Transformer substation OPGW terminal reserved cable and manufacturing method thereof

A technology for reserved cables and substations, which is applied in the direction of optical fiber/cable installation, optics, light guide, etc. It can solve problems such as hidden dangers of power grid backbone communication optical cable line equipment, threats to safe production of smart grids, inter-turn contact discharge, etc., to achieve the solution of reserved The effect of eliminating insulation problems between cable turns, eliminating hidden dangers of equipment, and reducing maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

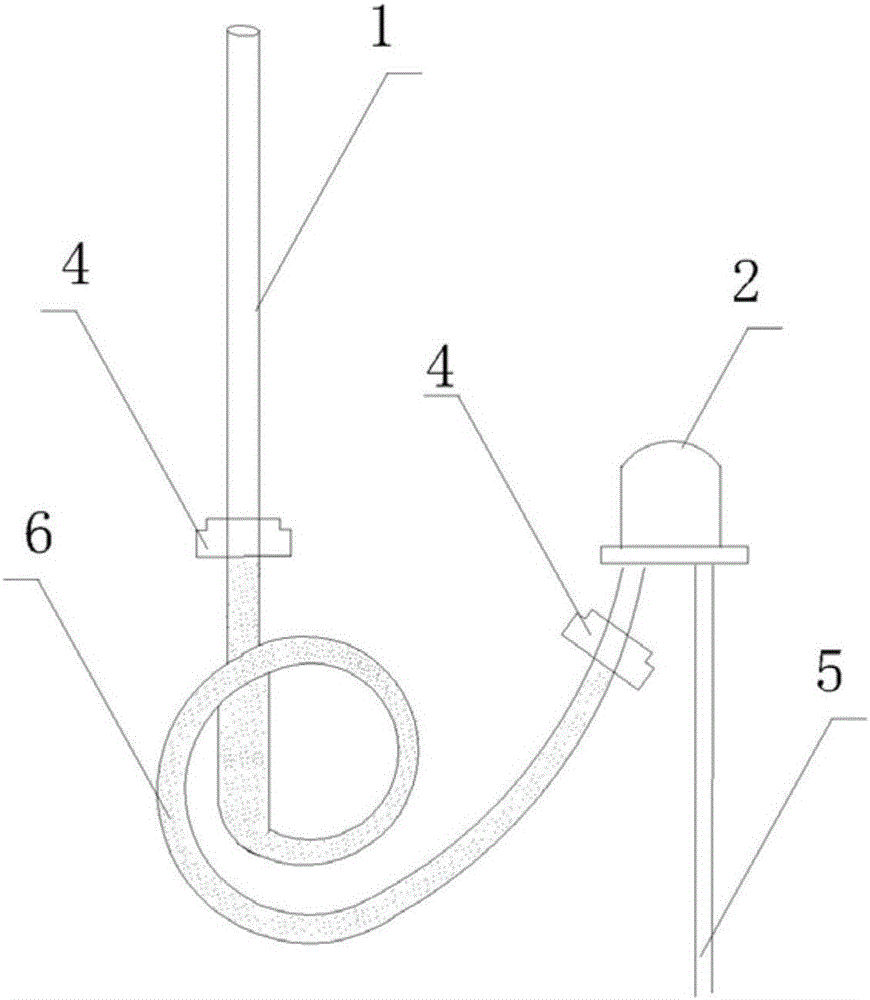

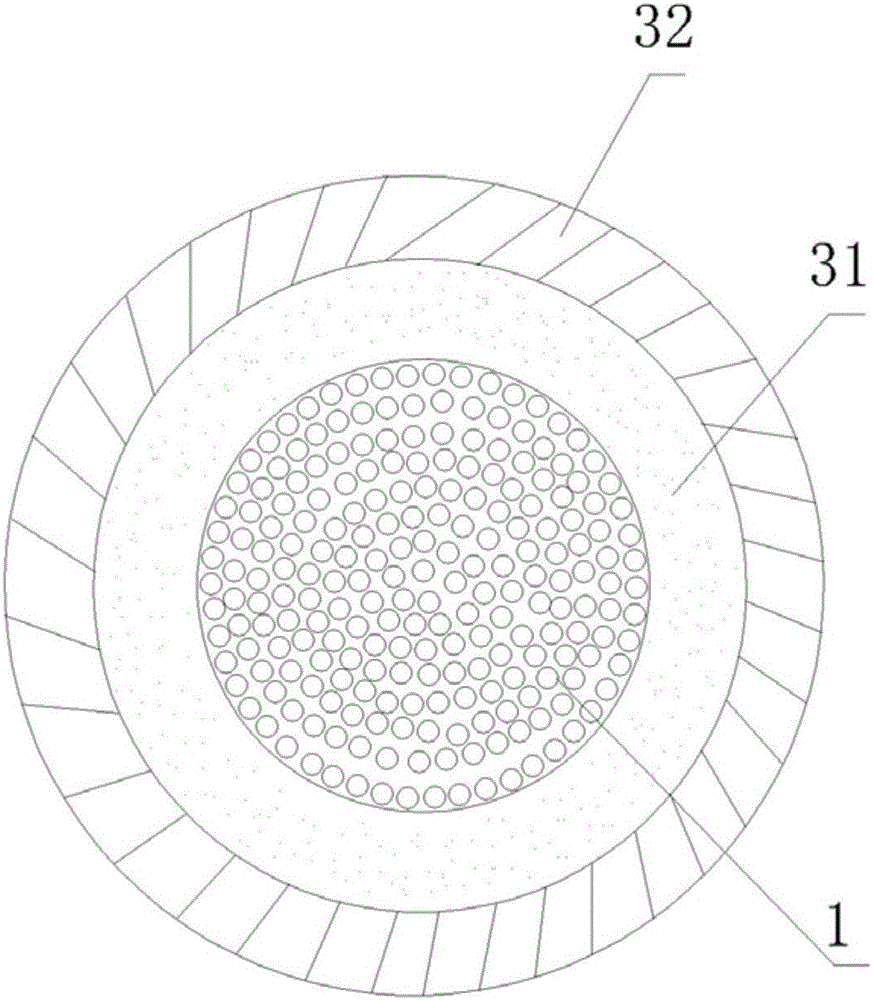

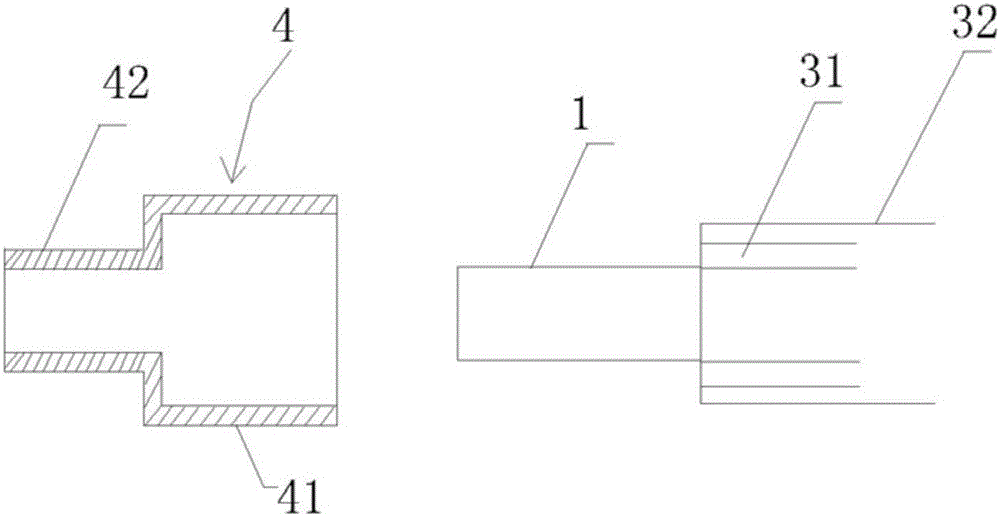

[0015] Such as figure 1 , 2 As shown, the OPGW terminal reserved cable of this substation is provided with an insulating protective layer 3 at the tail end of the OPGW terminal reserved cable 1 to form an OPGW optical cable 6 with an insulating sheath layer. The insulating protective layer includes a waterproof material 31 and an insulating protective sheath 32. The waterproof material is applied waterproof glue or wound insulating tape, put the insulating protective sleeve on the waterproof material, and heat shrink the insulating protective sleeve through heat shrinking treatment equipment, so as to eliminate the air in the insulating protective sleeve. The tail end of the OPGW optical cable in the insulation sheath layer is connected to the OPGW optical cable junction box 2 . In addition, this optical cable splice closure has a guide cable 5 .

[0016] In the present invention, the finished OPGW cable that has already been produced is put on the extruding production line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com