Prefabricated pretensioned prestressed underground continuous wall and construction method thereof

An underground diaphragm wall and prestressing technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that cannot be directly used as basement exterior walls, the flatness of walls is difficult to control, and irregular water seepage on walls, etc., to achieve Good use value and promotion value, convenient transportation and hoisting, and the effect of reducing deflection and controlling cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

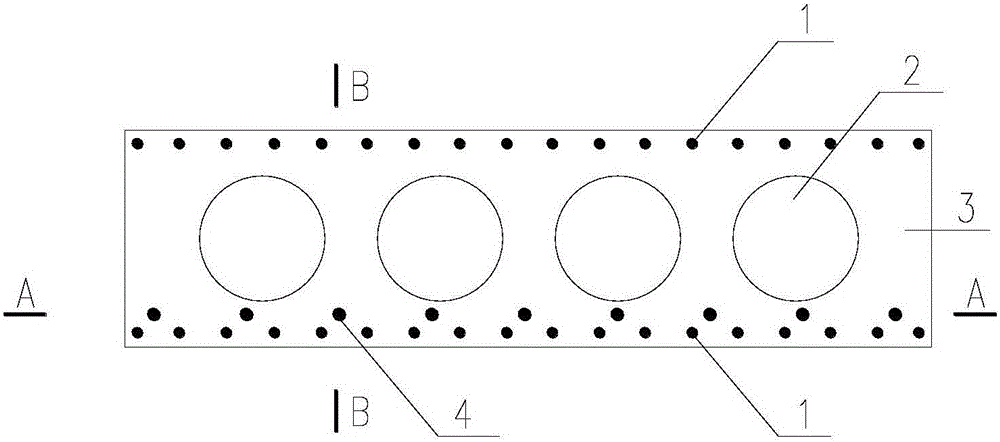

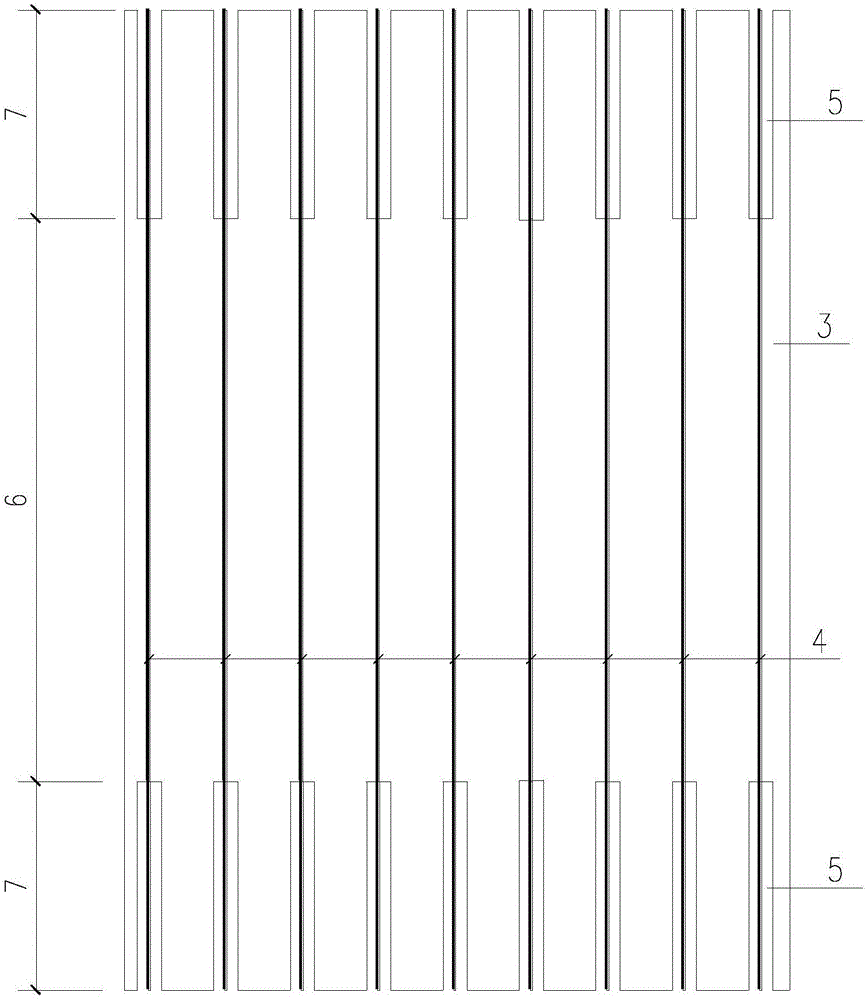

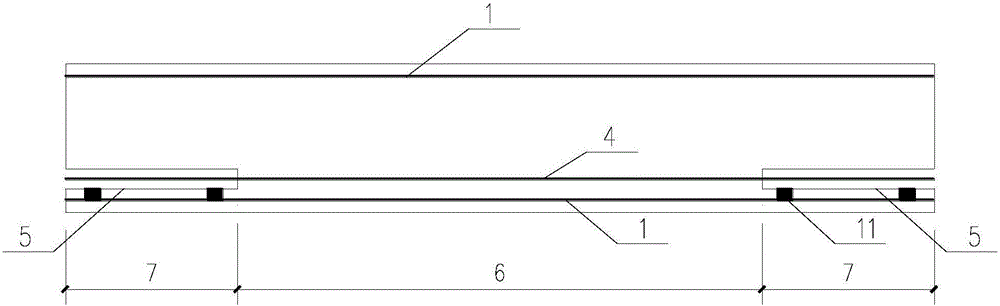

[0037] The prefabricated pretensioned prestressed underground diaphragm wall and its construction method of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] The design idea of the prefabricated pre-tensioned prestressed ground connection wall of the present invention is to apply pretensioning method prestress to the ground connection wall, apply prestress to the area with large tension, and not apply prestress to the area with small tension or compression. Before the reinforcement is prestressed, the reinforcement cage is placed flat on a special site and the formwork is used to support the mold, while the pre-tensioned reinforcement and the embedded casing are fixed on the reinforcement cage, and the outer surface of the embedded casing can be coated with lubricating materials for convenience. take out. Perform prestressed stretching of the pre-tensioned steel bars between the pre-embedded sleeves arranged opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com