Small-caliber circular knitting machine plaiting device

A circular weft machine, small-caliber technology, used in weft knitting, textiles, papermaking, knitting, etc., can solve the problem that the yarn tension cannot be measured and adjusted online, the parameter design affects the coil coverage effect, and the multi-layer weaving structure cannot be achieved. and other problems, to achieve the effect of convenient large-scale production and application, good market prospects and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

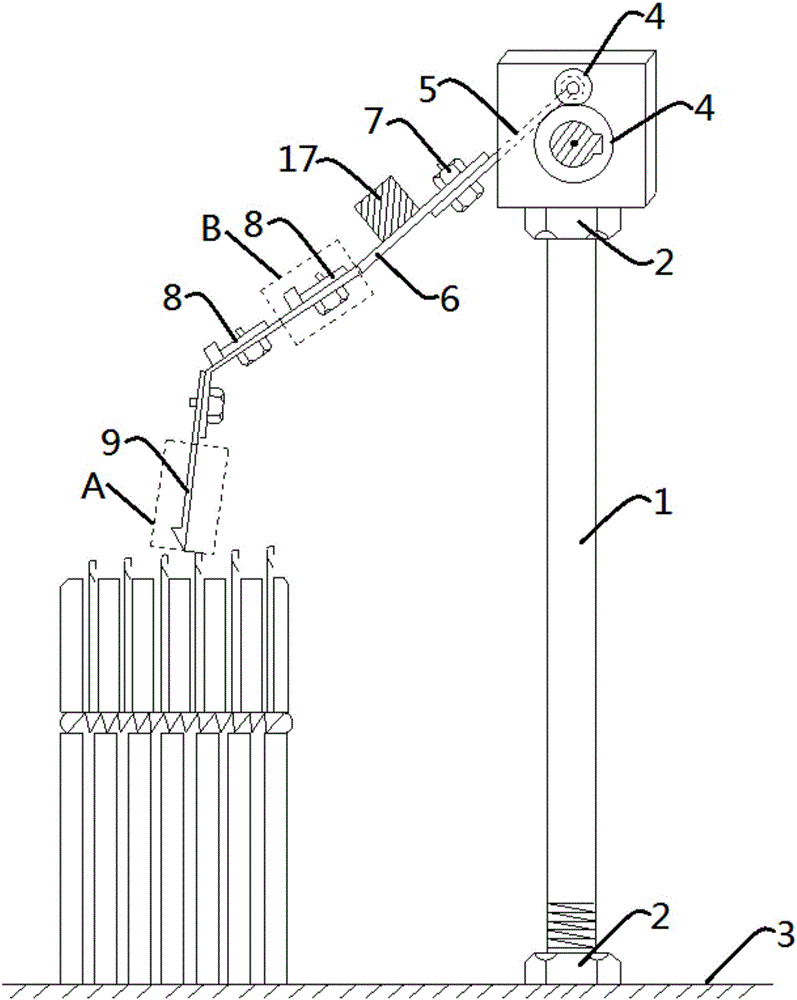

[0025] Embodiment 1: refer to figure 1 , 4 , Shown in 5, the plating device of the small-diameter circular weft machine of the present invention comprises a support rod 1, and its material is an aluminum alloy casting (GB / T 3251-2006), and the height of the support rod 1 is 200mm, and its diameter is 10mm. The bottom end of the support rod 1 is fixed on the working surface 3 of the syringe through the nut 2, the top end is connected with the height adjustment device, and is fixed with the bottom of the housing of the height adjustment device through the nut 2. Two of the gears 4 meshing with each other have a diameter of 6mm (upper gear) and 12mm (lower gear) respectively. Utilize the rotation control lever 5 that is connected with the upper gear 4 to realize the up and down height adjustment of the plating yarn guide assembly, and its adjustment angle range is 5-135°. The rotation control rod 5 is connected with the top end of the plating yarn guide rod 6 through a rotation...

Embodiment 2

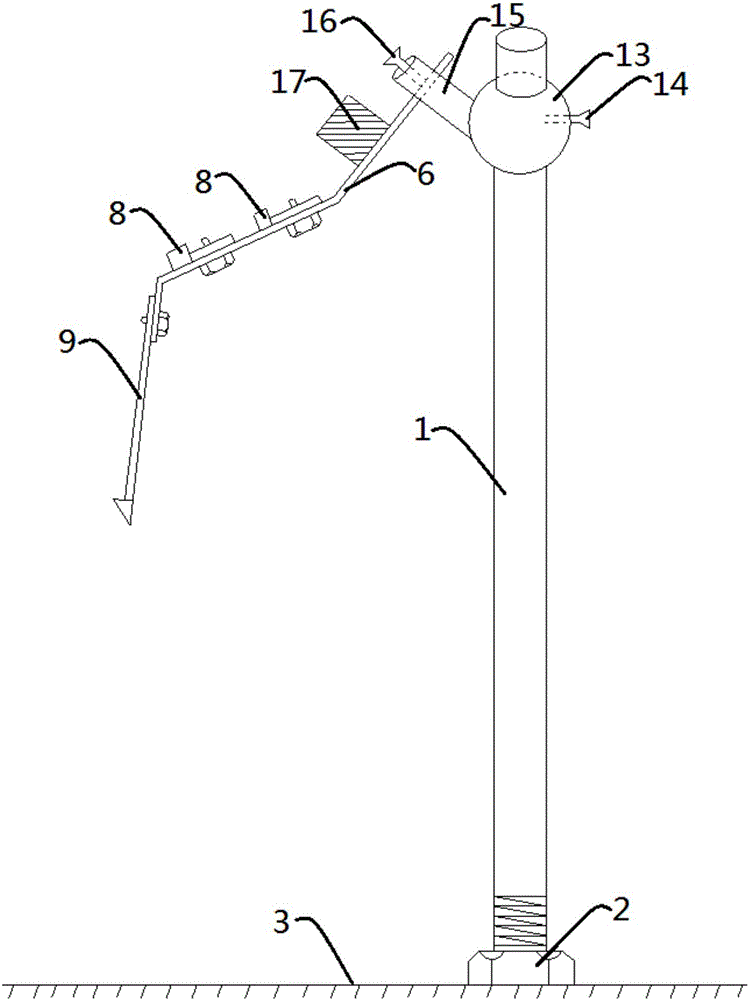

[0026] Embodiment 2: refer to figure 2 As shown, the plating device of the small-diameter circular weft machine of the present invention includes a support rod 1 made of stainless steel (06Cr19Ni10), the height of the support rod 1 is 200mm, and the diameter is 10mm. Rotating pair 13 inner diameter is 10mm, and outer diameter is 25mm, and rotating pair 13 can rotate around support bar 1, and its rotation angle range is 0-360 °, is fixed on the different heights of support bar 1 by positioning screw 14. The moving pair 15 adopts screws 16 to be fixed at different positions of the plating yarn guide rod 6, so as to realize the different lengths of the plating yarn guide rod 6 to expand and contract. The length of the main body of the plating yarn guide rod 6 is 80 mm, the height of the plating yarn guide rod 6 and the plating yarn guide assembly on it is 120 mm, and the thickness is 2 mm. On the plating yarn guide rod 6, there is a bending angle of 160° between the yarn tensio...

Embodiment 3

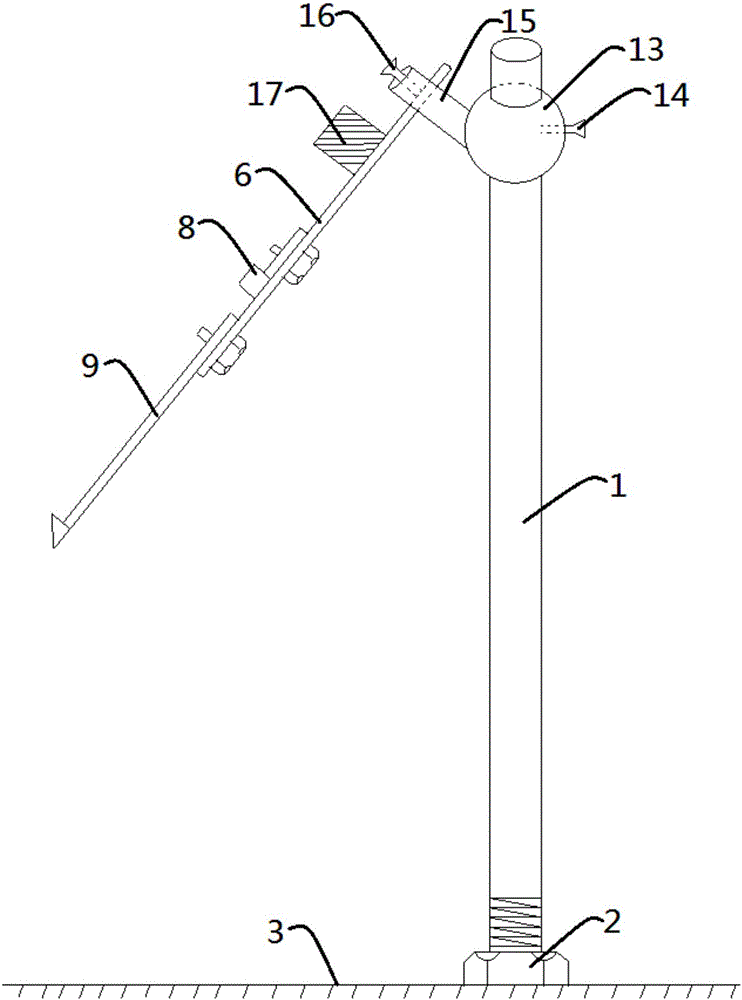

[0027] Embodiment 3: refer to image 3 , The yarn plating device of the small-diameter circular weft machine of the present invention includes a support rod 1, the material is alloy structural steel (12Cr2MoG), the height of the support rod 1 is 200mm, and the diameter is 10mm. Rotating pair 13 inner diameter is 10mm, and outer diameter is 25mm, and rotating pair 13 can rotate around support bar 1, and its rotation angle range is 0-360 °, is fixed on the different heights of support bar 1 by positioning screw 14. The moving pair 15 adopts screws 16 to be fixed at different positions of the plating yarn guide rod 6, so as to realize the different lengths of the plating yarn guide rod 6 to expand and contract. The total length of the plating yarn guide rod 6 and the plating yarn guide assembly on it is 120mm, and the thickness of the plating yarn guide rod 6 is 2mm, and the yarn tension controller 17 and the yarn guide tripod 8 are installed successively, and the yarn guide trip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com