Carbonizing device

A carbonization device and carbonization technology, used in special forms of dry distillation, biofuels, coke ovens, etc., can solve the problems of waste of resources, dust and smoke pollution, low yield and other problems, to prevent high temperature spontaneous combustion, high quality charcoal, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

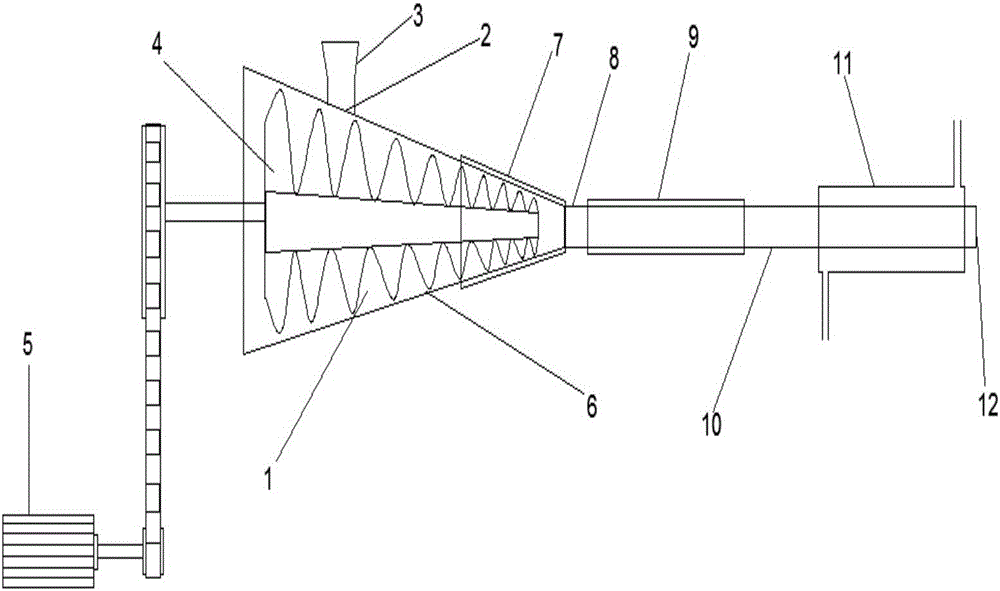

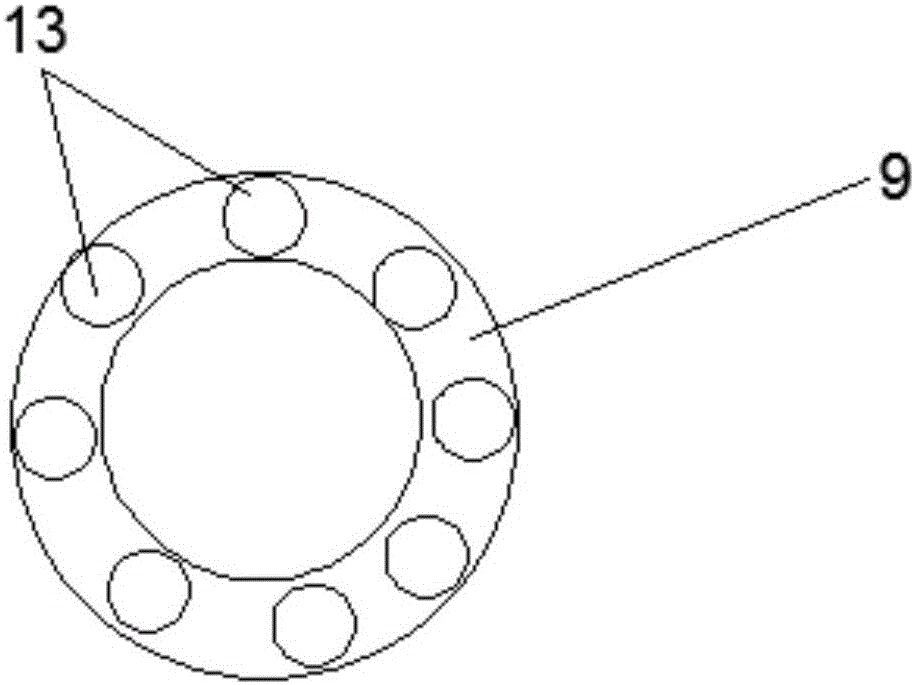

[0018] With reference to accompanying drawing, in order to enable the present invention to realize the designed effect, the present invention adopts following embodiment: a kind of carbonization device, comprises rod forming machine and motor, and described rod forming machine is equipped with screw propeller, and described screw propeller A belt is installed, and the other end of the belt is connected to the motor. The rod forming machine is equipped with a directional cone sleeve, and the directional cone sleeve is equipped with an electric heating sleeve. The rod forming machine is equipped with a guide tube, and the guide tube is equipped with There is a carbonization pipe, the carbonization pipe is equipped with a discharge pipe, the discharge pipe is equipped with a cooling box, the cooling box is provided with a water inlet, the cooling box is provided with a water outlet, and the discharge pipe is provided with an outlet feed port.

[0019] As a preference, the rod for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com