High resolution X ray, gamma ray and electron ray microscope

An electron ray and high-resolution technology, which is applied in the field of microscope systems, can solve problems such as the inability to realize large-angle refraction and the inability to form a microscopic magnification system, and achieve high resolution and improve the resolution limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

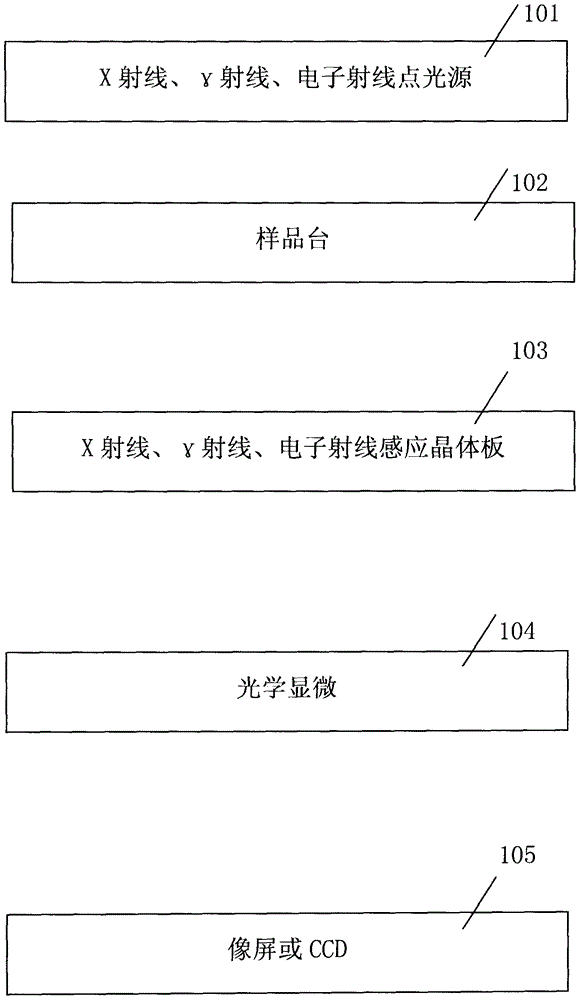

[0051] Preferred Example 1: Principle Block Diagram

[0052] Such as figure 1 Shown, X-ray, gamma ray, electron ray microscope is by X-ray, gamma ray, electron ray point light source (101); Sample stage (102); X ray, gamma ray, electron ray crystal induction plate (103); micro-magnification system (104); composed of image screen or CCD (105);

[0053] X-ray, gamma ray, electron ray point light source (101), "point light source" passes through the sample on the sample stage (102), forms enlarged transmission image on X-ray, gamma ray, electron ray crystal induction plate (103); X X-ray, gamma ray, electron ray crystal induction plate (103), the crystal induction plate (103) converts X-ray, gamma ray, electron ray image into visible light image; the visible light image is amplified by optical microscope magnification system (104) again Display on image screen or CCD (105);

[0054] There are two sets of enlarged imaging systems in the present invention: (1) by X-ray, γ-ray, e...

example 2

[0059] Preferred Example 2: System Resolution Analysis:

[0060] Due to the diffraction characteristics of waves, according to the Abbe imaging principle, the imaging resolution of waves is:

[0061] δ=0.61λ / (n*sinα)

[0062] λ is the wavelength of illumination light; n is the refractive index; α lens numerical aperture;

[0063] The wavelength of X-rays is 0.01A-100A, and the wavelength of gamma rays is electromagnetic waves less than 0.01A wavelength;

[0064] Due to the diffraction of waves, there will be diffraction spots; it will affect the further improvement of the resolution of the existing optical micromagnification system mirror and electron microscope;

[0065] Method 1 uses X-rays and γ-rays with shorter wavelengths, thereby greatly improving the resolution limit of the microscope;

[0066] Method 2 uses electron rays with higher energy and shorter wavelength, thereby greatly improving the resolution limit of the microscope.

example 3

[0067] Preferred Example 3: Working Principle

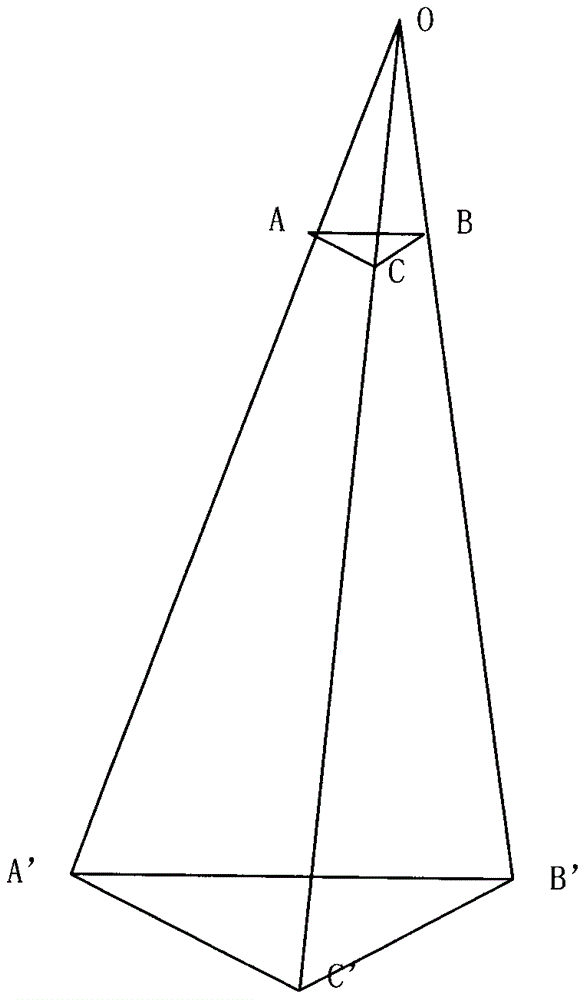

[0068] Resolution X-ray, γ-ray, and electron ray microscopes consist of two sets of magnification systems; the first magnification system uses X-ray, γ-ray, and electron ray point sources to geometrically magnify the object and display it on the imaging plate; the second set The magnification system enlarges the image on the imaging board; the magnification of the whole system is the magnification of the first set of magnification system × the magnification of the second set of magnification system;

[0069] The first magnification system, method 1, uses a point light source to magnify the sample by using the characteristics of the linear propagation of light; method 2: uses the electronic lens magnification system to magnify the sample;

[0070] The crystal sensing plate (103) converts the X-ray image into a visible light image;

[0071] The crystal sensing plate (103) converts the γ-ray image into a visible light image;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com