High-voltage high-power power battery test equipment

A power battery and testing equipment technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems affecting the development of tester manufacturers and related supporting enterprises, heavy economic burden, etc., to reduce the possibility of damage to equipment, Eliminate potential hazards and stabilize the effect of outputting high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

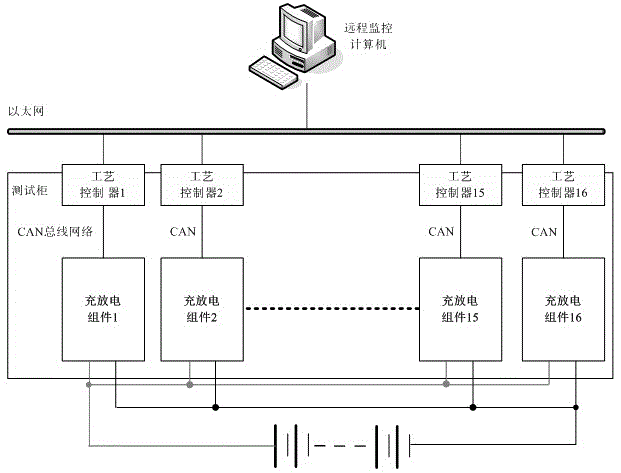

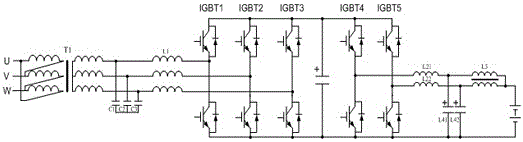

[0015] refer to figure 1 As shown, the present invention discloses a high-voltage high-power power battery testing equipment, including a remote monitoring computer used as a host computer for centralized control and eight main cabinets connected to the remote monitoring computer through Ethernet, each There are two parallel channels in the main cabinet. Each channel is composed of a process controller and a charging and discharging component connected to the process controller through the CAN bus network. The output ends of the charging and discharging components are connected in parallel through a power cable. The channels can work independently or be connected in parallel arbitrarily. The operation output between the master node and each slave node is coordinated through the internal CAN network signal. Each channel outputs 1000V / 125A / 125KW, and eight mast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com