Method for maintaining in-situ chemical improvement effect for acidic multi-metal contaminated soil

A technology of polluted soil and soil improver, applied in the field of calcium magnesium phosphate fertilizer to maintain soil improvement effect, to achieve the effect of promoting plant growth, wide sources, simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

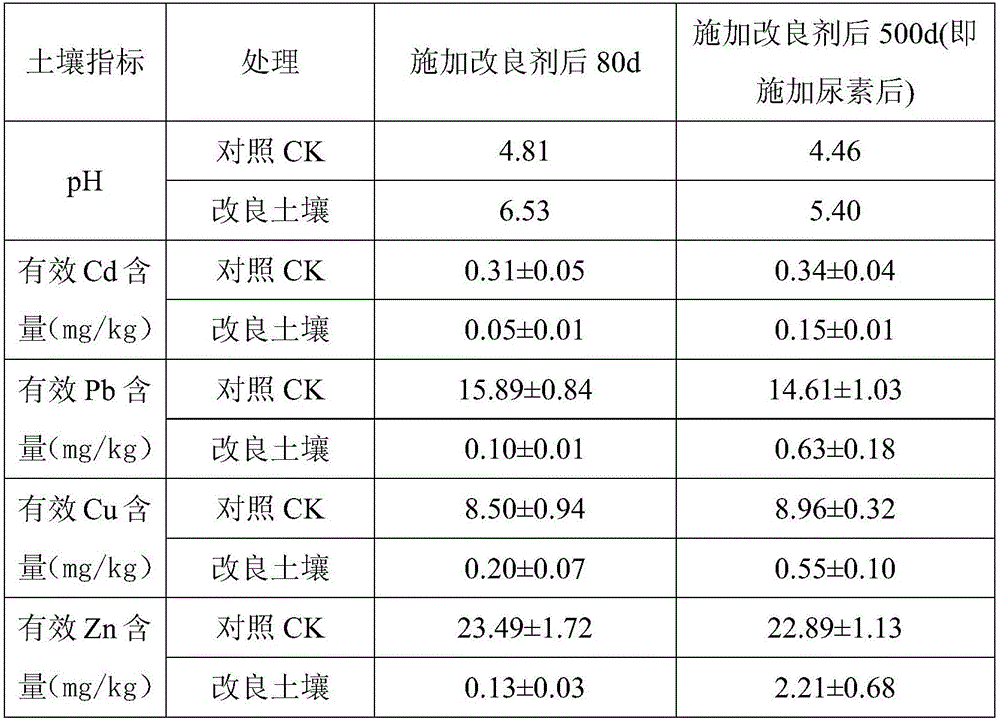

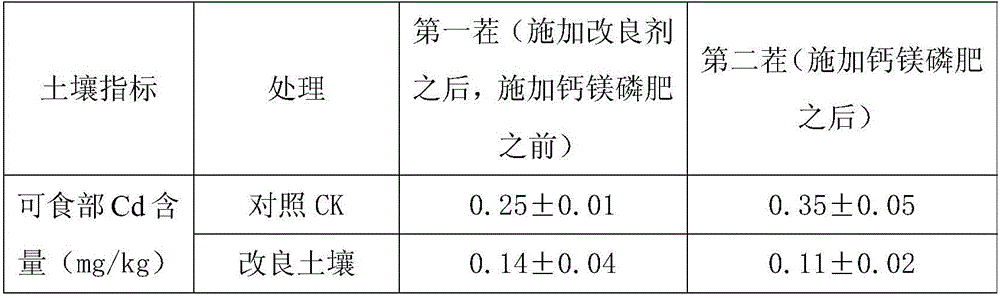

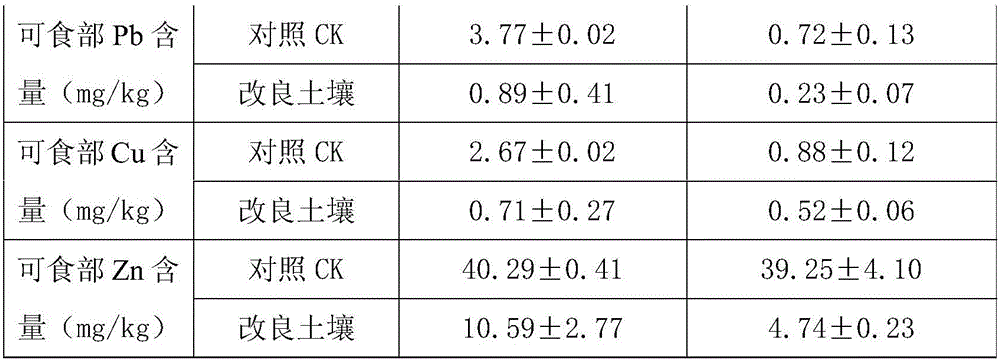

Embodiment 1

[0031] The experiment of this example was carried out in the network room of the Department of Environmental Science and Engineering, South China Agricultural University. The potting soil was taken from the 0-20cm farmland soil of Shangba Village, Xinjiang Town, Wengyuan County, Shaoguan City, Guangdong Province, in which heavy metals Pb, Cd, Cu and Zn It exceeds the national soil environmental quality standard (GB15618-1995). Put 2.8kg of soil in each pot, apply 36.4g of mixed improver, that is, the application rate is 13g / kg of soil, converted into field dosage (take soil bulk density of 1.30g / cm3, surface height of 0.15m): 1.30*0.15*667*13= 1690kg / mu. The improving agent is composed of limestone, zeolite, phosphate rock powder and mushroom slag, and the mass ratio of limestone, zeolite, phosphate rock powder and mushroom slag is 2:4:3:4. After the amendment is fully mixed with the soil, add deionized water to 60% of the field water holding capacity, fully balance at room t...

Embodiment 2

[0040] The test of this embodiment was carried out in the downstream area of the polluted waters of the Dabaoshan mining area in Shangba Village, Xinjiang Town, Wengyuan County, Shaoguan City, Guangdong Province, where the heavy metals Pb, Cd, Cu and Zn exceeded the national soil environmental quality standard (GB15618-1995). The experimental field was divided into 6 blocks, and each block was divided into 3 fields of 1m×2m, a total of 18 small fields, and the row spacing between the fields was 30cm. After the land is turned over, the gullies between the fields are dug and stacked to form 15cm thick fields. Amendment was applied on May 20, 2014 for soil improvement. Wherein the improver is provided with 3 treatments: zeolite+limestone+phosphate rock powder (handling A) (the application amount of each field is 3.51kg, i.e. application rate 1170kg / mu, wherein the mass ratio of limestone, zeolite and phosphate rock powder 2:4:3), zeolite+limestone+phosphate rock powder+mushroo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com