Roller core-removable spinning drum mechanism

A withdrawable, reel technology, applied in the field of placing processing machinery, can solve the problems of complexity and high manufacturing cost, and achieve the effects of simple operation, low manufacturing cost and clear working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

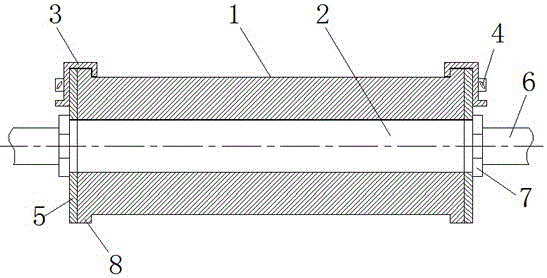

[0015] Such as figure 1 As shown, a textile reel mechanism with a detachable roller core, the reel mechanism is composed of a reel body 1, a roller core 2 and a cloth pressing member 3, and the reel body 1 is an integral body with flanges 8 at both ends. Structure, the roller core 2 is set inside the reel body 1, the two ends of the roller core 2 are provided with a rotating drive shaft 6, and the two ends of the reel body 1 are respectively provided with a reel end disc 5, and the reel end disc 5 passes through the stopper 7. Tighten and fix. The cloth pressing part 3 is set on the flange 8 and the end disc 5 of the reel. The cloth pressing part 3 is provided with an electromagnetic suction device 4, and the cloth pressing part 3 passes through the electromagnetic suction device 4. It is fixedly connected to the side of the reel end disk 5.

[0016] Such as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com