An Arranged Rod Bundle Positioning Structure for Reactor Thermal-Hydraulic Experiments

A technology of thermal hydraulics and positioning structure, which is applied in the direction of reactors, reactor fuel elements, nuclear engineering, etc., can solve the problems of high cost and difficult positioning, and achieve the effect of low cost, reasonable overall structure and avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

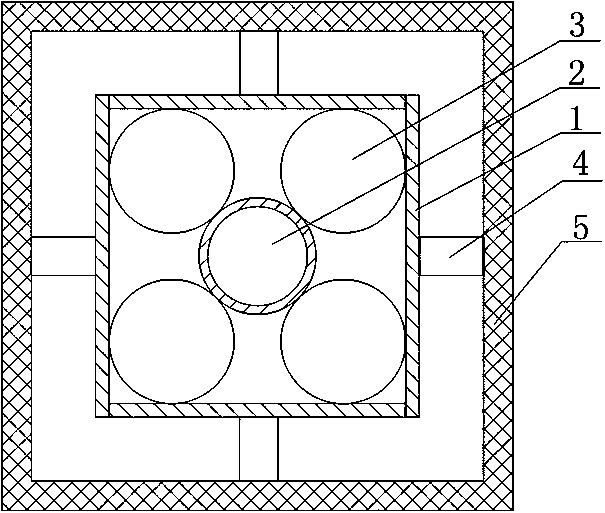

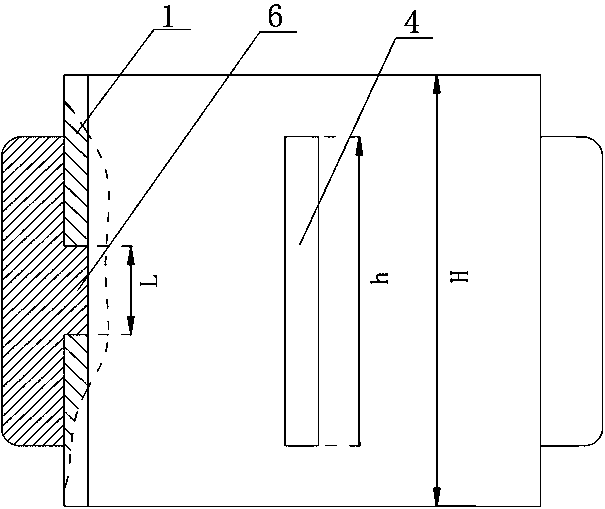

[0021] like Figures 1 to 2 The schematic diagram shown is an arrangement rod bundle positioning structure for reactor thermal hydraulic experiments, including four jacket pieces 1, a total of 4 pieces, jacket piece 1 includes a pair of long pieces and a pair of short pieces, and the short pieces are vertically welded on a pair of Between the long pieces; a rectangular socket is set in the middle of the jacket piece 1, and its height H should take into account the support strength and the influence on the flow, and should not be too small or too large, preferably between 20~40mm; To reduce the obstruction to the flow field, the sheath piece 1 is welded to form a square cavity structure, an inner fixing ring 2 is arranged on the axis of the sheath piece 1, and four heating rod bundles 3 are arranged on the inner side of the sheath piece 1, and the heating rod bundle 3. The two adjacent sheath pieces 1 are fixed tangentially to the inner fixing ring 5; the outside of the sheath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com