Glass kettle molding machine

A molding machine and kettle technology, applied in glass molding, glass blowing, glass production, etc., can solve the problems of inability to realize automatic production, complex molding process, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

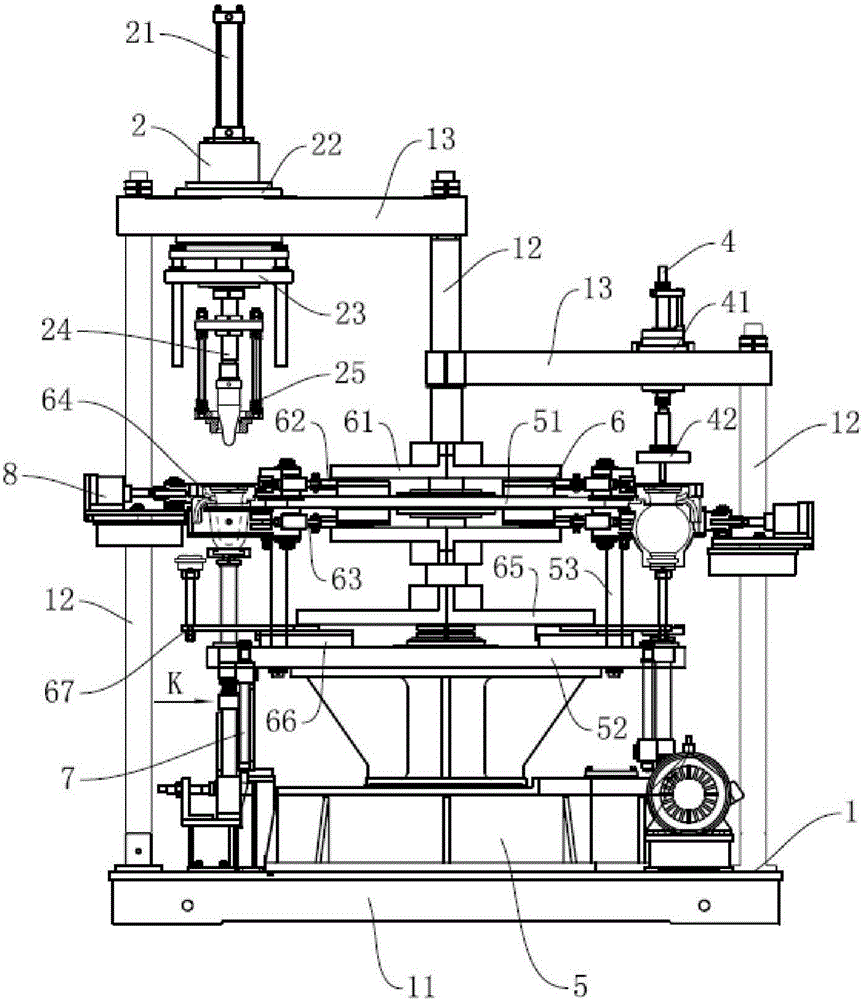

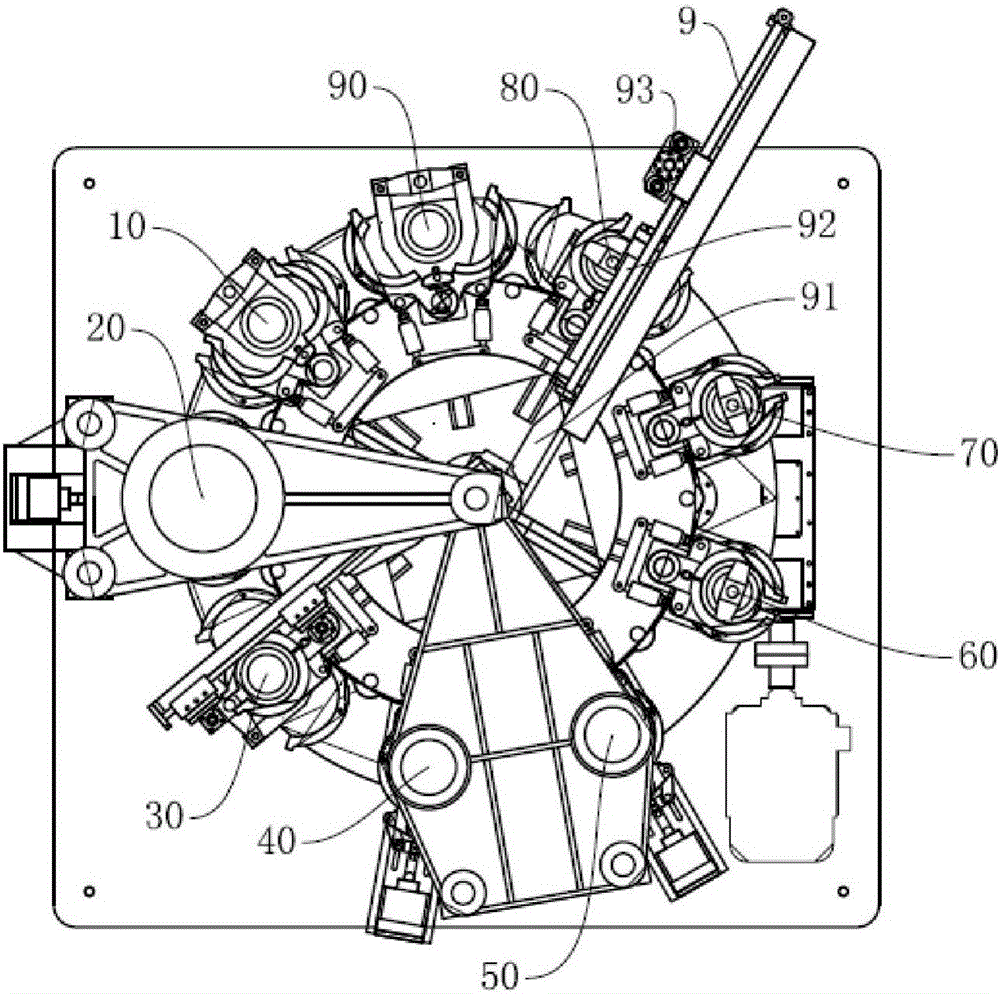

[0031] Combine below Figure 1 to Figure 5 And further illustrate the technical solution of the present invention through specific examples.

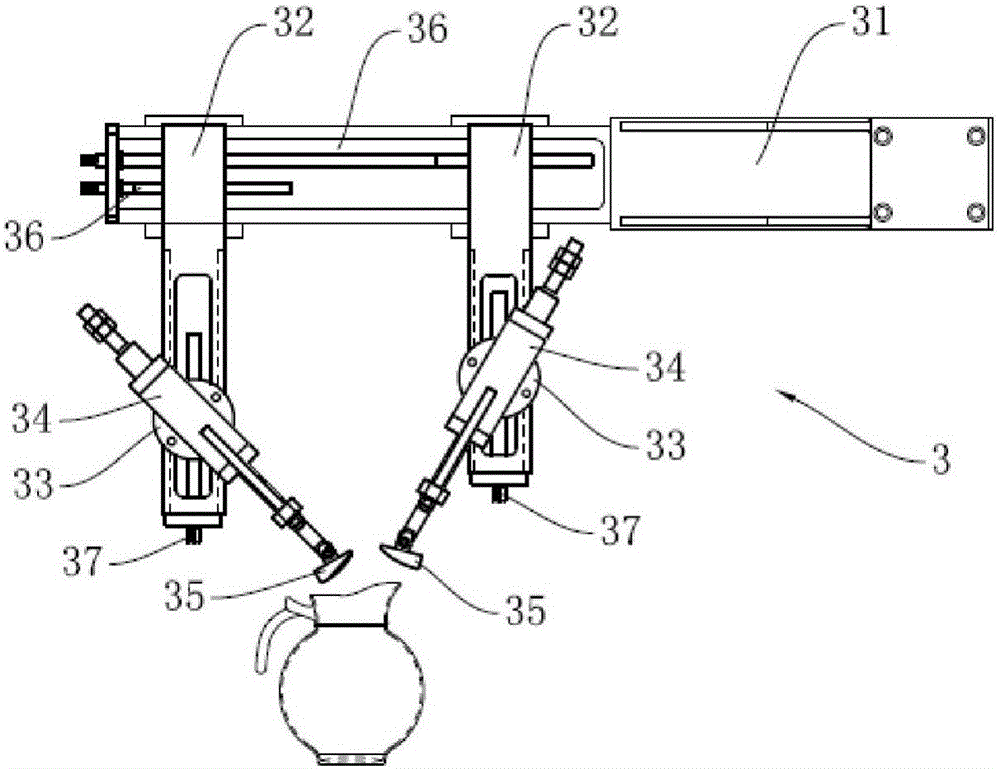

[0032] like figure 1 and figure 2 As shown, a glass jug forming machine includes a frame 1 and a press molding device 2 arranged on the frame 1. The frame 1 is also provided with a mouth molding device 3 and a blow molding device 4. The mouth molding device 3 includes a laterally movable arm 31 arranged on the frame 1. The laterally movable arm 31 is provided with two vertically movable carriages 32. The vertically movable carriage 32 can move horizontally on the laterally movable arm 31, and the vertically movable carriage 32 A cylinder turntable seat 33 is provided, and the cylinder turntable seat 33 can move vertically on the vertically moving carriage 32. The cylinder turntable seat 33 is provided with a spout forming cylinder 34, and the top of the piston rod of the spout forming cylinder 34 is fixed with a spout Push mold 35, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com