Hot plate air extracting device and temperature control method thereof

A technology of air extraction device and hot plate, which is applied in the direction of photosensitive material processing, etc., can solve the problems of excessive temperature fluctuation of the process chamber and unstable change of the concentration of side reactants of photoresist, etc., and achieve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

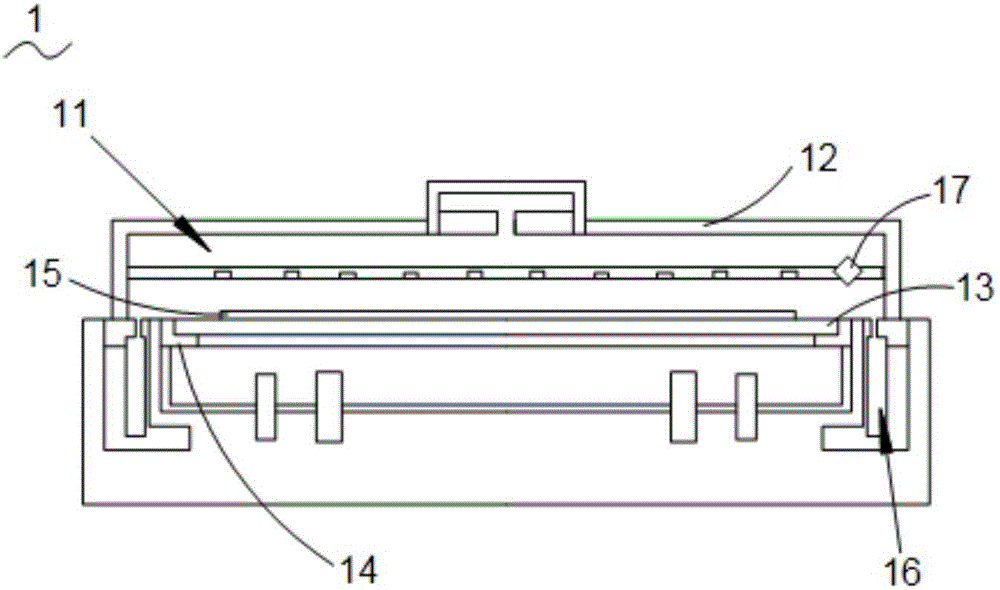

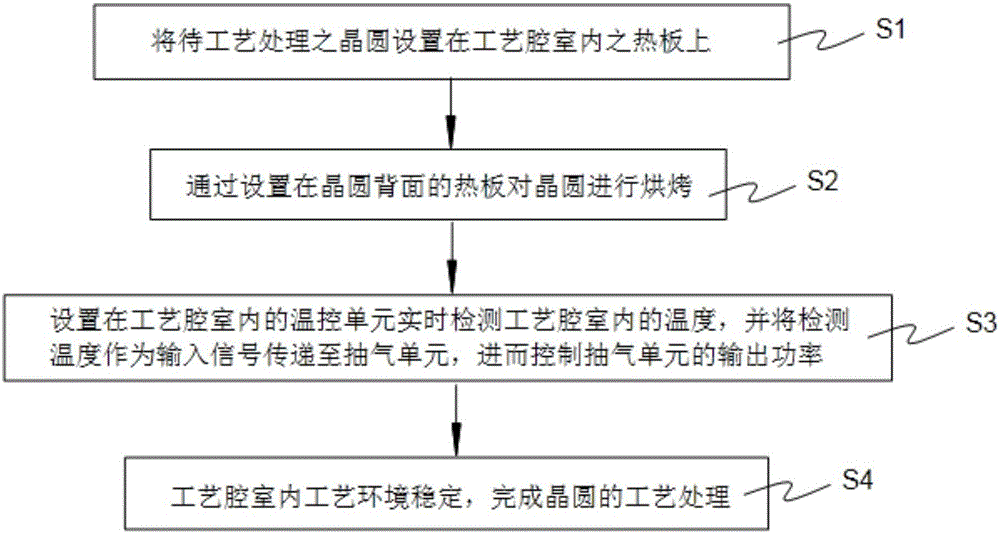

[0023] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0024] In the photolithography process of the chip manufacturing industry, the improvement of photoresist quality plays an important role in improving the process window. The baking process of photoresist is a key link in the optimization of photoresist process window. In particular, post-exposure baking (PEB) plays the most important role for chemically amplified photoresist, and the existing exposure models are equipped with chemically amplified photoresist (Chemically Amplified Photoresist, CAR), baked after coating (PAB) control also affects photoresist thickness uniformity and pattern shape. However, the temperature control of the hot plate in the prior art is limited to the temperature control on the back of the wafer. The hot pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com