Lime powder suspension calcining production line and suspension calcining process thereof

A suspension calcination and production line technology, applied in lime production and other directions, can solve the problems of poor process heat utilization rate, production efficiency and quality, etc., to improve production efficiency and powder lime quality, not easy to environmental pollution, improve heat utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

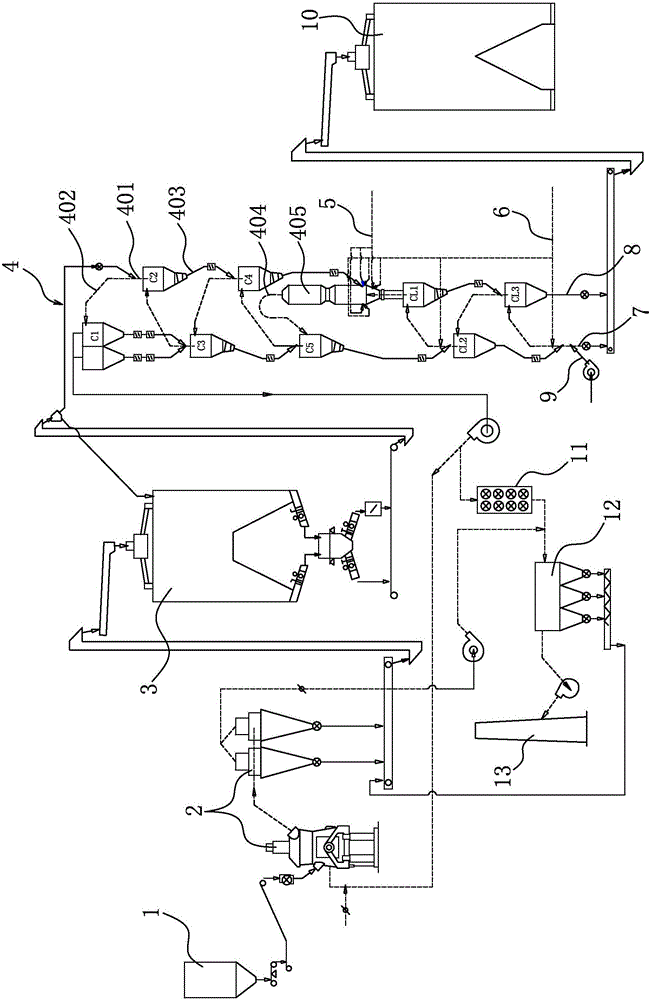

[0013] Now in conjunction with accompanying drawing, the present invention is described as follows.

[0014] The powder lime suspension calcination production line includes crushed limestone storage device 1, limestone powder preparation device 2, feeding device 3, suspension calcination cooling device 4, fuel supply device, screening device, finished product storage device 10, waste gas treatment device 12, crushing The discharge end of the limestone storage device 1 is connected to the feed end of the limestone powder preparation device 2, the discharge end of the limestone powder preparation device 2 is connected to the feed end of the feeding device 3 through a conveying mechanism, and the discharge end of the feed device 3 Connect to the feed end of the suspension calcination cooling device 4. The screening device is arranged at the discharge end of the suspension calcination cooling device 4 , the fuel supply device includes a pulverized coal supply end 5 and a gas suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com