Automobile tire sidewall rubber capable of increasing sidewall hardness

A technology for automobile tires and sidewall rubber, applied in special tires, tire parts, vehicle parts, etc., can solve the problems of easy bulging and damage, poor impact resistance, easy deformation, etc., and achieve long service life and impact resistance. The effect of improved performance and improved flexural resistance

Active Publication Date: 2016-08-31

ZHAOQING JUNHONG CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] The car tire sidewall rubber is mainly used to improve the problem of lack of glue on the sidewall of semi-steel radial tires, but the two applications, for the long-term storage of the car tire sidewalls, are easy to deform, have poor impact resistance, and are prone to bulges and bruises. Problems such as damage cannot be better solved, so it is necessary to develop a car tire side rubber that is resistant to deformation, flexure, impact and long service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 7

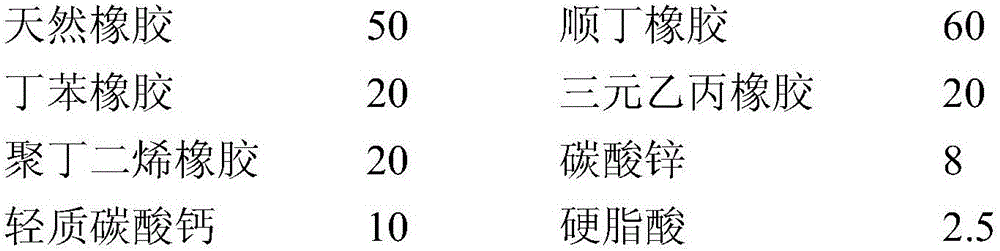

[0040]

[0041] According to the aforementioned preparation method of sidewall rubber compound, by adding PNM modified EP resin, the PNM modified EP resin forms a network structure, which significantly increases the toughness, tensile strength and bending strength of the corresponding sidewall rubber. The hardness of the side rubber has also increased to a certain extent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

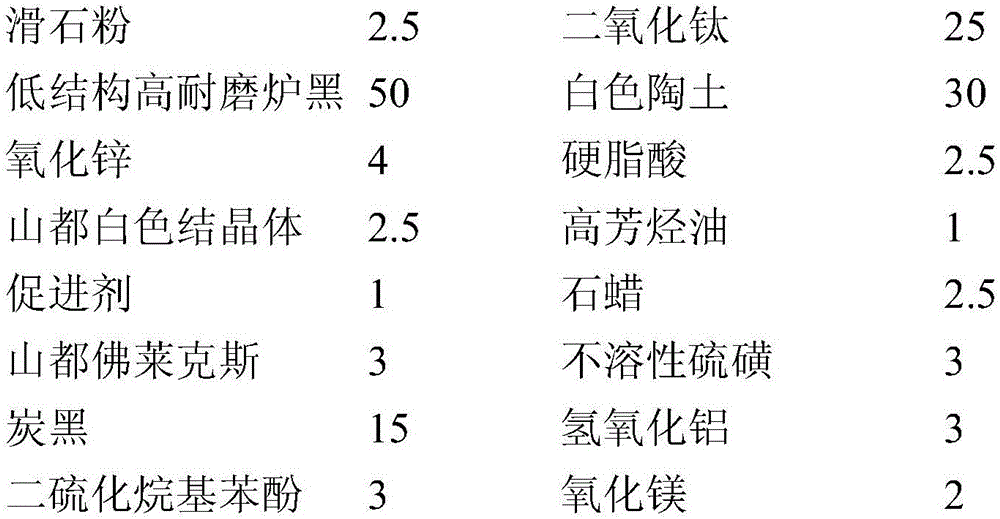

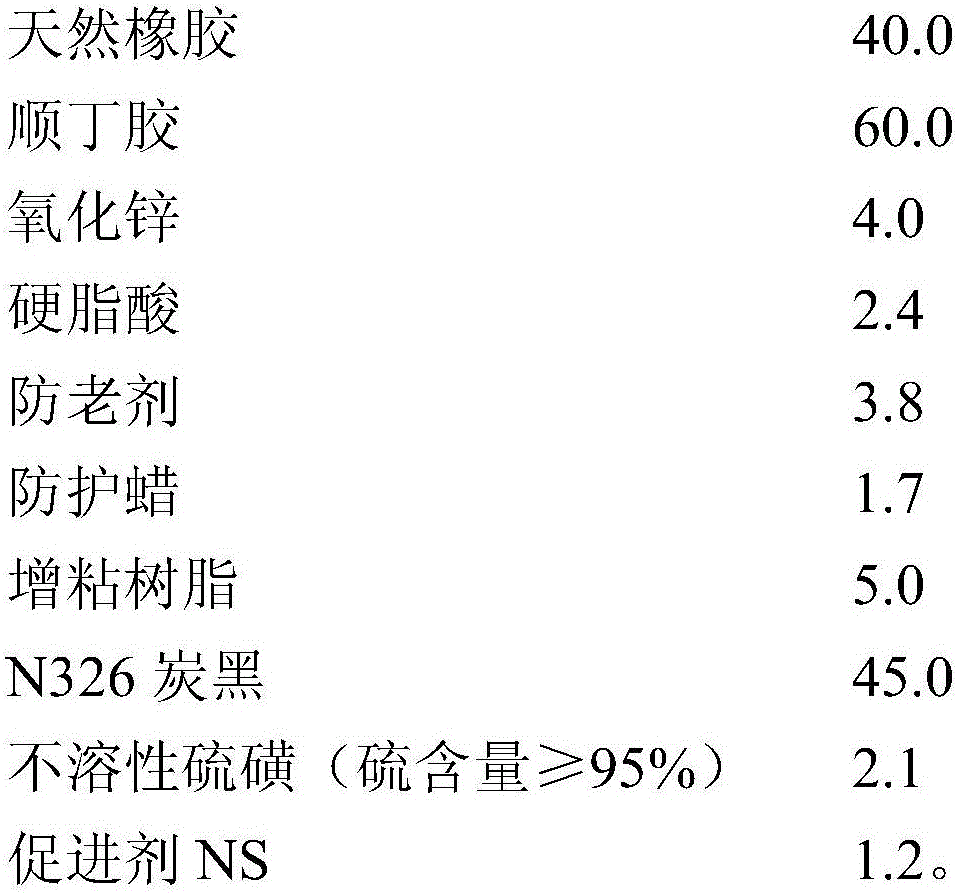

The invention provides an automobile tire sidewall rubber capable of increasing sidewall hardness. The sidewall rubber comprises the following components in parts by weight: 40-50 parts of natural rubber, 50-60 parts of cis-1,4-polybutadiene rubber, 2-8 parts of zinc oxide, 2-4 parts of stearic acid, 2-5 parts of anti-aging agent, 1-3 parts of protective wax, 1-5 parts of tackifying resin, 2-10 parts of hardening resin, 0.2-1 part of curing agent, 40-60 parts of N326 carbon black, 2-4 parts of high-dispersivity insoluble sulfur (the sulfur content is greater than or equal to 95%), 1-3 parts of accelerator NS, 1-2 parts of vulcanizing agent TB710 and 2-12 parts of 6700 resin. The sidewall rubber has the advantages of deformation resistance, flexing resistance, impact resistance, long service life and the like.

Description

technical field [0001] The invention belongs to the technical field of tire manufacturing, and in particular relates to a sidewall rubber compound for increasing the hardness of the sidewall of an automobile tire. Background technique [0002] Tires are one of the important parts of the car. They are in direct contact with the road and play an important role. First, they work together with the car suspension to ease the impact of the car while driving and ensure that the car has good seating comfort and ride comfort. At the same time, it is necessary to ensure that the wheels and the road have good adhesion, and improve the traction, braking and passability of the car; in addition to bearing the weight of the car, etc., the important role played by tires on the car is more and more popular. attention. [0003] At present, the radial structure tire pioneered by the French Michelin company is known as a revolution in the tire industry due to the significant improvement in ser...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L9/00C08L7/00C08L91/06C08K13/02C08K3/22C08K5/09C08K3/04C08K3/06B60C1/00

CPCB60C1/0025C08L7/00C08L9/00C08L2205/035C08L91/06C08K13/02C08K2003/2296C08K5/09C08K3/04C08K3/06

Inventor 林丛海张碧俊丁金刚吉年康覃进明

Owner ZHAOQING JUNHONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com