6323

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com