Chip screening equipment

A technology for screening equipment and chips, which is applied in sorting and other directions, can solve problems such as collisions, low efficiency, and increased number of chips, and achieve the effect of reducing damage rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

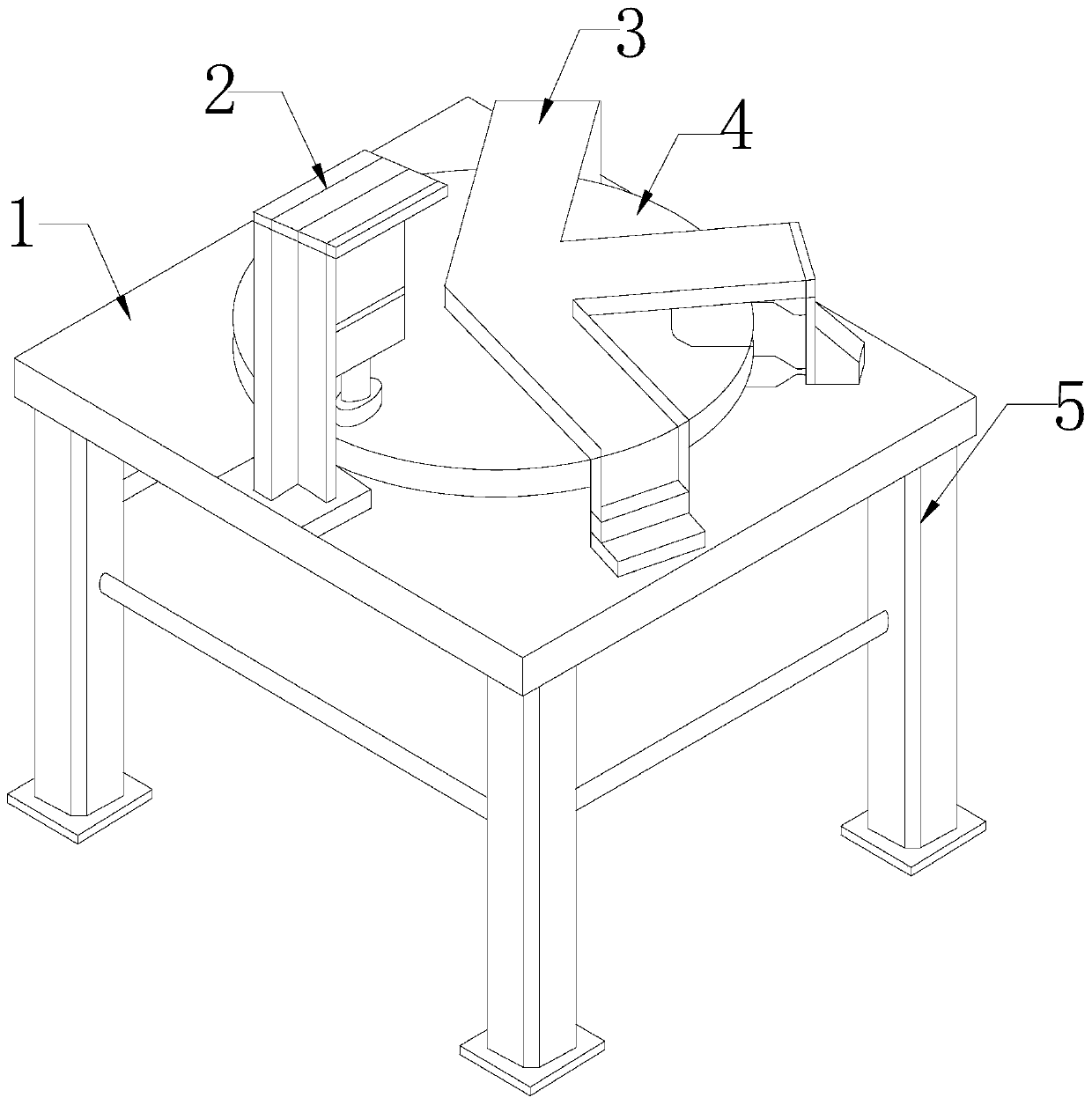

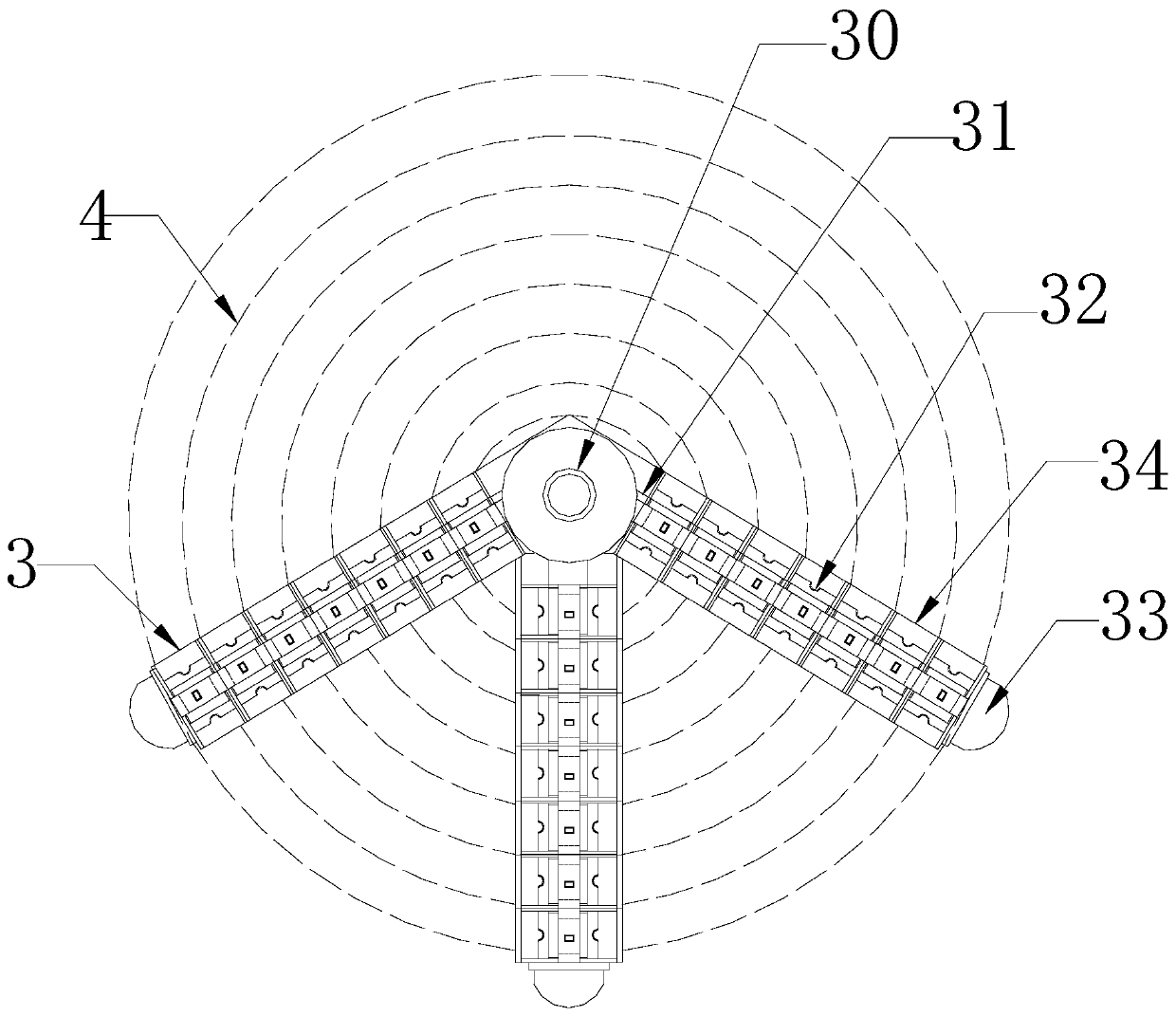

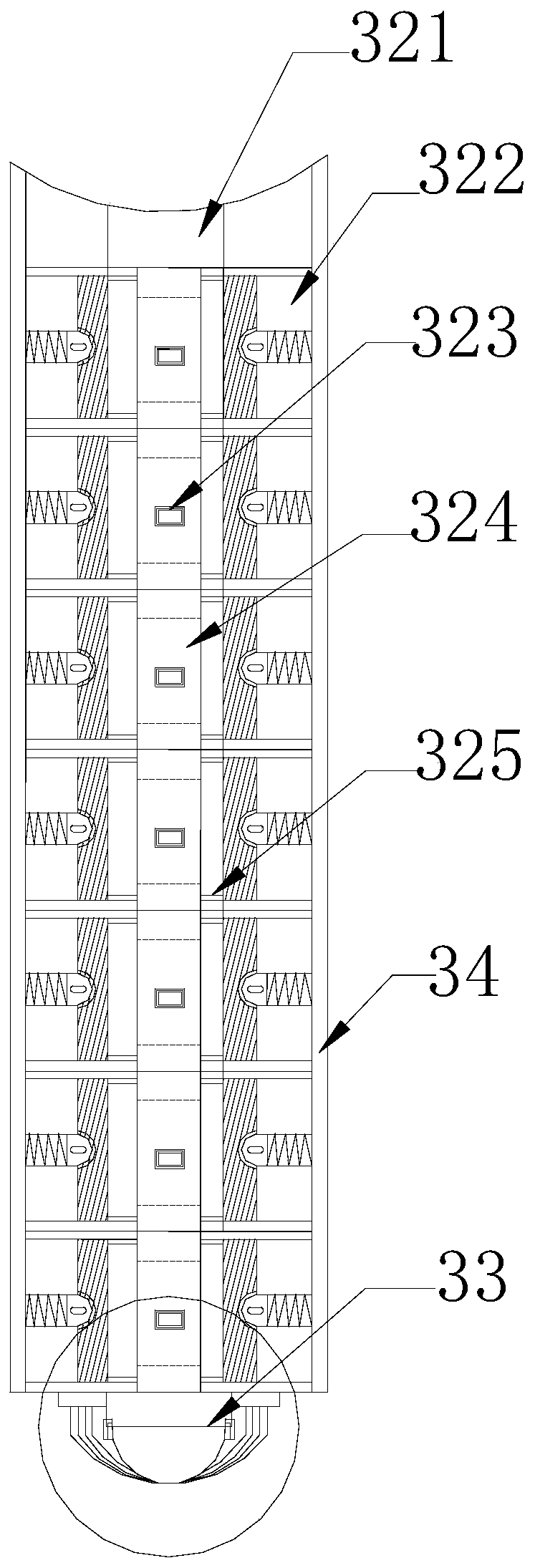

[0038] Such as Figure 1-Figure 7 As shown, the present invention provides a kind of chip screening equipment, and its structure comprises workbench 1, detection platform 2, sorting mechanism 3, test plate 4, support foot 5, and the bottom of described workbench 1 is equipped with four support feet 5, so The upper end of the workbench 1 is provided with a detection platform 2 and a test board 4. The test board 4 cooperates with the detection platform 2 and the sorting mechanism 3. The sorting mechanism 3 is a three-legged type, which can perform different levels of screening , the sorting mechanism 3 is composed of a rotating shaft 30, a push plate 31, a sorting guide 32, a transmission joint 33, and a rack 34, and the rotating shaft 30 is connected with three racks 34, and the rack 34 is horizontal More than two sorting guides 32 are installed in a straight line, and the transmission joint 33 is mechanically connected to the other end of the plate frame 34 relative to the rot...

Embodiment 2

[0048] Such as Figure 8-Figure 9 As shown, on the basis of Embodiment 1, through the mutual cooperation of the following component structures, the associated part 245 includes an outer cover 45a, an exhaust pipe 45b, a corrugated shaft 45c, a second spring 45d, and a top block 45e. The outer cover 45a Wrapped on the surface of the exhaust pipe 45b, the exhaust pipe 45b communicates with the inside of the corrugated shaft 45c, the inside of the corrugated shaft 45c is a standard atmospheric pressure, and the two ends of the second spring 45d are connected to the two ends of the corrugated shaft 45c Together, the second spring 45d is parallel to the corrugated shaft 45c, and the other end of the corrugated shaft 45c opposite to the exhaust pipe 45b is provided with a top block 45e, and the top block 45e has a semicircular structure.

[0049] The two sides of the middle suction cup 323 are equipped with connecting hinge wheels 23a and waist piece 23b, the waist piece 23b is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com