Powder bin electric control cabinet with powder ash blowing mentoring system and monitoring method of powder bin electric control cabinet

A monitoring system and electric control box technology, applied in general control systems, control/regulation systems, cleaning methods using gas flow, etc., can solve problems such as concrete quality and construction engineering quality hidden dangers, and achieve obvious social and economic benefits , to avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

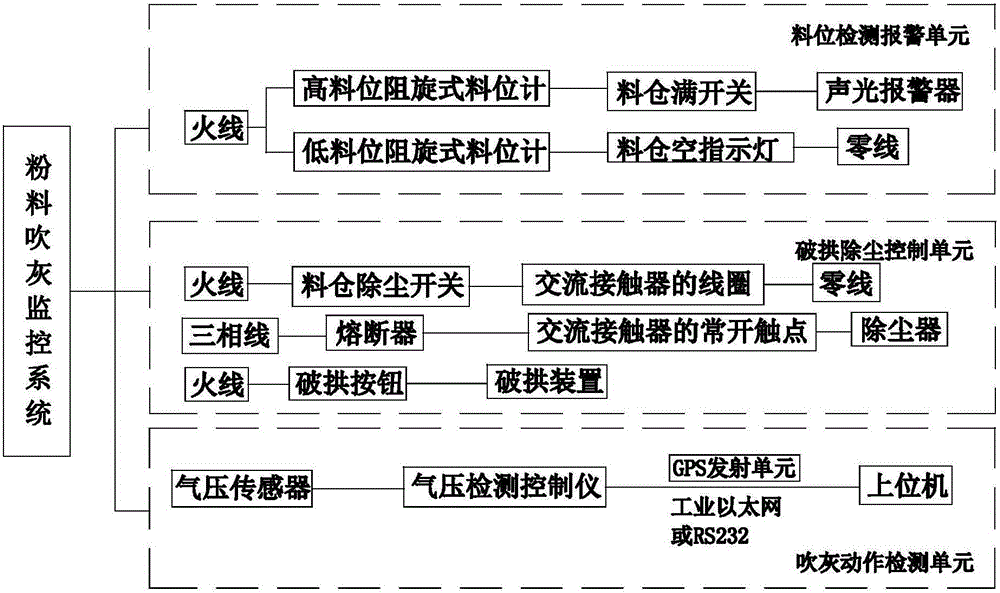

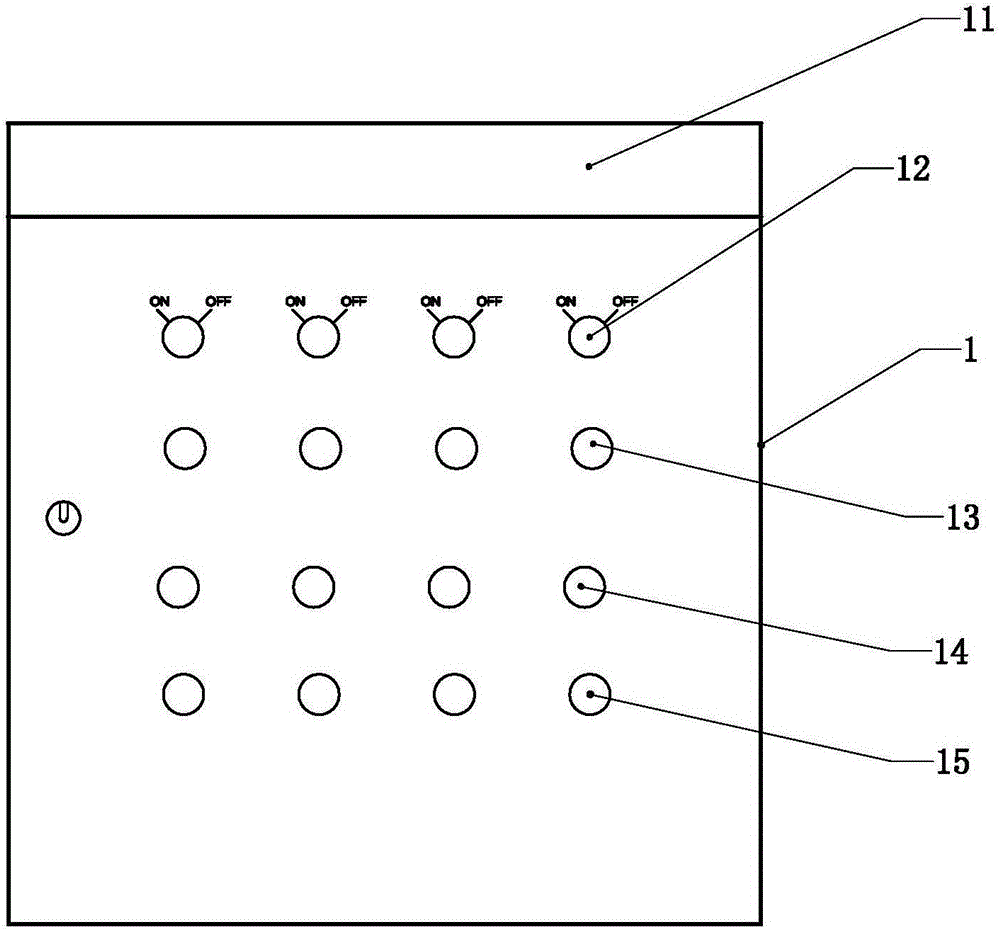

[0037] Such as Figure 1 to Figure 10 As shown, the present invention includes an electric control box, a powder soot blowing monitoring system and a host computer.

[0038] Such as figure 1 As shown, the powder soot blowing monitoring system includes a material level detection and alarm unit, an arch breaking dust removal control unit, a soot blowing action detection unit and a GPS transmitting unit; the material level detection and alarm unit is connected with the silo full switch and silo The air switch is connected, the arch-breaking dust removal control unit is connected with the bin dust removal button on the electric control box, the soot blowing action detection unit is set at the feeding port of the powder bin, and is connected with the upper computer, and the GPS transmitting unit is connected with the soot blowing action detection unit. Units are connected.

[0039] One end of the high material level resistance rotary material level gauge is connected to the 220V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com