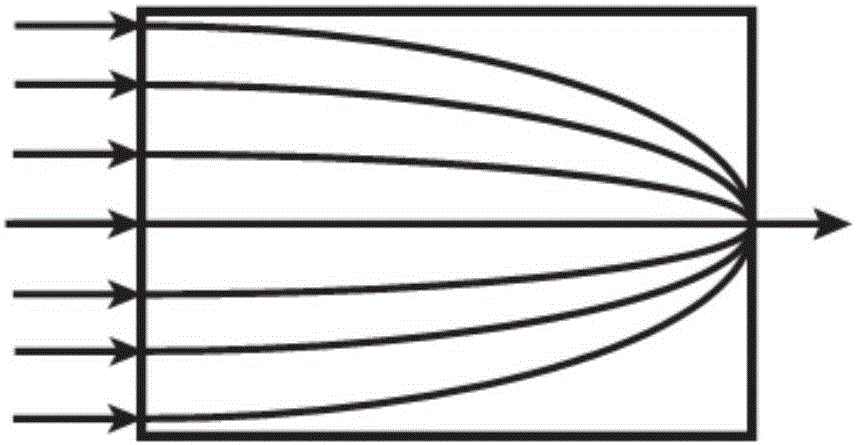

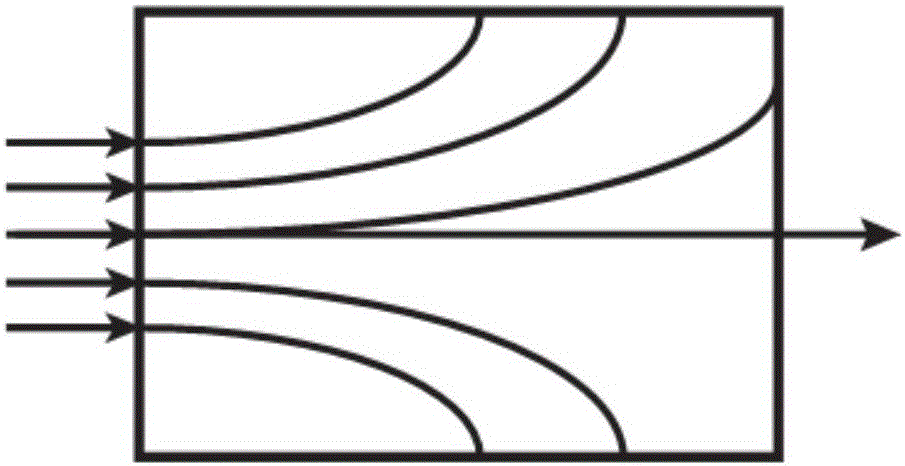

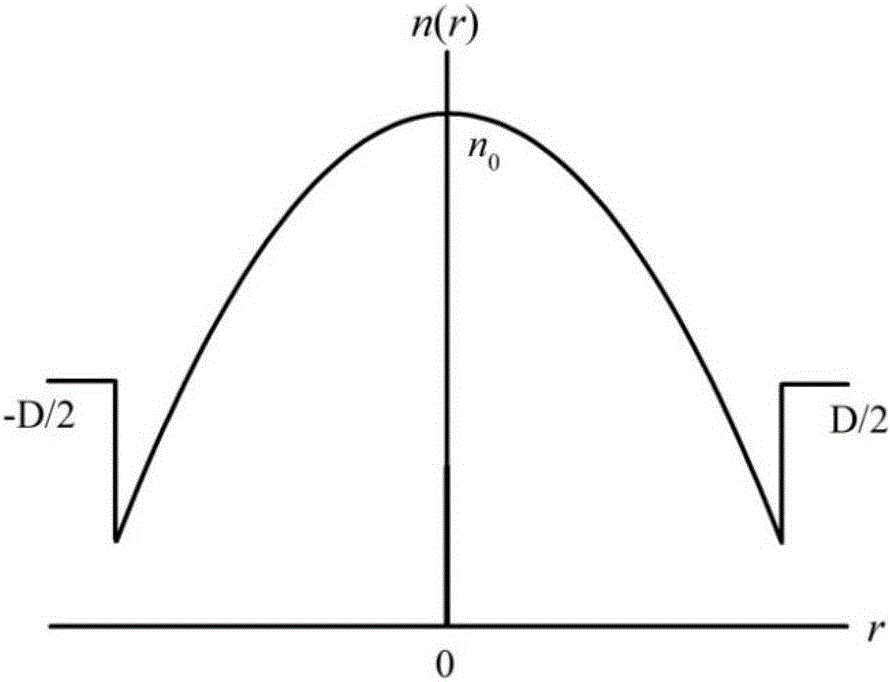

Gradient refractive index quartz glass lens

A gradient refractive index, quartz glass technology, applied in the lens, glass production, glass molding and other directions, can solve the problem that the quartz glass lens does not have good optical properties, achieve short preparation time, reduce use requirements, single production volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) A quartz glass liner with a diameter of 31mm and a thickness of 2mm is installed on the PCVD equipment and injected with SiCl 4 、C 2 f 6 、GeCl 4 , O 2 gas, the furnace heating temperature is 1100°C, the deposition begins under the action of high-frequency microwaves, the initial C 2 f 6 content at the maximum, GeCl 4 content is at a minimum, followed by C 2 f 6 The dosage is gradually reduced, GeCl 4 Gradually increase the dosage, a certain stage C 2 f 6 Reduce to 0, continue to pass GeCl 4 Deposition, the whole process of deposition takes 8 hours, and PCVD automatically finishes the whole deposition process.

[0061] (2) After the deposition is completed, transfer the liner to the shrink furnace and shrink at 2100°C. The liner rotates at a speed of 40r / min, and the temperature program is set. After the seal is formed from the middle, it expands to both sides and reaches the center. The channels are completely closed and condensed into a GRIN rod with a ...

Embodiment 2

[0068] (1) A quartz glass liner with a diameter of 35mm and a thickness of 3mm is installed on the PCVD equipment and injected with SiCl 4 、C 2 f 6 , SF 6 , O 2 Gas, the furnace body heating temperature is 1100°C, and the deposition begins under the action of high-frequency microwaves to generate F-doped SiO 2 , reducing the refractive index. Introduce a small amount of C initially 2 f 6 +SF 6 , to deposit a buffer layer, after a period of time, the C 2 f 6 +SF 6 Adjust the dosage to the maximum, then C 2 f 6 +SF 6 content gradually decreased, GeCl 4 The content gradually increased, and the deposition took 8 hours to complete the entire deposition process.

[0069] (2) After the deposition is completed, transfer the liner to the shrink furnace and shrink at 2100°C. The liner rotates at a speed of 60r / min, and the temperature program is set. After the seal is formed from the middle, it expands to both sides and reaches the center. The channels are completely clos...

Embodiment 3

[0072] (1) A quartz glass liner with a diameter of 50mm and a thickness of 4mm is installed on the PCVD equipment and injected with SiCl 4 、GeCl 4 , O 2 gas, the heating temperature of the furnace body is 1200°C, and the deposition begins under the action of high-frequency microwaves to generate Ge-doped SiO 2 , the initial access to GeCl 4 The content gradually increases, and the refractive index increases. After 2 hours of deposition, GeCl 4 When the amount reaches a certain value, it gradually decreases, and at the same time gradually adds C 2 f 6 +CF 4 +POCl 3 , a subsequent deposition time of 8 hours, the final GeCl 4 Dosage to minimum value, C 2 f 6 +CF 4 +POCl 3 Use the amount to the maximum value to end the entire deposition process, and the total deposition time is 10 hours.

[0073] (2) After the deposition is completed, transfer the liner to the shrink furnace and shrink at 2000°C. The liner rotates at a speed of 40r / min, and the temperature program is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com