Oil-water replacement process for crude oil storing and discharging of single-column platform

An oil-water replacement and single-column technology, applied in the field of offshore oil engineering, can solve the problems of high investment costs, achieve the effects of avoiding pollution, reducing project investment costs, and simple operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

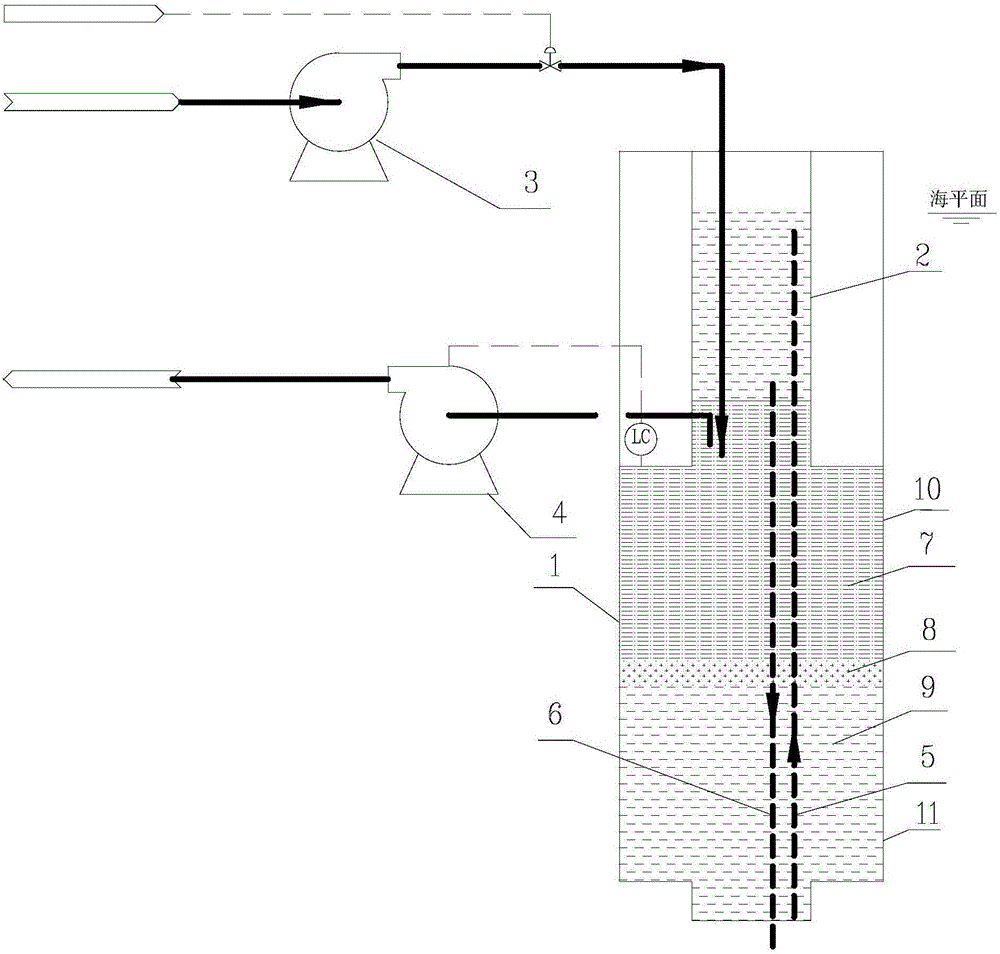

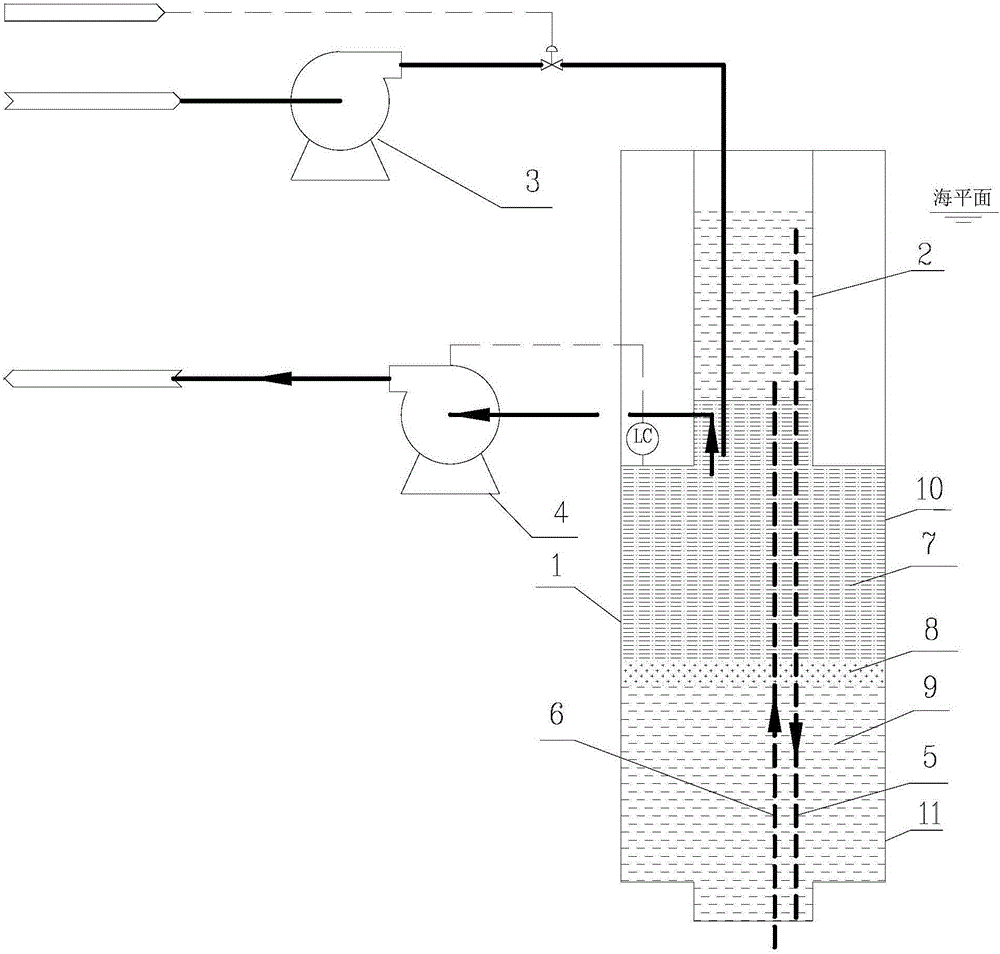

[0032] Such as figure 1 Shown, the present invention adopts following method:

[0033] 1. Fill the oil storage tank 1 and the water settlement tank 2 with water

[0034] 1. When the single-column platform is installed in place, seawater enters the water settlement chamber 2 from the outer water pipe 6 under the action of seawater static pressure;

[0035] 2. According to the principle of the connector, the oil storage tank 1 and the water settlement tank 2 are connected to the sea through the inner water pipe 5 and the outer water pipe 6. Under the action of gravity, the seawater in the water settlement tank 2 enters the oil storage tank 1 through the inner water pipe 5 ;

[0036] 3. The air in the oil storage tank 1 is discharged through the exhaust pipeline provided by the oil inlet pipeline;

[0037] 4. After the oil storage tank 1 is filled with seawater, the seawater will accumulate in the water settling tank 2, and finally, the liquid level of the water settling tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com