Encapsulation equipment for roof packs

A technology of packaging equipment and roof packaging, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of different heating and welding, the inability to fill nitrogen with furnace heating, and the difficulty of plane welding with high height and large area, so as to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be further described in conjunction with the embodiments and accompanying drawings. It should be understood that the embodiments are only for illustration and not intended to limit the protection scope of the present invention.

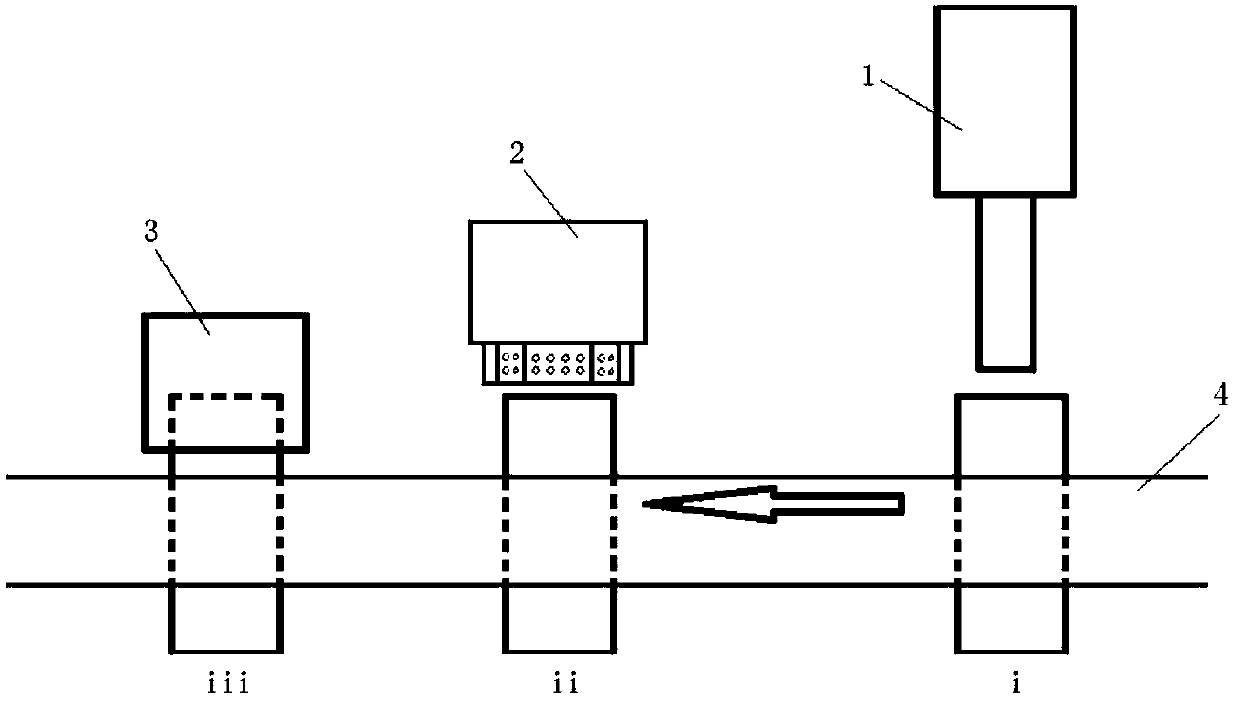

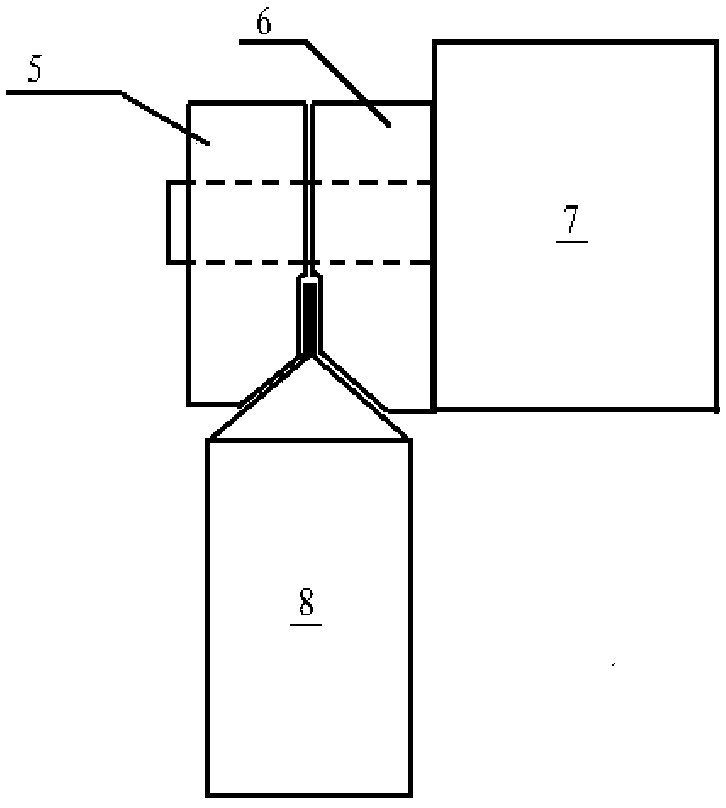

[0029] The packaging equipment structure of the roof bag of the present embodiment is as follows:

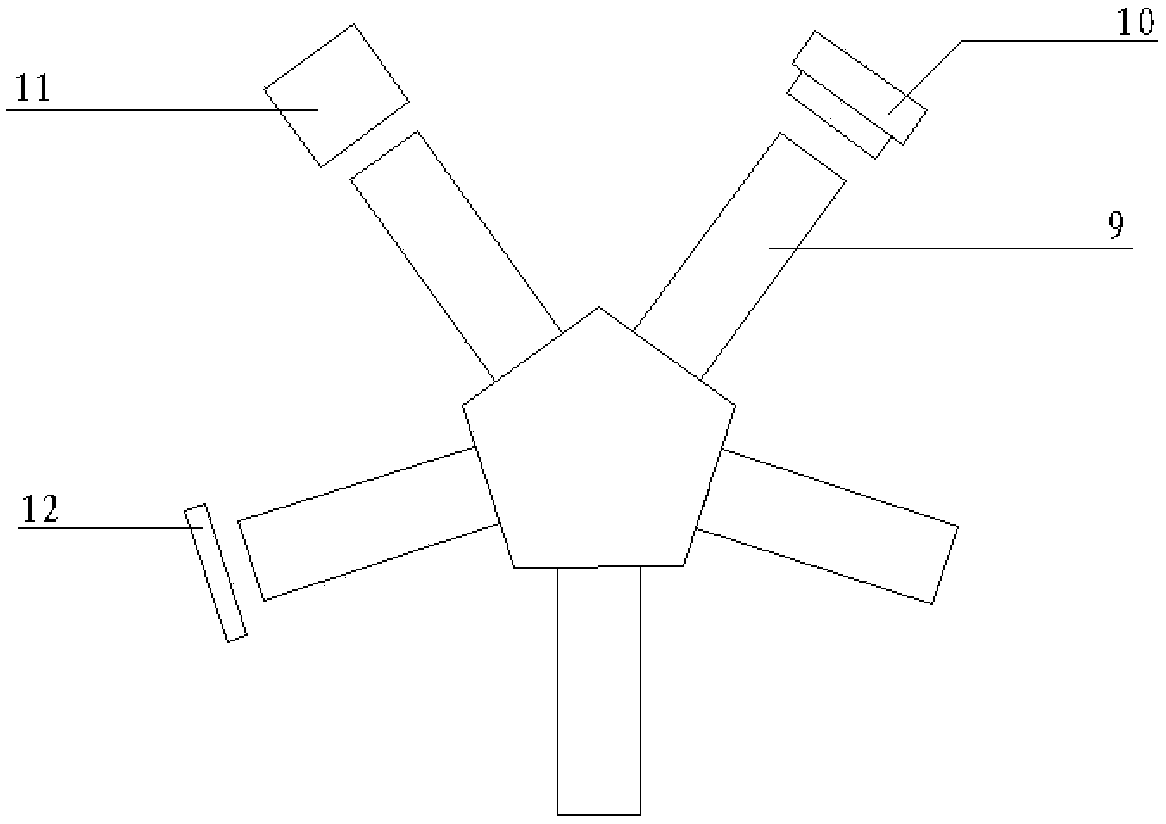

[0030] a. Figure 6 Shows the structure of the bottom packaging equipment in this embodiment, including multiple mandrels used for forming the bottom of the product, and a rotating shaft connected to drive the mandrels to rotate to multiple stations. The rotating shaft is connected to the tail end of the mandrel to make the whole shape Radiating star shape, this structure is common in bottom package devices. When the front end of the mandrel is rotating, the outer end face of the mandrel is aligned with each station. Such as folding station, heating station, etc. A plurality of stations along the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com