Method for determining aluminum content in composite swelling agent by microwave digestion-graphite furnace atomic absorption method

A technology of graphite furnace atom and compound leavening agent is applied in the field of detection and analysis, which can solve the problems of economic loss of aluminum-containing products, inaccurate detection results, expensive instruments, etc., to eliminate ion interference, improve measurement sensitivity, and improve measurement sensitivity. and precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

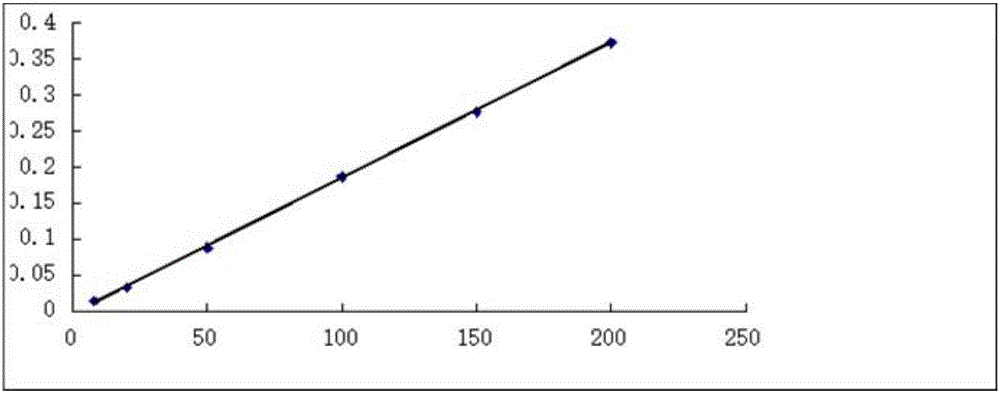

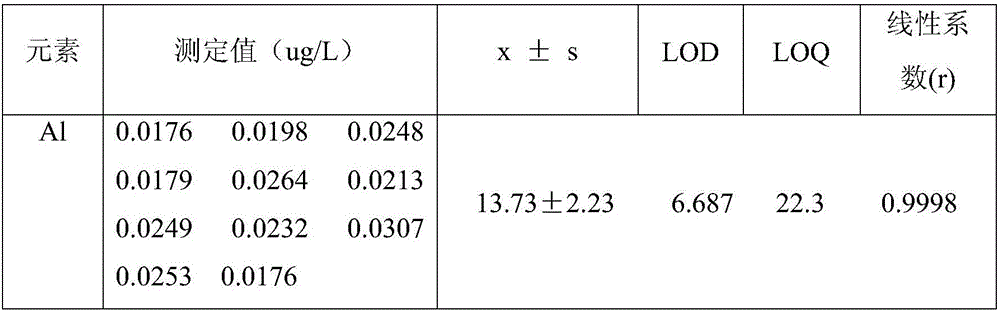

Image

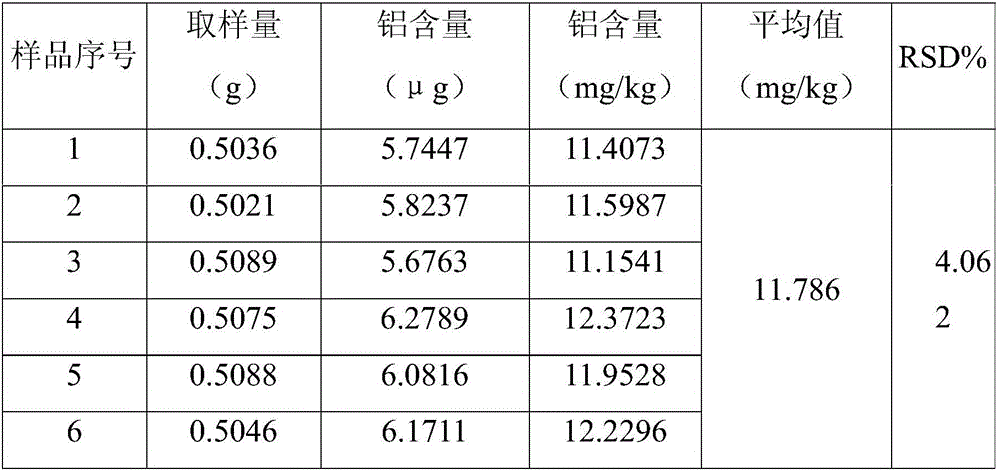

Examples

Embodiment 1

[0025] (1) Use microwave digestion sample for pretreatment:

[0026] Weigh 0.5000g of the composite leavening agent sample after drying at 85°C for 4 hours, put it in a microwave digestion tank, add 4ml of nitric acid, and then digest it after tightening the lid; react at 85°C for 10 minutes, React for 10 minutes, react at 160°C for 10 minutes, and react at 190°C for 10 minutes; take it out after cooling, and put the acid on a temperature-controlled electric heating plate at 160°C to the size of a soybean grain, let it cool and transfer the digestive juice Put it into a 50ml volumetric flask, wash the jar and the inner cover with water for 4 times, put the lotion in the volumetric flask and set the volume to the mark, mix well to obtain the sample solution to be tested, and set aside; prepare a blank control solution at the same time;

[0027] (2) adopt graphite furnace atomic absorption method to measure the content of aluminum in the composite leavening agent:

[0028] a. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com