Strength property evaluating device suitable for solid granular catalyst

A solid particle and evaluation device technology, which is applied in the direction of strength characteristics, measuring devices, and test wear resistance, can solve the problems of limited sedimentation, inability to completely simulate catalyst wear and crushing process, etc., and achieve stable test data, simple structure, Ease of disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

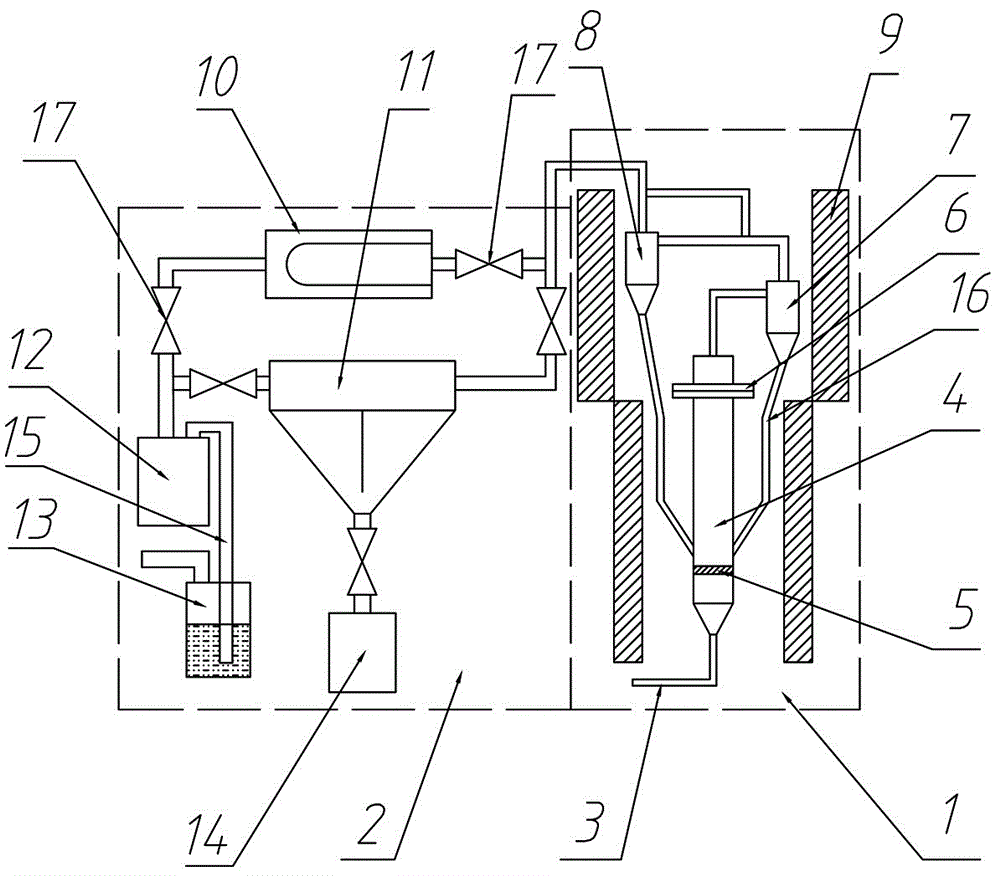

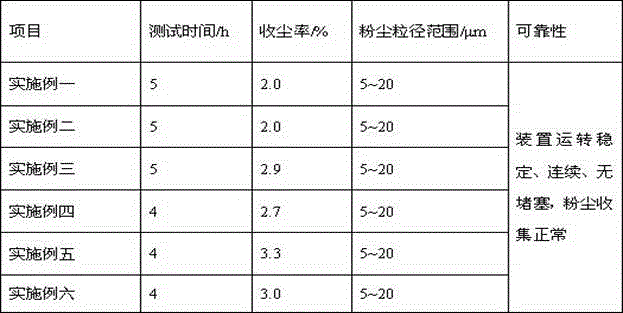

[0022] use figure 1 The device shown was tested with spherical Mo / HZSM-5 catalyst particles. The fluidization tester 4 is made of quartz, the gas distribution plate 5 is sintered from quartz, the particle size range of the catalyst to be tested on it is 50-100 μm, the loading amount is 5g, and the temperature of the external heating furnace 9 is 200°C. The primary gas-solid separator 7 and the secondary gas-solid separator 8 are all cyclone separators, the dust filter tank 10 is embedded with a cellulose filter cartridge, the dust settler 11 is equipped with a vertical baffle, and the adsorption liquid in the fine dust washing tank 13 For water, the valve 17 between the dust settler 11 and the dust collection tank 14 is a stop valve, and the remaining valves 17 are ball valves. The test time, dust collection rate, dust particle size range, stability and blockage are shown in Table 1.

Embodiment 2

[0024] use figure 1 The device shown was tested with spherical Mo / HZSM-5 catalyst particles. The fluidization tester 4 is made of quartz, and the gas distribution plate 5 is sintered from quartz. The particle size of the catalyst to be tested on it is 100-200 μm, and the loading amount is 50 g. The temperature of the external heating furnace 9 is 500 ° C. The primary gas-solid separator 7 and the secondary gas-solid separator 8 are all cyclone separators, the dust filter tank 10 is embedded with a cellulose filter cartridge, the dust settler 11 is equipped with a vertical baffle, and the adsorption liquid in the fine dust washing tank 13 It is a NaCl aqueous solution with a mass fraction of 1%, and the valves 17 are all stop valves. The test time, dust collection rate, dust particle size range, stability and blockage are shown in Table 1.

Embodiment 3

[0026] use figure 1 The device shown was tested with spherical Mo / HZSM-5 catalyst particles. The fluidization tester 4 is made of quartz, the gas distribution plate 5 is sintered from quartz, the particle size range of the catalyst to be tested on it is 200-300 μm, the loading amount is 100g, and the temperature of the external heating furnace 9 is 800°C. The primary gas-solid separator 7 and the secondary gas-solid separator 8 are all cyclone separators, the dust filter tank 10 is embedded with a cellulose filter cartridge, the dust settler 11 is equipped with a vertical baffle, and the adsorption liquid in the fine dust washing tank 13 0.5% Na by mass fraction 2 CO 3 Aqueous solution, valve 17 are ball valves. The test time, dust collection rate, dust particle size range, stability and blockage are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com