Magnetic core after-treatment device

A post-processing device and magnetic core technology, which is applied in the direction of spraying device, surface coating liquid device, inductor/transformer/magnet manufacturing, etc., can solve the problem of low electrode bending efficiency and achieve the effect of improving post-processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

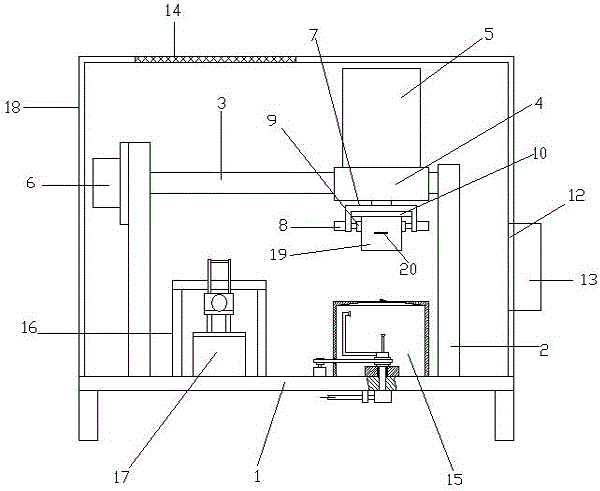

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

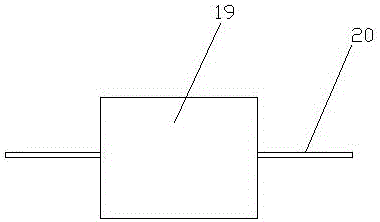

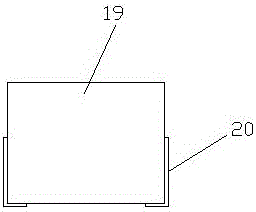

[0026] Such as image 3 and Figure 4 The shown magnetic core post-processing device includes a base plate 1, vertical support plates 2 are provided at both ends of the base plate 1, horizontal slide rails 3 are provided between the upper ends of the support plates, and sliding seats are provided on the slide rails 3 4. The upper side of the sliding seat 4 is provided with the main cylinder 5 with the shaft end facing down, and the main screw passing through the sliding seat is also provided between the support plates, and the main motor 6 that drives the main screw to rotate is provided on the support plate; the main cylinder The shaft end of the U-shaped plate is provided with a U-shaped plate 7, and both sides of the U-shaped plate 7 are provided with a horizontal clamping cylinder 8. The shaft end of the clamped cylinder is provided with a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com