Absolute type grating ruler and measurement method

A measurement method and technology of grating ruler, which are applied in the direction of transmitting sensing components by optical devices, can solve the problems of limited coding range, high code error rate, measurement error, etc., so as to reduce the grating error rate, high measurement accuracy, and The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

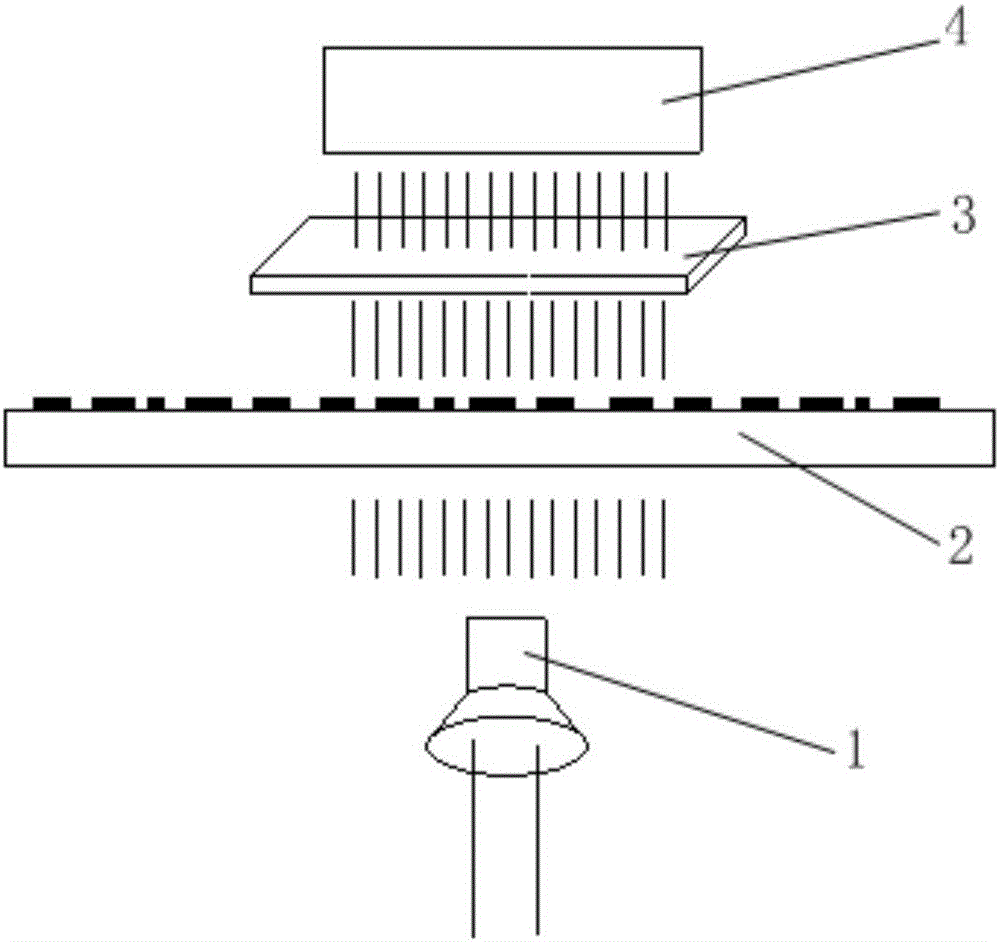

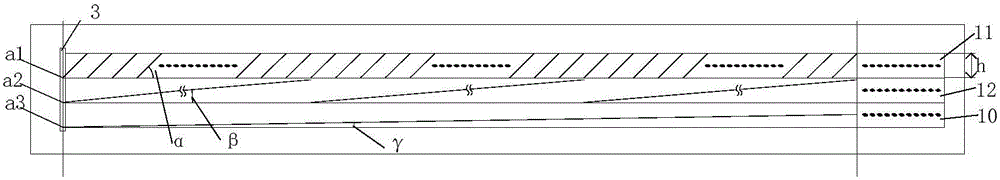

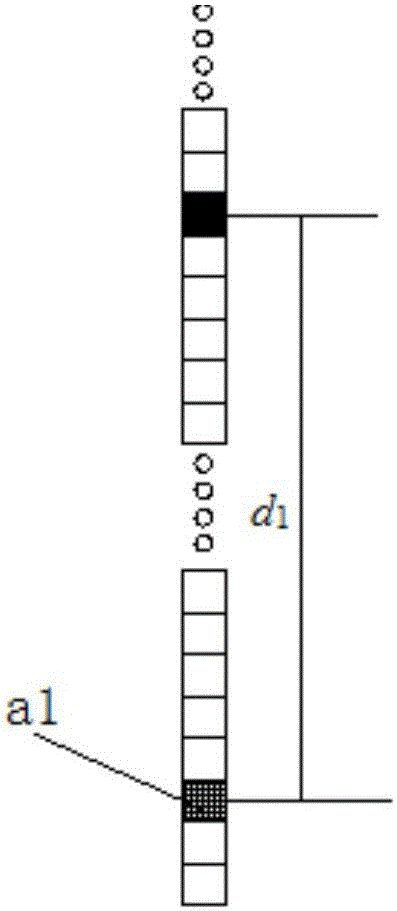

[0053] Example 1 reference figure 1 and figure 2 , an absolute grating ruler, including a parallel light source module 1, a scale grating 2, a photodetector 3 and a signal processing module 4, a base track 10 and a plurality of coding tracks are arranged on the scale grating 2, and the base track 10 includes a Grating stripes with inclined directions, each coding track includes a plurality of grating stripes that are uniformly arranged periodically and inclined to the measurement direction, and each coding track has a different period respectively, and the parallel light beam emitted by the parallel light source module 1 passes through the scale After the grating 2 is irradiated onto the photodetector 3, the photodetector 3 is used to collect the arriving optical signal and convert it into a measurement electrical signal before sending it to the signal processing module 4, which is used to process and analyze the measurement electrical signal The measured values of multipl...

Embodiment 2

[0066] Embodiment 2, a method of measuring an absolute grating ruler, comprising steps:

[0067] S1. Install the scale grating 2 on the object to be measured, and drive the object to be measured to move;

[0068] S2. The parallel light beam emitted by the parallel light source passes through the scale grating 2 and then irradiates on the photodetector 3;

[0069] S3. The photodetector 3 collects the arriving optical signal and converts it into a measurement electrical signal and sends it to the signal processing module 4;

[0070] S4. The signal processing module 4 analyzes and obtains the measured values of the base track 10 and multiple encoded tracks after processing the measured electrical signals, and then calculates and obtains the absolute position measured values, specifically including steps S41 to S43:

[0071] S41. After the signal processing module 4 preprocesses the measurement electrical signal, it divides and obtains a plurality of measurement image blocks corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com