Backlight modules and liquid crystal display equipment

A technology of backlight module and liquid crystal panel, applied in optics, nonlinear optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

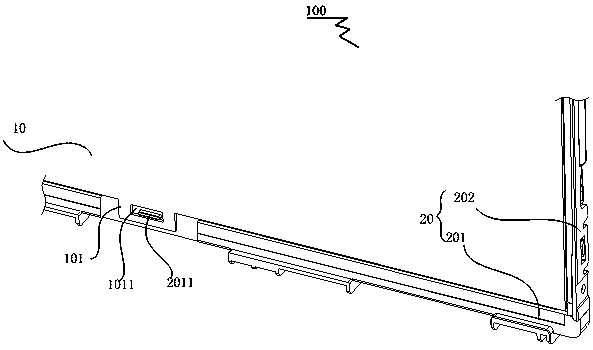

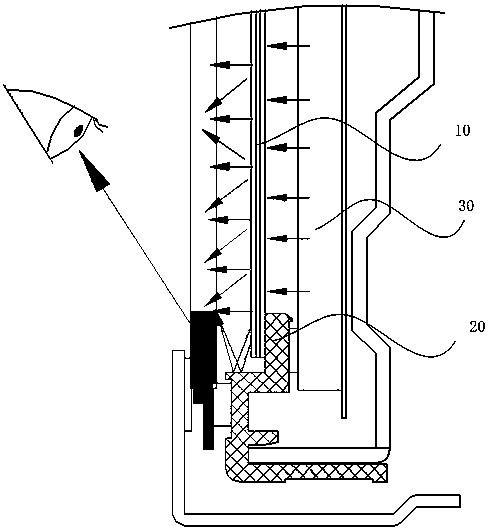

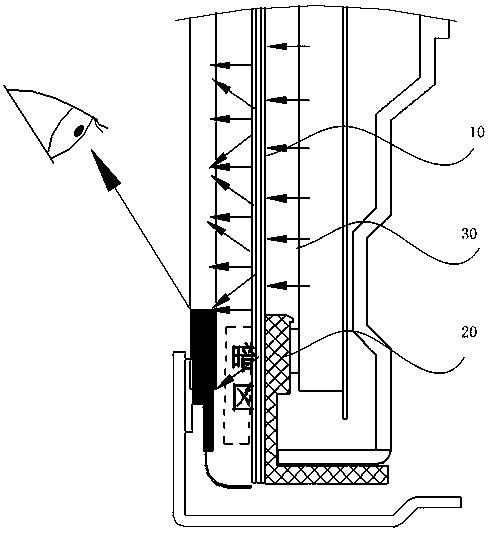

[0032] image 3 It is a schematic diagram of fixing the diaphragm of the backlight module in Embodiment 1 of the present invention; Figure 4 a is a schematic diagram of the A-A cross-section of the backlight module in Embodiment 1 of the present invention; Figure 5 It is a schematic diagram of the C-C section of the backlight module in Embodiment 1 of the present invention; Figure 6 It is a B-B cross-sectional schematic view of the backlight module in Embodiment 1 of the present invention. Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, Embodiment 1 of the present invention provides a backlight module 200 , including a fixing frame 70 and an optical film set 60 .

[0033]The backlight module 200 in the first embodiment can be applied to a liquid crystal display device. Specifically, the liquid crystal panel is placed on the backlight module 200, and the backlight module 200 and the liquid crystal panel are assembled together by a fixing device to form...

Embodiment 2

[0046] Such as Figure 9 As shown, the difference from Embodiment 1 is that the film edge protrusion 6031 of the second optical film 603 , the film edge protrusion 6021 of the first optical film 602 , and the film edge protrusion 6011 of the brightness enhancement film 601 and the protruding portion 6041 of the film edge of the third optical film 604 sequentially form a staggered layer structure interlaced with each other. Wherein, the film edge protrusion 6011 of the incremental film 601 is the same shape and size as the film edge protrusion 6031 of the second optical film 603, and the film edge protrusion 6021 of the first optical film 602 is the same as the third optical film edge protrusion 6021. The diaphragm edge protrusions 6041 of the diaphragm 604 are identical in shape and size.

[0047] Further, the film edge protrusion 6011 of the incremental film 601 is larger in area than the film edge protrusion 6021 of the first optical film 602 .

[0048] On the one hand, th...

Embodiment 3

[0051] Such as Figure 10 As shown, the same as the second embodiment, the film edge protrusion 6031 of the second optical film 603, the film edge protrusion 6021 of the first optical film 602, and the film edge protrusion 6011 of the brightness enhancement film 601 and the protruding portion 6041 of the film edge of the third optical film 604 sequentially form a staggered layer structure interlaced with each other. Wherein, the film edge protrusion 6011 of the incremental film 601 is the same shape and size as the film edge protrusion 6031 of the second optical film 603, and the film edge protrusion 6021 of the first optical film 602 is the same as the third optical film edge protrusion 6021. The diaphragm edge protrusions 6041 of the diaphragm 604 are identical in shape and size.

[0052] The difference from the second embodiment is that the film edge protrusion 6011 of the incremental film 601 is smaller in area than the film edge protrusion 6021 of the first optical film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com