Remote continuous process transporting channel used for hot chamber group

A transportation channel and long-distance technology, which is applied in the field of long-distance continuous process transportation channels for hot cell groups, can solve the problems of inability to realize long-distance continuous transportation of objects, and inability to realize long-distance continuous transportation of materials, and achieve good gas Tightness, ensuring stability, ensuring independence and airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

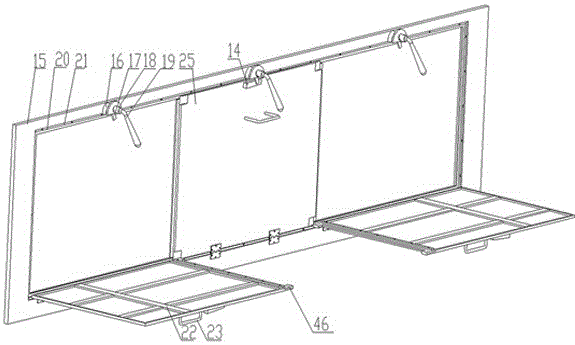

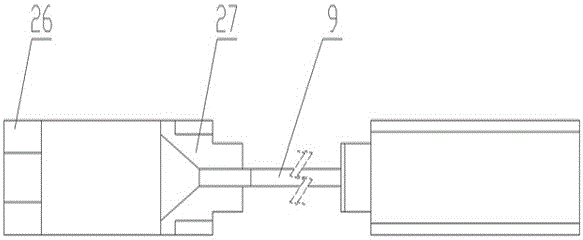

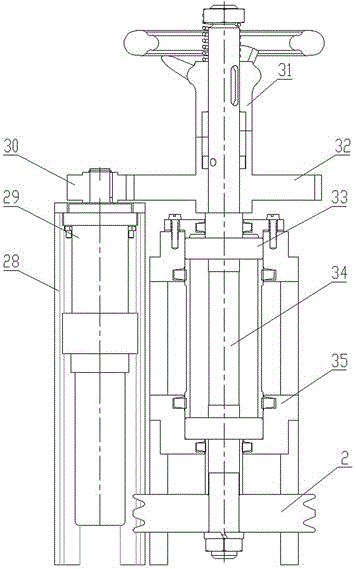

[0037] Such as Figure 1-Figure 6 As shown, a long-distance continuous process transport channel for a hot cell group, including a transport channel 1 set in the hot cell group, a trolley 5 that walks in the transport channel 1 and transfers fuel assemblies between multiple hot cells And steel wire rope 9, one end of steel wire rope 9 is connected with one side of trolley 5, then steel wire rope 9 is connected with the other side of trolley 5 through the pulley combination device that is arranged in the different hot chambers in transport channel 1, and trolley 5 passes slide rail 6 in Transshipment in the transport channel.

[0038] Wherein, the pulley combination device comprises the drive pulley 2 and the first runner 3 arranged in the corresponding transport passage of a heat chamber, the second runner 3 arranged in the corresponding conveyance passage of another heat chamber, and one end of the steel rope 9 is connected with the dolly 5. After one side is connected, the ...

Embodiment 2

[0048] Such as Figure 1-Figure 6 As shown, the inspected object in the 1# hot chamber is transferred to the 3# hot chamber, the operator sends a control signal through the control button arranged in the front area of the operation, and then the operator rotates the rotary handle 19 of the airtight door 7 by the manipulator to compress the Open the device, and then use the manipulator to pull the operating handle 23 to open the corresponding airtight door 7 of the 1# heat chamber, push aside the tray locking block 39 arranged on the trolley 5 and pull the trolley tray 41 into the 1# heat chamber. Or put the inspected object on the trolley tray 41 under the action of the hot room crane, push back and lock the trolley tray 41, close the airtight door 7 and press it with the pressing device, and then operate the control panel in the front area Issue a control command, run the trolley 5 to the station corresponding to the 3# hot chamber receiving the object, open the airtight do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com