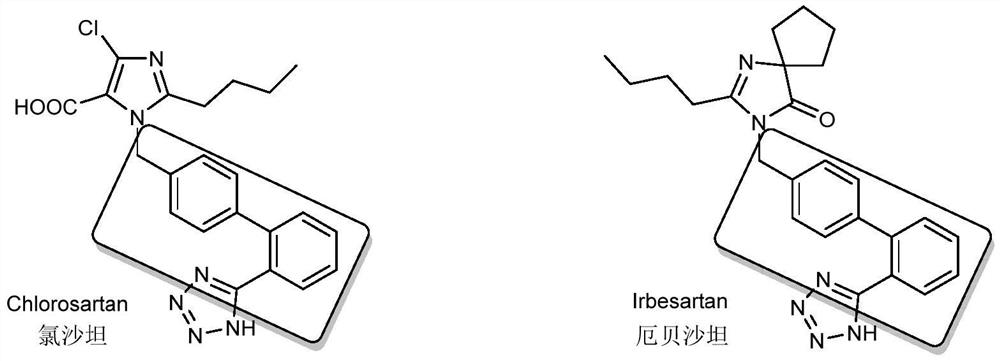

Continuous flow method for synthesizing p-bromo-methyl biphenyl carbonitrile and reaction device thereof

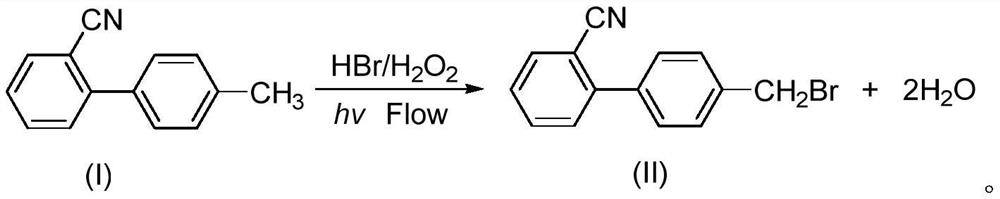

A technology of bromomethylbiphenylcyanonitrile and methylbiphenylcyanonitrile, which is applied in the field of continuous flow and reaction devices for synthesizing p-bromomethylbiphenylcyanonitrile, can solve the problem of low utilization rate of bromine atoms and the like , to achieve the effect of strong industrial application value, good safety and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

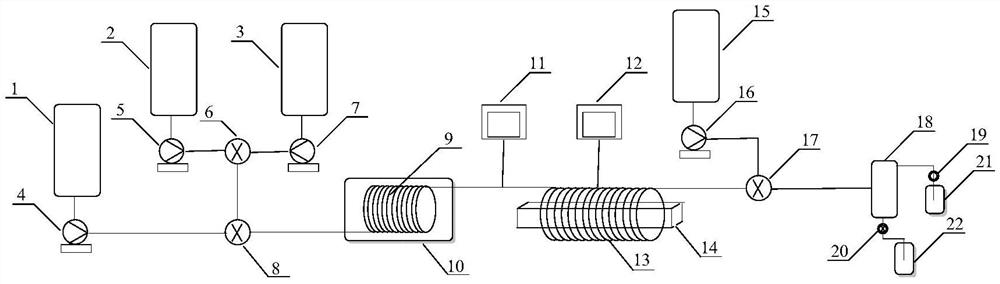

[0057] Reactor such as figure 1 shown. The length of the reactor pipe is 40m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 405nm purple LED lamp.

[0058] First open the semiconductor temperature control box 10 precooling pipelines, the temperature is set at 12 ℃, add 15% aqueous sodium carbonate solution in the quenching agent aqueous solution liquid storage tank 15; 19.3 grams (0.1mol) p-methylbiphenylcarbonitrile is dissolved in Store 200mL of dichloromethane in p-methylbiphenylcyanonitrile liquid storage tank 1, add a sufficient amount of 40% hydrobromic acid in hydrobromic acid aqueous solution liquid storage tank 2, add sufficient amount of hydrogen peroxide aqueous solution liquid storage tank 3 30% hydrogen peroxide; after opening the built-in LED light source 14, start each pump to pump the material, adjust each pump speed to make p-methylbiphenylcyanonitrile: hydrobromic acid: hydrogen peroxide mol ratio is controlled at 1:1.1:1.2, con...

Embodiment 2

[0060] Reactor such as figure 1 shown. The length of the reactor pipe is 40m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 475nm blue LED lamp.

[0061] First open the semiconductor temperature control box 10 precooling pipelines, the temperature is set at 13 ° C, add 15% aqueous sodium bicarbonate solution in the quenching agent aqueous solution liquid storage tank 15; 19.3 grams (0.1mol) p-methylbiphenylcarbonitrile is dissolved Store in 200mL ethyl acetate in p-methylbiphenyl cyanonitrile liquid storage tank 1, add sufficient amount of 40% hydrobromic acid in hydrobromic acid aqueous solution liquid storage tank 2, add sufficient amount of 30% hydrobromic acid in liquid storage tank 3 % hydrogen peroxide; After opening the built-in LED light source 14, start each pump to pump the material, adjust each pump speed to make p-methylbiphenylcyanonitrile: hydrobromic acid: hydrogen peroxide mol ratio is controlled at 1:1.2:1.4, control the reaction...

Embodiment 3

[0063] The structure of the reaction device is as figure 1 As shown, the length of the reactor pipe is 45m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 565nm yellow-green LED lamp.

[0064] First open the semiconductor temperature control box 10 pre-cooling pipelines, the temperature is set at 14 ℃, add 15% aqueous sodium carbonate solution in the quenching agent aqueous solution liquid storage tank 15; 19.3 grams (0.1mol) p-methylbiphenylcarbonitrile is dissolved in 200mL of ethyl acetate is stored in the p-methylbiphenylcyanonitrile storage tank 1, a sufficient amount of 40% hydrobromic acid is added to the hydrobromic acid aqueous solution storage tank 2, and a sufficient amount of 40% hydrobromic acid is added to the hydrogen peroxide aqueous solution storage tank 3 30% hydrogen peroxide; Open the built-in LED light source 14, start each pump to pump the material, adjust each pump speed to make p-methylbiphenylcyanonitrile: hydrobromic acid:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com