Method for improving liquor quality by storing strength-flavor type white wine with oak barrel

A technology of Luzhou-flavor liquor and oak barrels, applied in the field of liquor storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Store liquor in 225L new American oak barrels, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room with a temperature of 25°C and a humidity of 70%. , stored for a total of 6 months, and then transferred to old oak barrels for 1 year under the same conditions. Then take it out and enter the post-processing process, filling and packaging into finished wine.

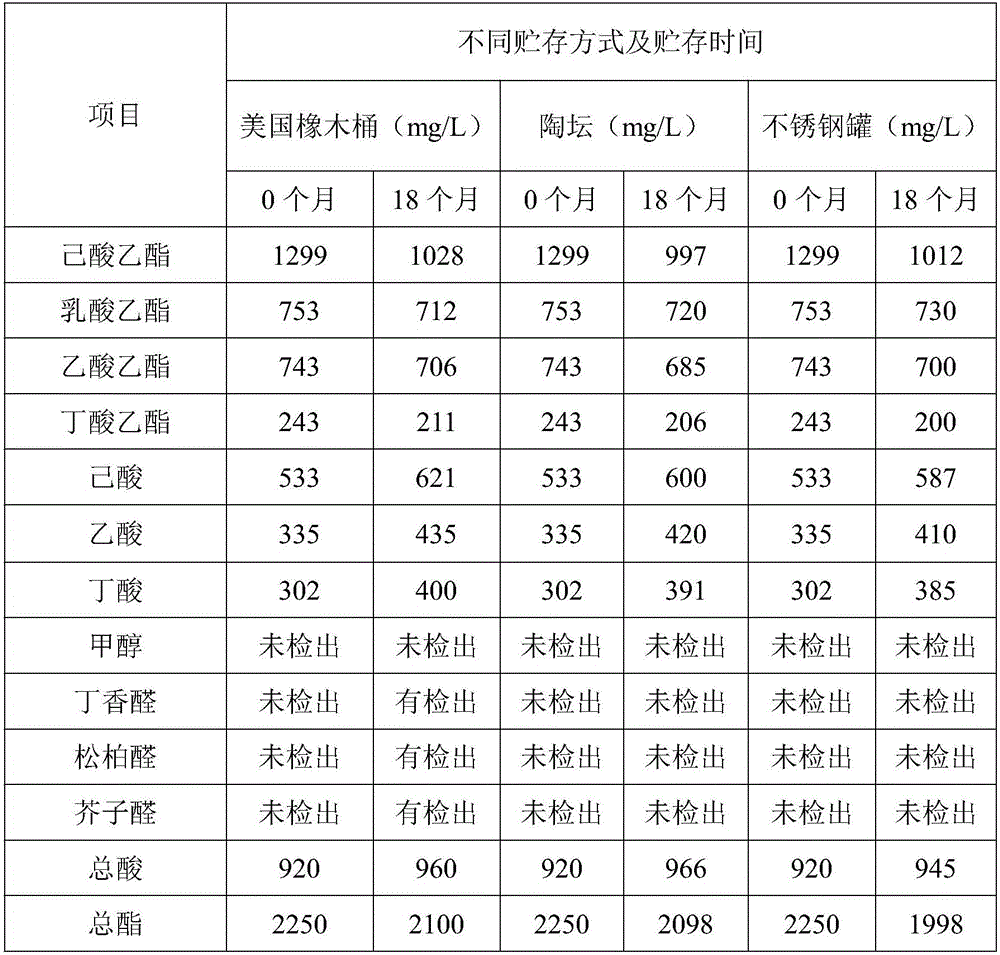

[0023] Liquor stored in oak barrels and liquor stored in ceramic altars and stainless steel tanks for the same period of time were tasted and evaluated, the loss rate was calculated and the main aroma components were determined. The results are shown in Table 1, Table 2, Table 3, Table 4 and Table 5 .

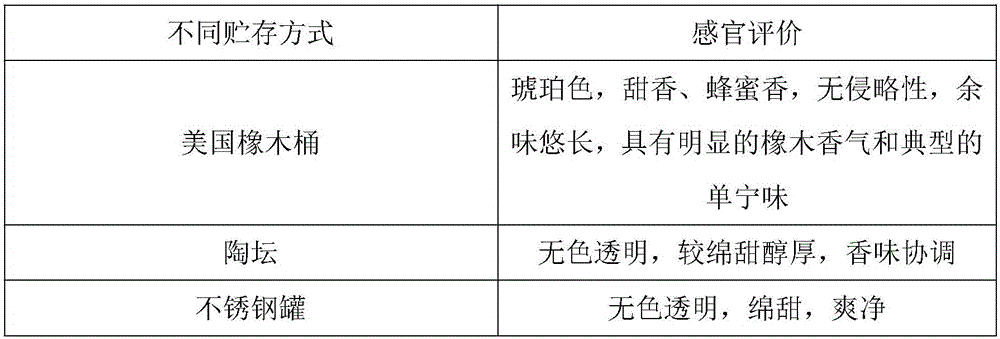

[0024] Table 1. Sensory evaluation results of liquor stored in different containers

[0025]

[0026] Table 2. Loss rate after storage in different containers

[0027] different storage methods...

Embodiment 2

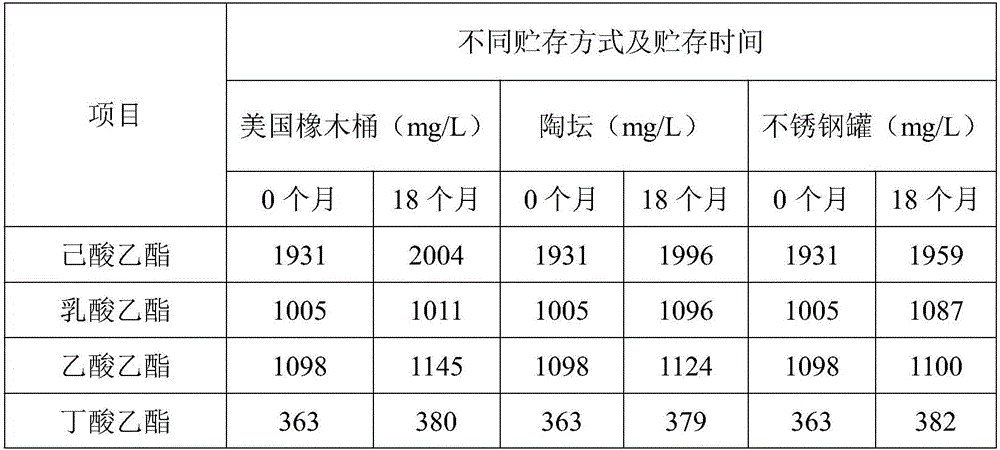

[0037] Store liquor in 350L new French oak barrels, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room with a temperature of 22°C and a humidity of 65%. , stored for a total of 6 months, and then transferred to old oak barrels for 1 year under the same conditions. Then take it out and enter the post-processing process, filling and packaging into finished wine. Liquor stored in oak barrels and liquor stored in pottery jars and stainless steel tanks for the same period of time were tasted and evaluated, the loss rate was calculated and the main aroma components were determined. The results are shown in Table 6, Table 7, Table 8, Table 9 and Table 10. .

[0038] Table 6. Sensory evaluation results of liquor stored in different containers

[0039]

[0040] Table 7. Loss rate after storage in different containers

[0041] different storage methods

Attrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com