Forward and reverse lamination device of hygienic products

A hygienic product and stacking device technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of unsatisfactory high-speed and stable transmission of objects, large volume of cylindrical cams, high manufacturing costs, etc., and achieve low processing costs , high structural stability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

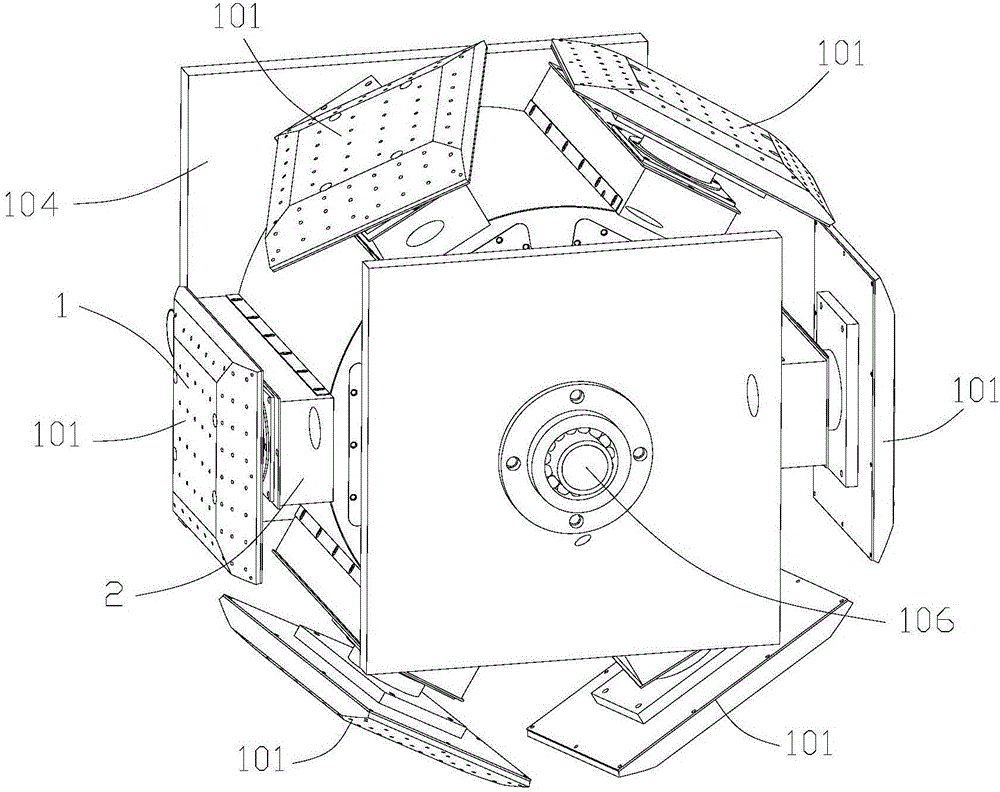

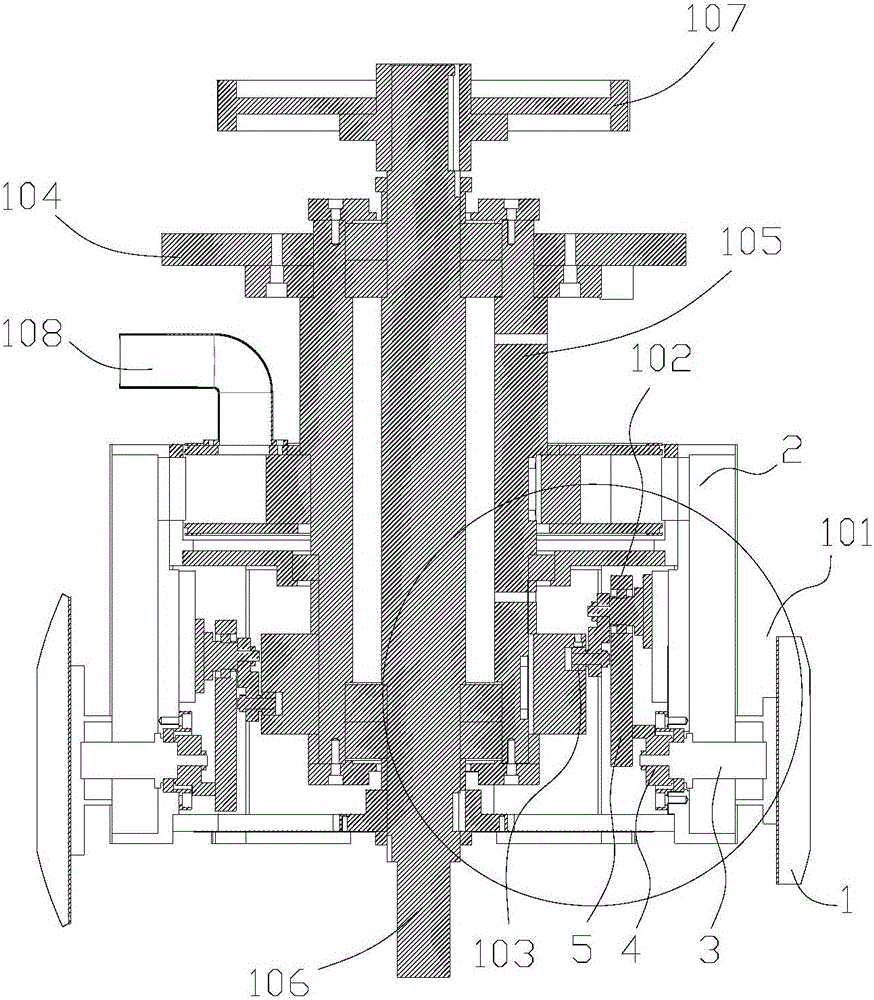

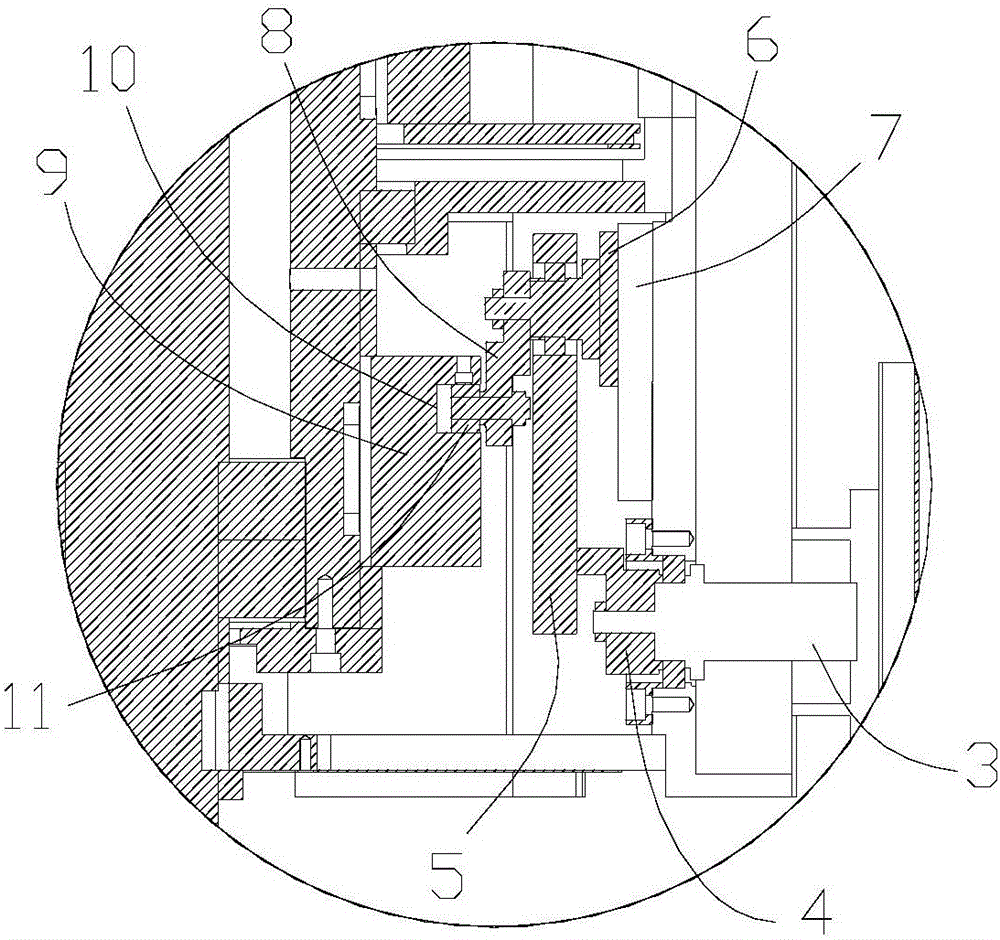

[0021] see Figures 1 to 3 , a front and back lamination device for hygiene products, including a turntable 104, a driving component for driving the turntable 104 to rotate, and a fixed shaft 105. The drive component includes a drive shaft 106 connected to the turntable 104, and a drive part 107 connected to the drive shaft. A cam 9 is fixed on the fixed shaft 105, and a direction changing cam groove 10 is provided on the peripheral surface of the cam. It also includes a plurality of direction adjustment units arranged at intervals on the circumferential surface of the turntable 104 , and the direction adjustment unit has a rotating part 101 , a direction changing part 102 and a guiding part 103 .

[0022] Wherein, the rotating part 101 rotates periodically under the action of the guiding part 103 , which has a rotatable adsorption part 1 , a transmission box 2 fixed on the turntable, and a pivot 3 perpendicular to the rotation plane of the adsorption part 1 . The transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com