Side-wall-coarsened high-brightness light emitting diode and preparation method thereof

A light-emitting diode, high-brightness technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problems of many production steps, high production costs, complex processes, etc., to improve product reliability, reduce refractive index difference, and improve luminescence. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

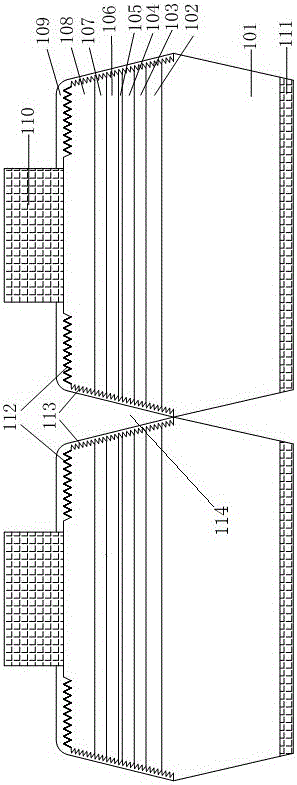

[0028] A high-brightness light-emitting diode with roughened side walls, including a gallium arsenide permanent substrate 101 , on a GaAs permanent substrate 101 set above in turn with N-GaAs The buffer layer 102 、 AlAs / AlGaAs reflective layer 103 、 N-AlGaInP lower limiting layer 104 、 AlGaInP active layer 105 、 P-AlGaInP upper limit layer 106 、 P-GaInP The buffer layer 107 and P-GaP Coarsening layer 108 , P-GaP Coarsening layer 108 Include P-GaP Front Coarsening Layer 112 and P-GaP roughened sidewall 113 two parts, in P-GaP Front Coarsening Layer 112 set the first electrode on 110 , P-GaP roughened sidewall 113 presented V groove structure, window layer 109 for SiN Optical Thin Films, Permanent Substrates on Gallium Arsenide 101 A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com